A kind of negative ion anti-pressure building material and preparation method thereof

A technology for building materials and negative ions, applied in the field of negative ion compression-resistant building materials and their preparation, can solve the problems of ineffective release of negative ions, poor sound insulation effect and high thermal insulation coefficient, and achieve the elimination of indoor odor and various harmful gases and sound insulation effect. Good, low thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

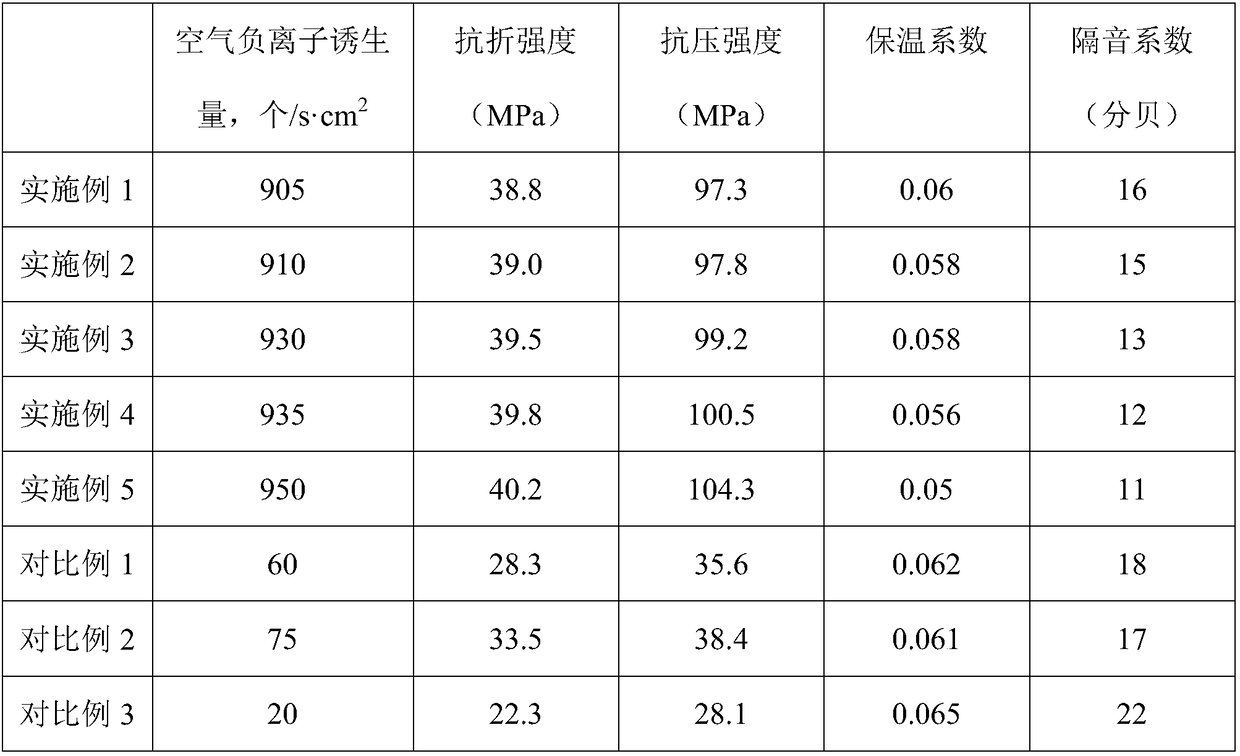

Examples

Embodiment 1

[0017] In the embodiment of the present invention, an anion-resistant building material is composed of the following raw materials in parts by weight: 33 parts of lignin, 18 parts of hydroxyapatite, 15 parts of chitosan, 9 parts of hexamethylenetetramine, 1 part concentrated sulfuric acid.

[0018] Mix concentrated sulfuric acid with 9 times its mass of deionized water to prepare a sulfuric acid solution; add hexamethylenetetramine to 10 times its mass of deionized water to prepare a hexamethylenetetramine solution. The lignin was pulverized, passed through a 200-mesh sieve, placed in a sulfuric acid solution, heated to 68° C., and stirred at this temperature for 35 minutes to obtain a mixture A. Mix and grind hydroxyapatite and chitosan, pass through a 200-mesh sieve, add hexamethylenetetramine solution and mix, raise the temperature to 80° C., and stir at this temperature for 30 minutes to prepare mixture B. Mix mixture A and mixture B, heat and stir at 92°C for 55 minutes,...

Embodiment 2

[0020] In the embodiment of the present invention, a negative ion anti-pressure building material is composed of the following raw materials in parts by weight: 41 parts of lignin, 26 parts of hydroxyapatite, 23 parts of chitosan, 17 parts of hexamethylenetetramine, 5 parts of concentrated sulfuric acid.

[0021] Mix concentrated sulfuric acid with 9 times its mass of deionized water to prepare a sulfuric acid solution; add hexamethylenetetramine to 10 times its mass of deionized water to prepare a hexamethylenetetramine solution. The lignin was pulverized, passed through a 200-mesh sieve, placed in a sulfuric acid solution, heated to 68° C., and stirred at this temperature for 40 minutes to obtain a mixture A. Mix and grind hydroxyapatite and chitosan, pass through a 200-mesh sieve, add hexamethylenetetramine solution and mix, raise the temperature to 80° C., and stir at this temperature for 30 minutes to prepare mixture B. Mix mixture A and mixture B, heat and stir at 92°C ...

Embodiment 3

[0023] In the embodiment of the present invention, an anion-resistant building material is composed of the following raw materials in parts by weight: 35 parts of lignin, 20 parts of hydroxyapatite, 17 parts of chitosan, 11 parts of hexamethylenetetramine, 2 parts of concentrated sulfuric acid.

[0024] Mix concentrated sulfuric acid with 9 times its mass of deionized water to prepare a sulfuric acid solution; add hexamethylenetetramine to 10 times its mass of deionized water to prepare a hexamethylenetetramine solution. The lignin was pulverized, passed through a 200-mesh sieve, placed in a sulfuric acid solution, heated to 68°C, and stirred at this temperature for 38 minutes to obtain a mixture A. Mix and grind hydroxyapatite and chitosan, pass through a 200-mesh sieve, add hexamethylenetetramine solution and mix, raise the temperature to 80° C., and stir at this temperature for 30 minutes to prepare mixture B. Mix mixture A and mixture B, heat and stir at 92°C for 58 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com