Flocculation, swirling, precipitation and filtration integrated sewage treatment equipment

A technology of sewage treatment equipment and filter cylinder, which is applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment equipment, filtration treatment, etc. One-time discharge standard or direct reuse, low purification efficiency and other problems, to achieve good novelty and practicability, compact structure, less floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

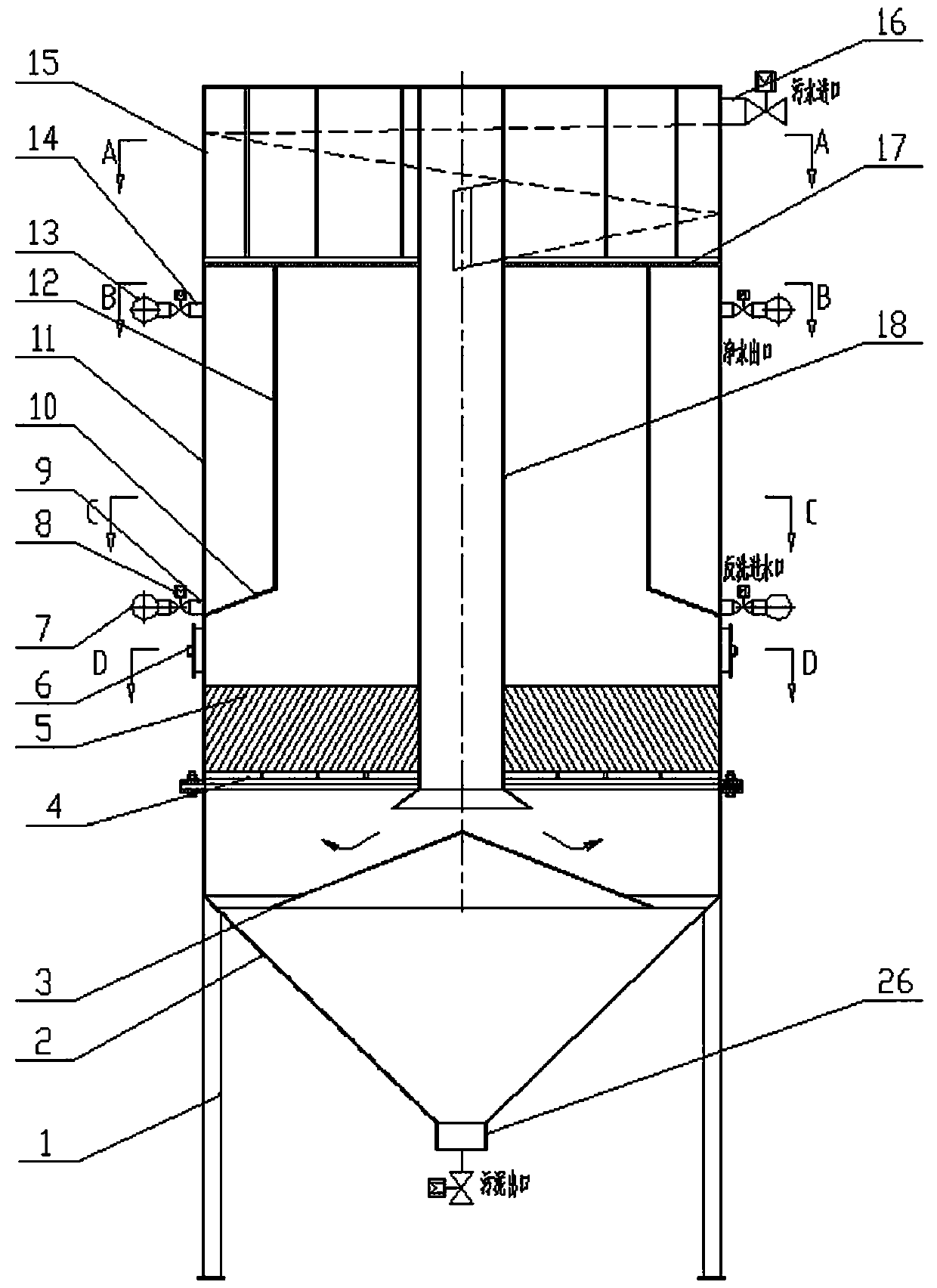

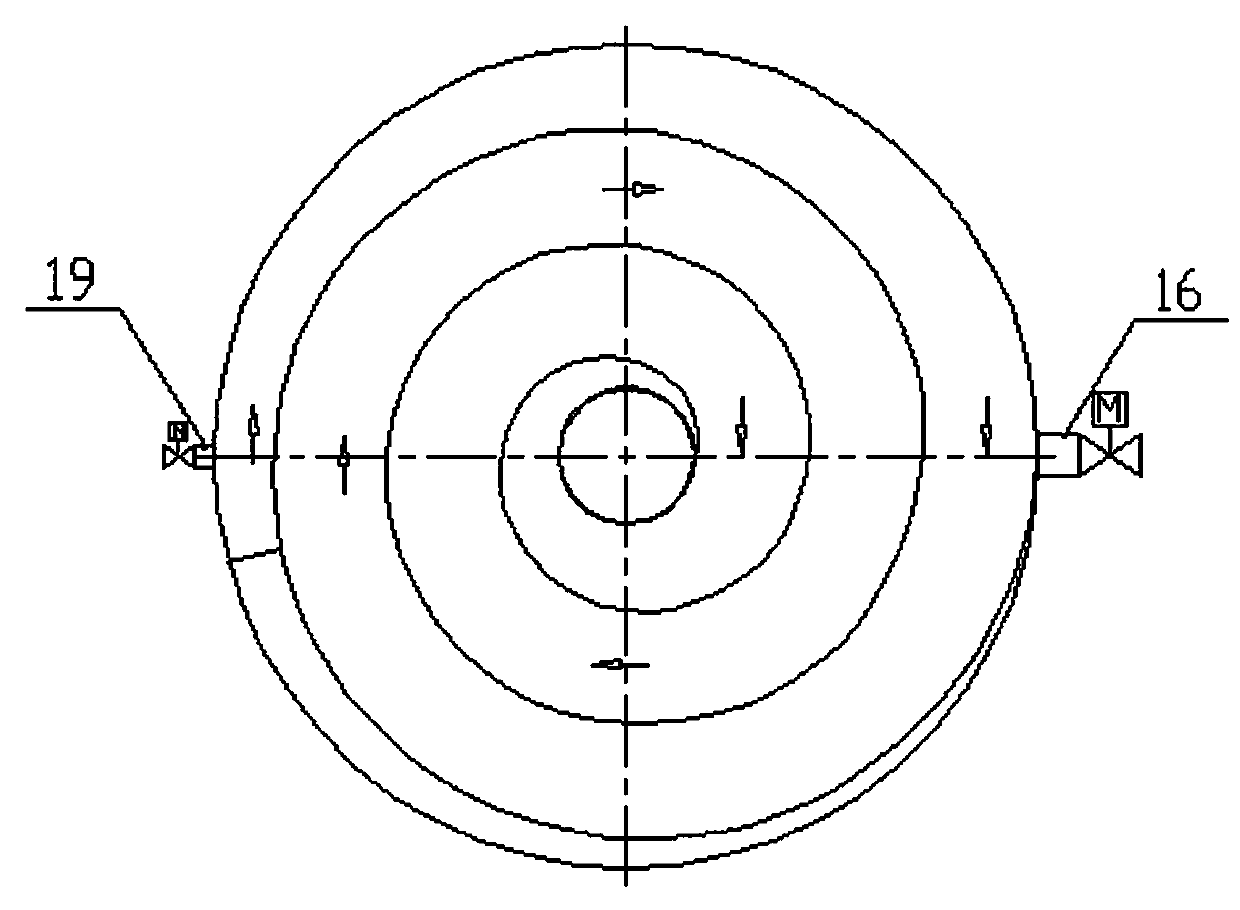

[0037] See Figure 1 to Figure 5 This embodiment includes an inner cylinder 18, a filter cylinder 12 and an outer cylinder 11 coaxially nested from inside to outside. The top of the filter cylinder 12 and the outer cylinder 11 is provided with a top plate 17, a cyclone flocculation tank 15 is installed above the top plate 17, and the upper end of the inner cylinder 18 extends into the cyclonic flocculation tank 15 and is connected to the cyclonic flocculation tank 15 The tank body is concentric, the part of the inner cylinder 18 extending into the cyclone flocculation tank 15, and the connection with the top plate is provided with a sewage inlet tangential to the outer diameter of the inner cylinder; below the filter cylinder 12, the bottom of the inner cylinder 18 is connected to The bottom of the outer cylinder 11 is provided with an inclined tube sedimentation packing layer 5, the inclined tube sedimentation packing layer 5 is installed on the inclined tube packing bracket 4...

Embodiment 2

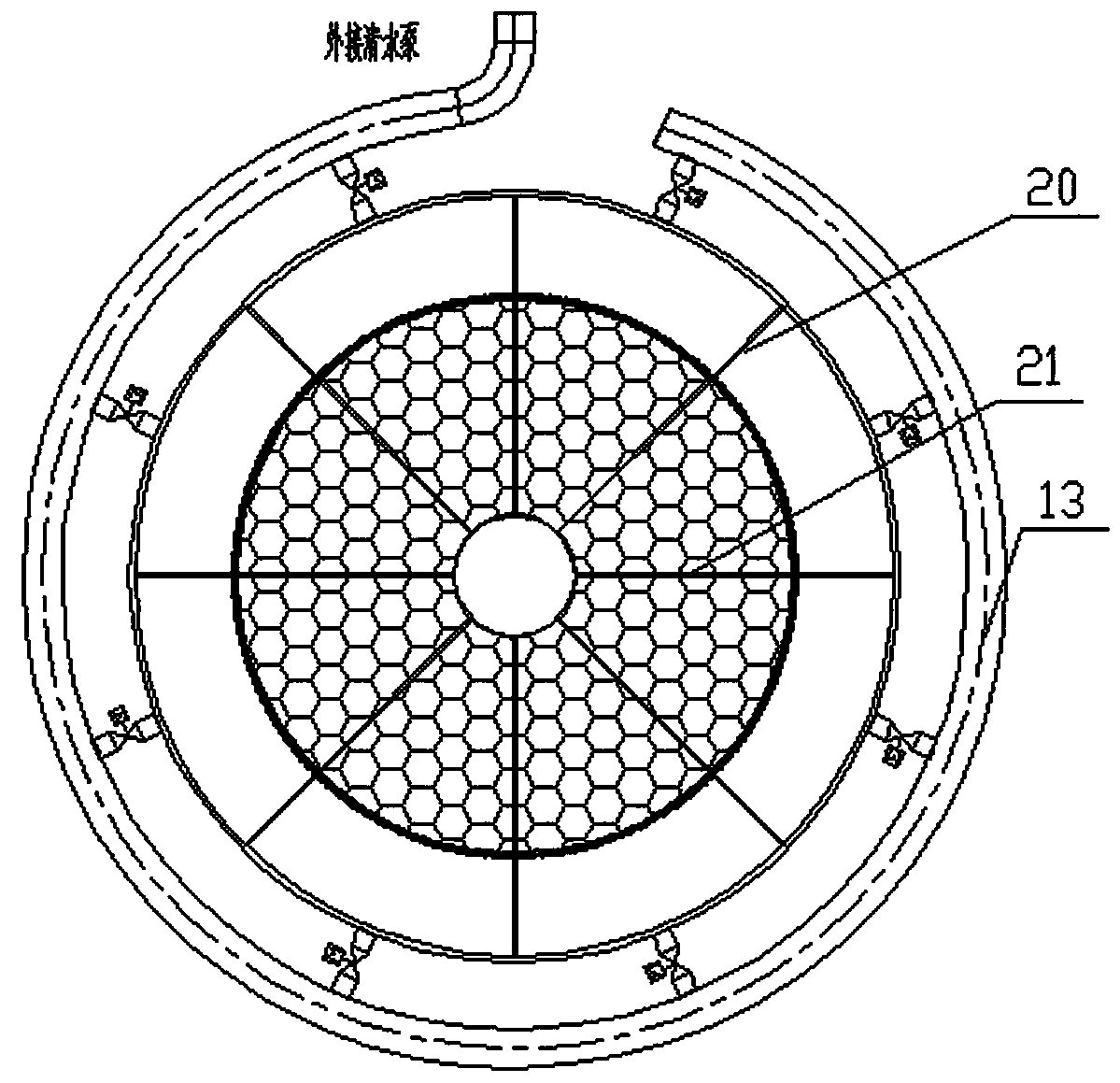

[0041] See Image 6 , Figure 7 The structure of this embodiment is basically the same as that of the first embodiment. The difference lies in the arrangement and structure of the filter layer.

[0042] From Image 6 , Figure 7 It can be seen that this embodiment includes an inner cylinder 18 and an outer cylinder 11 that are coaxially nested from the inside to the outside; a top plate 17 is provided on the top of the outer cylinder 11, and a cyclone flocculation tank 15 is installed above the top plate 17, and the inner The upper end of the cylinder 18 extends into the cyclonic flocculation tank 15 and is concentric with the cyclonic flocculation tank 15; the upper part of the cyclonic flocculation tank 15 is provided with a sewage inlet 16 and a flocculant filling port, and the inner cylinder 18 extends into In the cyclone flocculation tank 15, there is a sewage inlet tangential to the outer diameter of the inner cylinder at the connection with the top plate; between the bottom...

Embodiment 3

[0046] See Picture 10 In this embodiment, on the basis of the second embodiment, the circular filter layer is eliminated as needed. Above the inclined pipe sedimentation packing layer 5 is the clean water outlet chamber. The clean water outlet chamber is divided into several independent clean water outlets by partitions. In the water compartment, the position of the outer cylinder corresponding to each water purification compartment is respectively provided with an overhaul manhole and a common interface for the purification water outlet and the reverse cleaning water inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com