A kind of preparation method of modified coral sand concrete

A coral sand and concrete technology, which is applied in the field of preparation of modified coral sand concrete, can solve problems such as high cost and complicated steps, and achieve the effects of increasing service life, enhancing compressive and flexural properties, and protecting steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

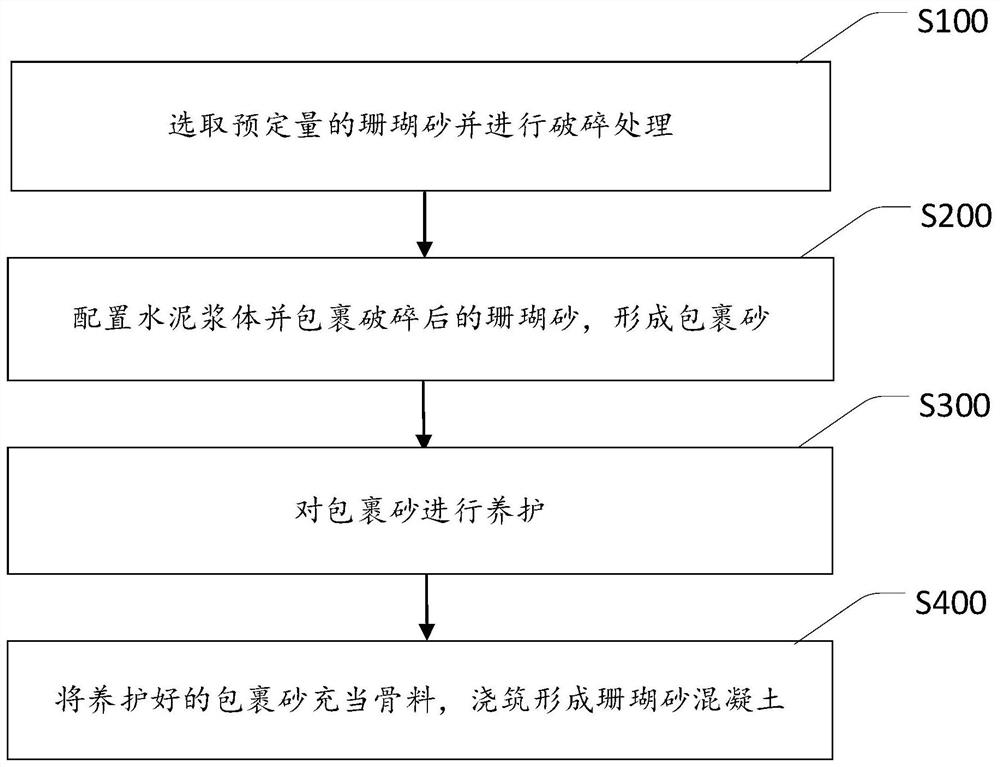

Method used

Image

Examples

Embodiment 1

[0058] In addition, in order to explore the most suitable water-cement ratio of cement paste, and the mass ratio of coral sand and cement paste, the present invention provides embodiment one as follows:

[0059] Repeat the above steps to explore the coral sand wrapping test, and the results are shown in Table 1. It is preliminarily concluded that a certain amount of coral sand corresponds to the appropriate range of water-cement ratio and the amount of mortar, as well as the difference between primary wrapping and secondary wrapping . Table 2 and Table 3 simply define the evaluation criteria for the thickness of the cement paste package on coral sand and the amount of remaining cement paste. Also, Table 4 and Table 5 show the titration results of Cl- (chloride ion) precipitation. Therefore, through a series of investigations of embodiment one, what the present invention finally chose is that the water-cement ratio of cement slurry is 0.4, and the mass ratio of coral sand and ...

Embodiment 2

[0074] Simultaneously, utilize above-mentioned steps to obtain the performance of concrete test block in order to test, the present invention provides embodiment two as follows:

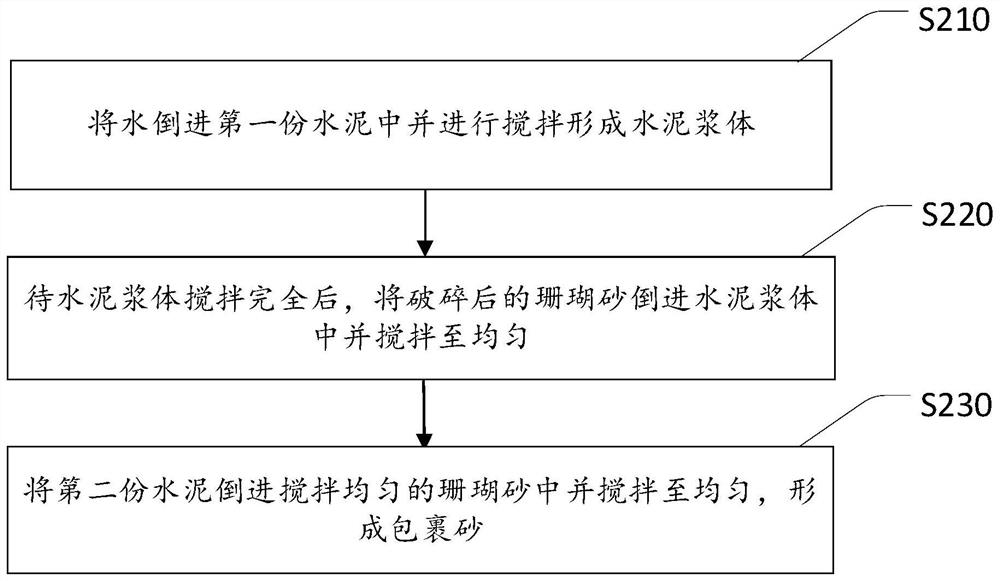

[0075] 1. Get a certain amount of broken coral aggregate, deionized water, fast hardening and early strength according to the test ratio of Example 1 (coral sand 100g, cement slurry amount 75g, water-cement ratio 0.4, cement will be divided into two equal parts) High alumina phase cement (divided into 2 equal parts), standard sand;

[0076] 2. Mix half of the cement with deionized water to make a slurry, and stir evenly;

[0077] 3. Pour the aggregate into the slurry for stirring. After a period of time, pour the other half of the cement into the mixer for stirring. After stirring evenly, carry out maintenance;

[0078] 4. Use the wrapped aggregate to pour the test block. There are three samples in each group, and the size of the test block is 40X40X160mm. The comparative test data obtained are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com