Cable automatic sample preparation detection system

An automatic sample preparation and detection system technology, which is applied in the direction of sampling, measuring devices, and test sample preparation, can solve problems such as inaccurate accuracy, achieve the effects of reducing labor intensity, reducing manual intervention, and simplifying production line design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, which should not be construed as a limitation of the present invention;

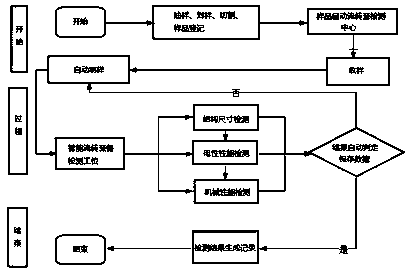

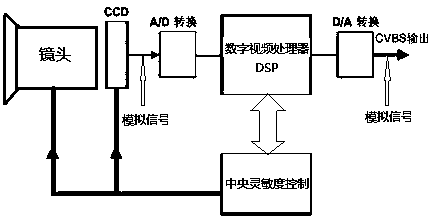

[0022] as attached Figure 1-2 As shown, a cable automatic sample preparation and detection system is connected with a wire and cable sampling support frame, and the sampling support frame assists in identifying the positioning of the cable head, and is connected to the automatic grasping operation mechanism of the sampling support frame, and the automatic grasping operation mechanism Grab and deliver the cable head winding; the fixing device and the cutting device are connected to cut the cable, the fixing device includes a horizontal frame, a baffle fan, an anti-collision baffle, a slide rail and a mechanical claw, and the cutting device is composed of a cutting system, Cutting platform, cutting waste slag and waste material collection hopper, the automatic grabbing ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com