Ascending pipe pneumatic blowing and sweeping device and method

A dynamic, sand suction pipe technology, used in the discharge device of dry distillation gas, the petroleum industry, heating of coke ovens, etc. Small force and other problems, to achieve the effect of reducing air pollution, high reliability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

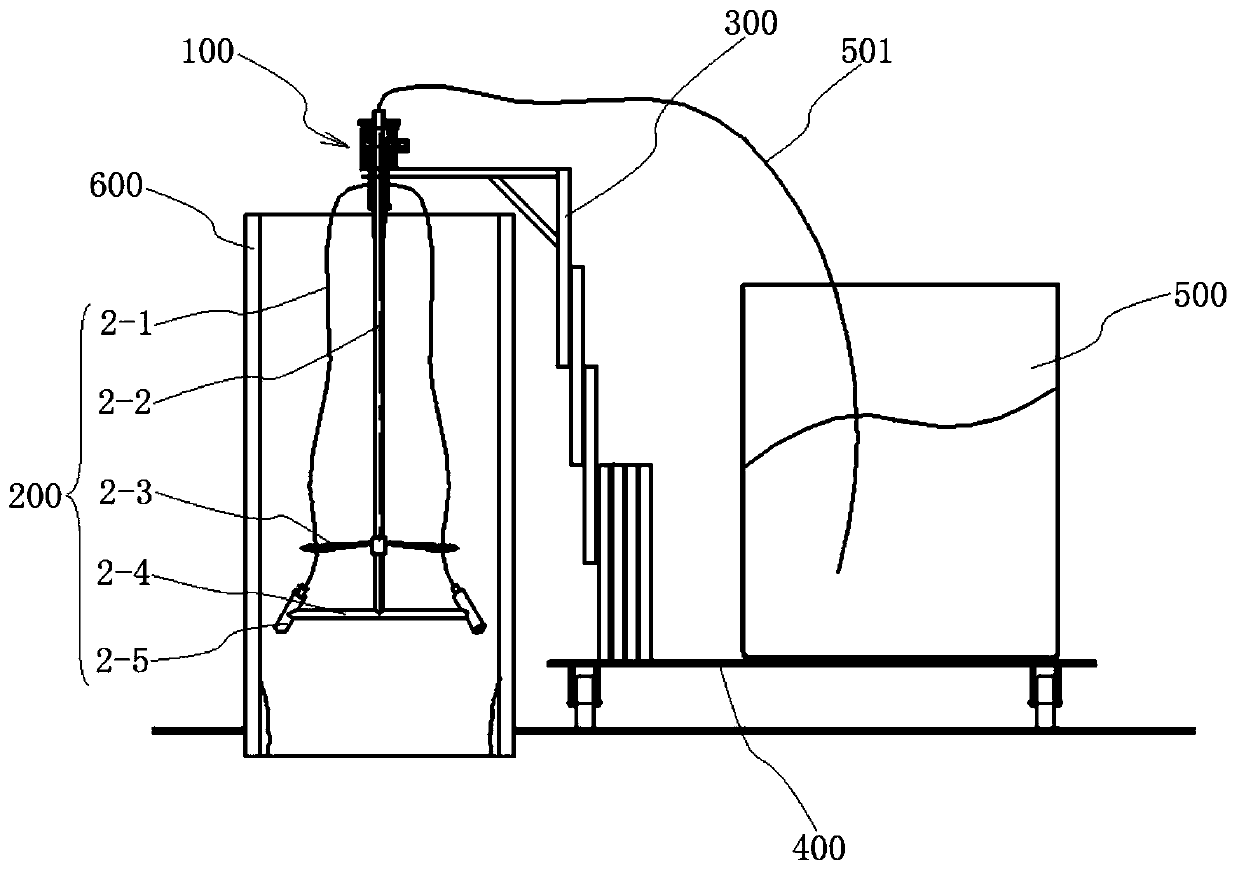

[0040] combine figure 1 and figure 2 As shown, a riser pneumatic purge device in this embodiment includes a rotary seal seat 100, a rotary sandblasting gun 200 and a lifting mechanism 300. The rotary seal seat 100 is used to input mutually independent two-phase fluid media, and has a rotating Function, the rotary sandblasting gun 200 is used to provide rotation drive and negative pressure suction injection of solid particles, the rotary sandblasting gun 200 is installed on the lifting mechanism 300 through the rotating sealing seat 100, and is used to move along the rising pipe 600 under the driving of the lifting mechanism 300 The inner wall lifts and rotates for purging. in,

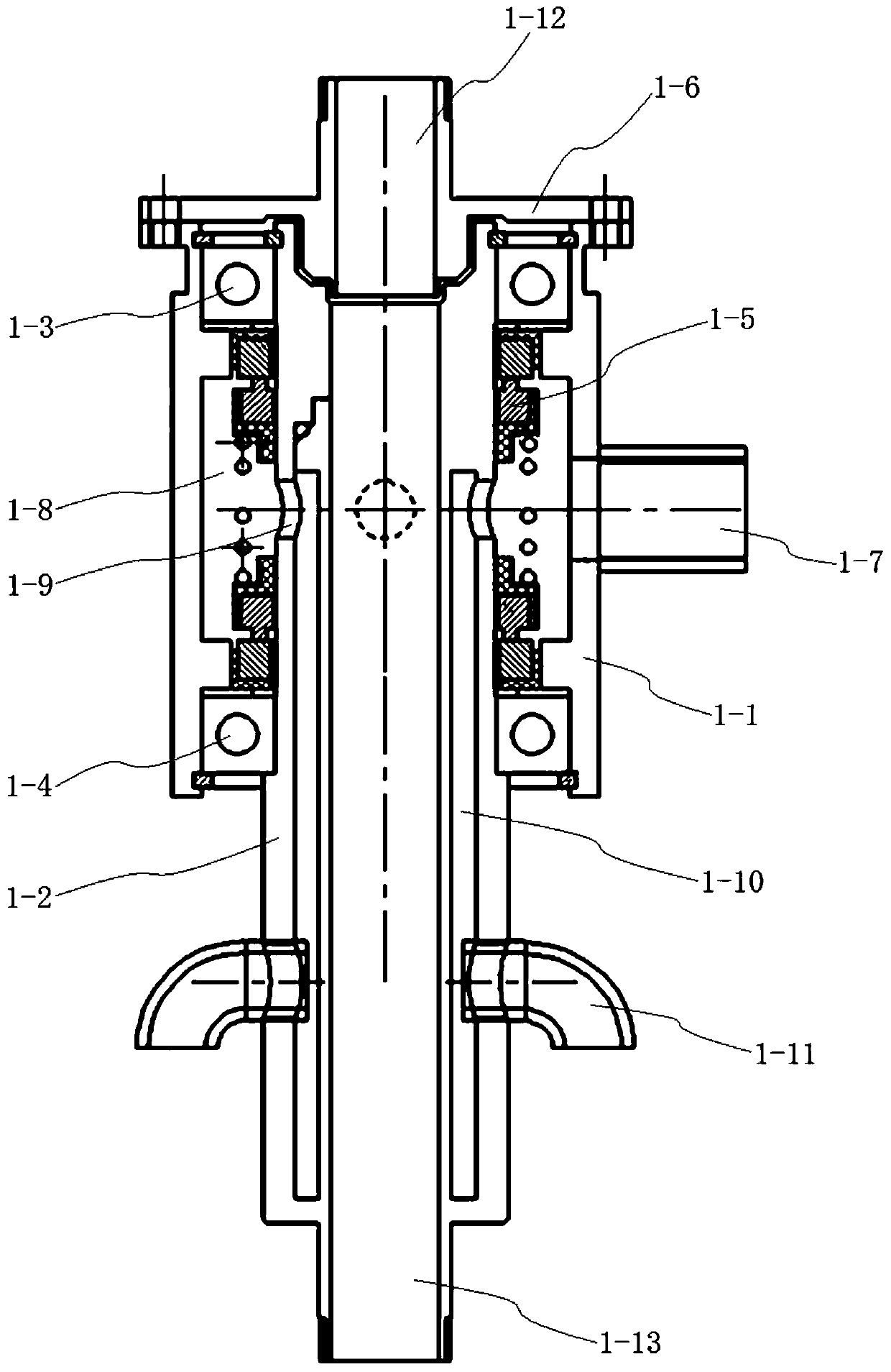

[0041] like figure 2 As shown, the rotary seal seat 100 is a hermetic rotary connector for 360° rotation conveying fluid medium, which includes a static outer cylinder 1-1 and a central axis tube 1-2, and the central axis tube 1-2 is rotatably mounted on a static Inside the outer cylinder 1-1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com