Compression-resistant fracture-resistant and flame-retardant plastic foaming material and preparation process thereof

A foamed material and flame-retardant plastic technology, which is applied in the field of compression-resistant and flexural-resistant flame-retardant plastic foamed materials and the preparation process thereof, and can solve the The flexural efficiency fails to meet the highest standard requirements, and the compressive and flexural effect cannot meet the highest standard requirements, so as to achieve the effect of enhancing the compressive and flexural performance, reducing the use of flame retardants, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 discloses a compressive and flexural flame-retardant plastic foam material and its preparation process.

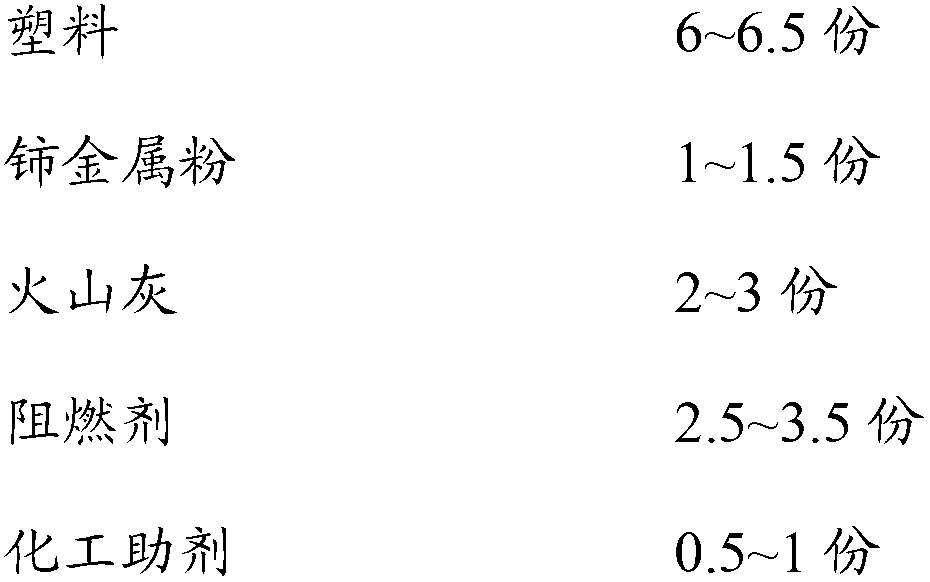

[0022] The foaming material includes the following components according to the mass ratio:

[0023]

[0024] Here, the plastic is high-pressure low-density polyethylene (in other embodiments, the plastic is at least one of high-pressure low-density polyethylene, low-pressure high-density polyethylene, high-low pressure composite polyethylene, and ethylene-vinyl acetate copolymer);

[0025] Chemical additives include the following components by mass: 0.39 parts of azodicarbonamide, 0.06 parts of zinc oxide with a purity of 99.5%~99.7%, 0.03 parts of zinc stearate and 0.02 parts of W-8035 non-ionic crosslinking agent share. (In other embodiments, zinc stearate is at least one of solid and water-based zinc stearate, and the nonionic crosslinking agent is W-8035, W-8130 and W-8235 nonionic crosslinking agent at least one of the

[0026] The particle s...

Embodiment 2

[0033] Embodiment 2 discloses a compressive and flexural flame-retardant plastic foam material and its preparation process.

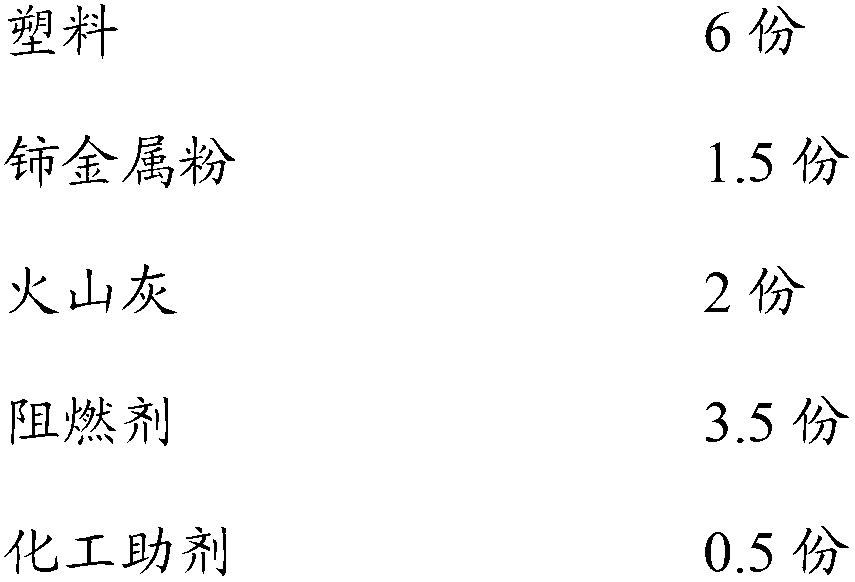

[0034] The foaming material includes the following components according to the mass ratio:

[0035]

[0036]

[0037] Here, the plastic is high-pressure low-density polyethylene (in other embodiments, the plastic is at least one of high-pressure low-density polyethylene, low-pressure high-density polyethylene, high-low pressure composite polyethylene, and ethylene-vinyl acetate copolymer);

[0038] Chemical additives include the following components by mass: 0.66 parts of azodicarbonamide, 0.14 parts of zinc oxide with a purity of 99.5%~99.7%, 0.11 parts of zinc stearate and 0.09 parts of W-8035 non-ionic crosslinking agent share. (In other embodiments, zinc stearate is at least one of solid and water-based zinc stearate, and the nonionic crosslinking agent is W-8035, W-8130 and W-8235 nonionic crosslinking agent at least one of the

[0039] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com