A kind of epoxy resin-based concrete for building and its preparation process

An epoxy resin and concrete technology, applied in the construction field, can solve the problems of poor weather resistance, building collapse, steel corrosion, etc., and achieve the effect of high hydrophobic performance and high weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The specific preparation process of fluorosilanized zeolite powder is as follows:

[0035]Step 1: Dissolve 71g of acrylamide in 200mL of water to obtain an acrylamide solution;

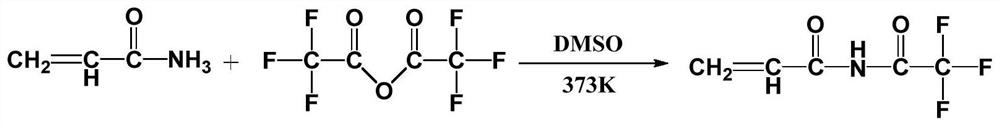

[0036] Step 2: Add 125g of trifluoroacetic anhydride and 200mL of dimethyl sulfoxide to the reaction vessel, stir and mix evenly, then slowly add the acrylamide solution prepared in step 1 dropwise, and raise the temperature while adding, and the heating time speed is controlled at 1°C per minute, stop the temperature rise until the temperature rises to 100°C, and then react at a constant temperature for 8 hours to obtain fluoroalkylated acrylamide;

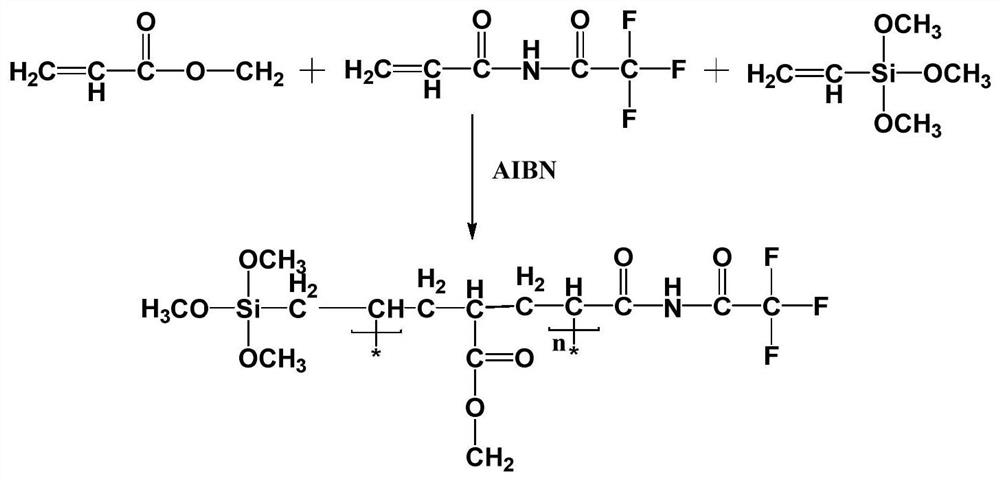

[0037] Step 3: Add 96g of methyl methacrylate into the ethanol solution, then pour the mixed solution into the flask, and add 200g of zeolite powder to it at the same time, stir and mix evenly, put the flask into an ice-water bath, and vacuumize for 1 hour while Stir while vacuuming, then stop vacuuming, take out the flask and put it in a room te...

Embodiment 2

[0040] The specific preparation process of fluorosilanized zeolite powder is as follows:

[0041] Step 1: Dissolve 71g of acrylamide in 200mL of water to obtain an acrylamide solution;

[0042] Step 2: Add 125g of trifluoroacetic anhydride and 200mL of dimethyl sulfoxide to the reaction vessel, stir and mix evenly, then slowly add the acrylamide solution prepared in step 1 dropwise, and raise the temperature while adding, and the heating time speed is controlled at 1°C per minute, stop the temperature rise until the temperature rises to 100°C, and then react at a constant temperature for 8 hours to obtain fluoroalkylated acrylamide;

[0043] Step 3: Add 98g of methyl methacrylate into the ethanol solution, then pour the mixed solution into the flask, and add 200g of zeolite powder to it at the same time, stir and mix evenly, put the flask into an ice-water bath, and vacuumize for 1h, while Stir while vacuuming, then stop vacuuming, take out the flask and put it in a room temp...

Embodiment 3

[0046] The specific preparation process of aging-resistant grafted rubber powder is as follows:

[0047] ① Add 1.1kg of rubber powder into 2L of 15% sodium hydroxide solution, heat up to 50°C, stir for 1 hour, then filter, and add the filtered rubber powder into 2L of 5% nitric acid solution. After heating up to 60°C, stir and react for 30 minutes, filter, wash with sodium carbonate solution until neutral, and dry to obtain pretreated rubber powder;

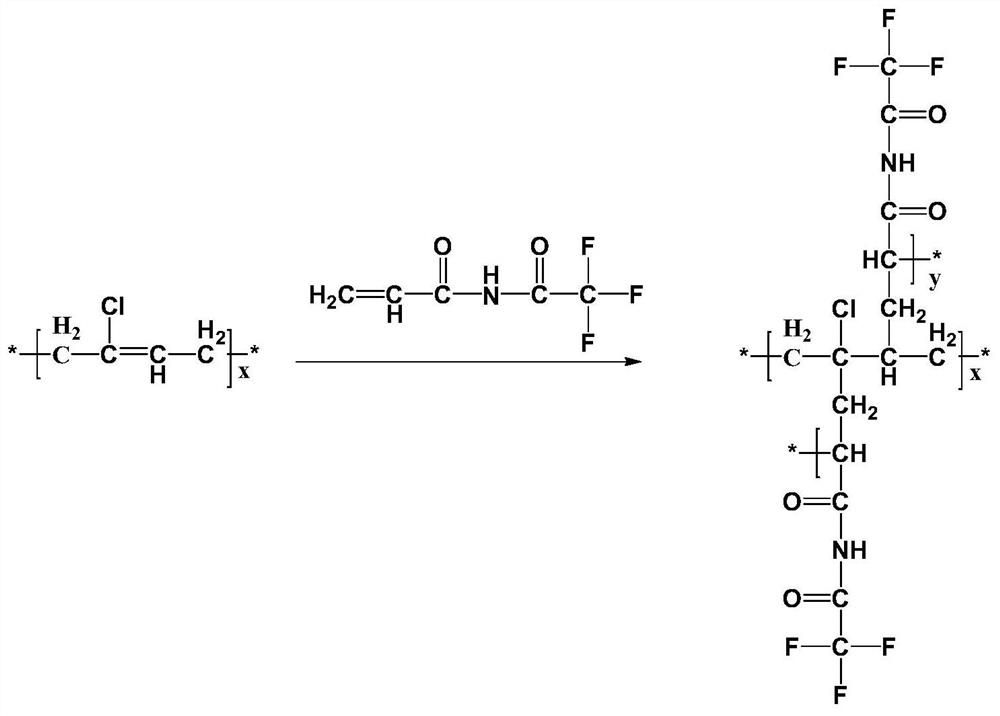

[0048] ②Add 1kg of pretreated rubber powder to acetone, then add 355g of azobisisobutyronitrile to it, raise the temperature to 90°C, add 680g of fluoroalkylated acrylamide dropwise, react for 5 hours after the dropwise addition, and then raise the temperature to 120°C ℃, continue to add 355g of azobisisobutyronitrile, and react for 2 hours to obtain aging-resistant grafted starch glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com