A kind of mcm-41 ordered mesoporous material and preparation method thereof

A MCM-41, mesoporous material technology, applied in chemical instruments and methods, molecular sieve compounds, inorganic chemistry, etc., can solve the cumbersome preparation process of mesoporous materials, restrict the development and application of mesoporous materials, energy-consuming mesoporous materials specific surface area and other problems, to achieve the effect of improving comprehensive utilization rate, concentrated pore size distribution, and good pore performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

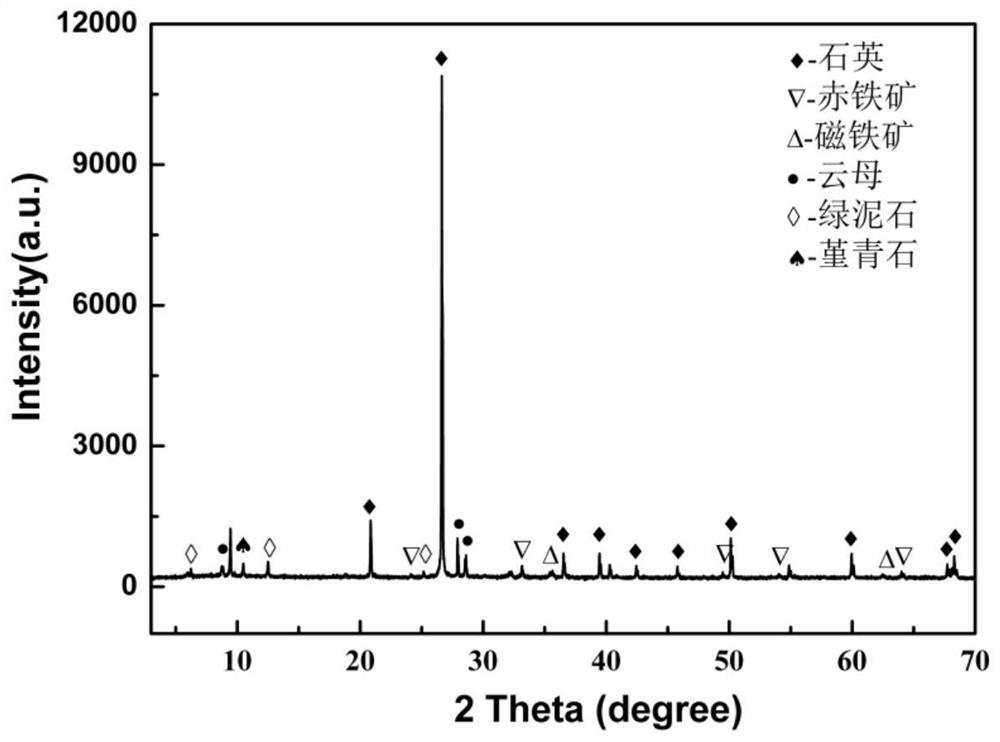

[0036] (1) Using iron tailings as raw materials, the chemical composition analysis of iron tailings is shown in Table 1, and the phase composition is shown in the appendix figure 1As shown, 8 mol / L hydrochloric acid solution is the leaching agent. According to the ratio of solid-liquid ratio of 1:1.5 (g / mL), iron tailings and hydrochloric acid aqueous solution are mixed, and the turbid liquid is obtained after magnetic stirring at 150 ° C for 3 hours. , after cooling it to room temperature, carry out suction filtration, wash the solid product obtained by suction filtration with deionized water to neutrality (same pH as deionized water), and dry at a temperature of 60 ° C to obtain acid-insoluble slag, acid-insoluble slag The chemical composition analysis is shown in Table 1.

[0037] (2) using the acid-insoluble residue obtained in step (1) as a raw material, the mass ratio of the acid-insoluble residue and sodium hydroxide is 1:2.2 (g / g), and the solid matter (acid-insoluble ...

Embodiment 2

[0044] (1) Using iron tailings as raw materials, 4 mol / L sulfuric acid solution as leaching agent, taking iron tailings and hydrochloric acid aqueous solution according to the ratio of solid-liquid ratio of 1:3 (g / mL) and mixing, at a temperature of 100 ° C After magnetic stirring for 6 hours, a turbid liquid was obtained, which was cooled to room temperature and then subjected to suction filtration. The solid product obtained by suction filtration was washed with deionized water until neutral (the same pH as deionized water), and dried at a temperature of 60 ° C to obtain Acid insoluble residue.

[0045] (2) using the acid-insoluble residue obtained in step (1) as a raw material, the mass ratio of the acid-insoluble residue and sodium hydroxide is 1:2.2 (g / g), and the solid matter (acid-insoluble residue and sodium hydroxide) and deionized The solid-to-liquid ratio of water is 1:2 (g / mL), mix acid-insoluble residue, sodium hydroxide and deionized water, heat it with water at ...

Embodiment 3

[0049] (1) Using iron tailings as raw materials, 2 mol / L hydrochloric acid solution as leaching agent, taking iron tailings and hydrochloric acid aqueous solution according to the ratio of solid-liquid ratio of 1:6 (g / mL) and mixing, at a temperature of 120 ° C After magnetic stirring for 5 hours, a turbid liquid was obtained, which was cooled to room temperature and then subjected to suction filtration. The solid product obtained by suction filtration was washed with deionized water until neutral (same pH as deionized water), and dried at a temperature of 60 ° C to obtain Acid insoluble residue.

[0050] (2) using the acid-insoluble residue obtained in step (1) as a raw material, the mass ratio of the acid-insoluble residue and sodium hydroxide is 1:2.2 (g / g), and the solid matter (acid-insoluble residue and sodium hydroxide) and deionized The solid-to-liquid ratio of water is 1:2 (g / mL), mix acid-insoluble residue, sodium hydroxide and deionized water, heat it with water at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com