Engineering construction project quality control method and system

A technology for construction projects and engineering projects, applied in the field of quality control methods and systems for engineering construction projects, can solve problems such as inability to directly judge inspection point inspection information and inspection status, poor information integrity and accuracy, and chaotic interweaving of information, etc. Realize visual management, improve work efficiency, and achieve the effect of online management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

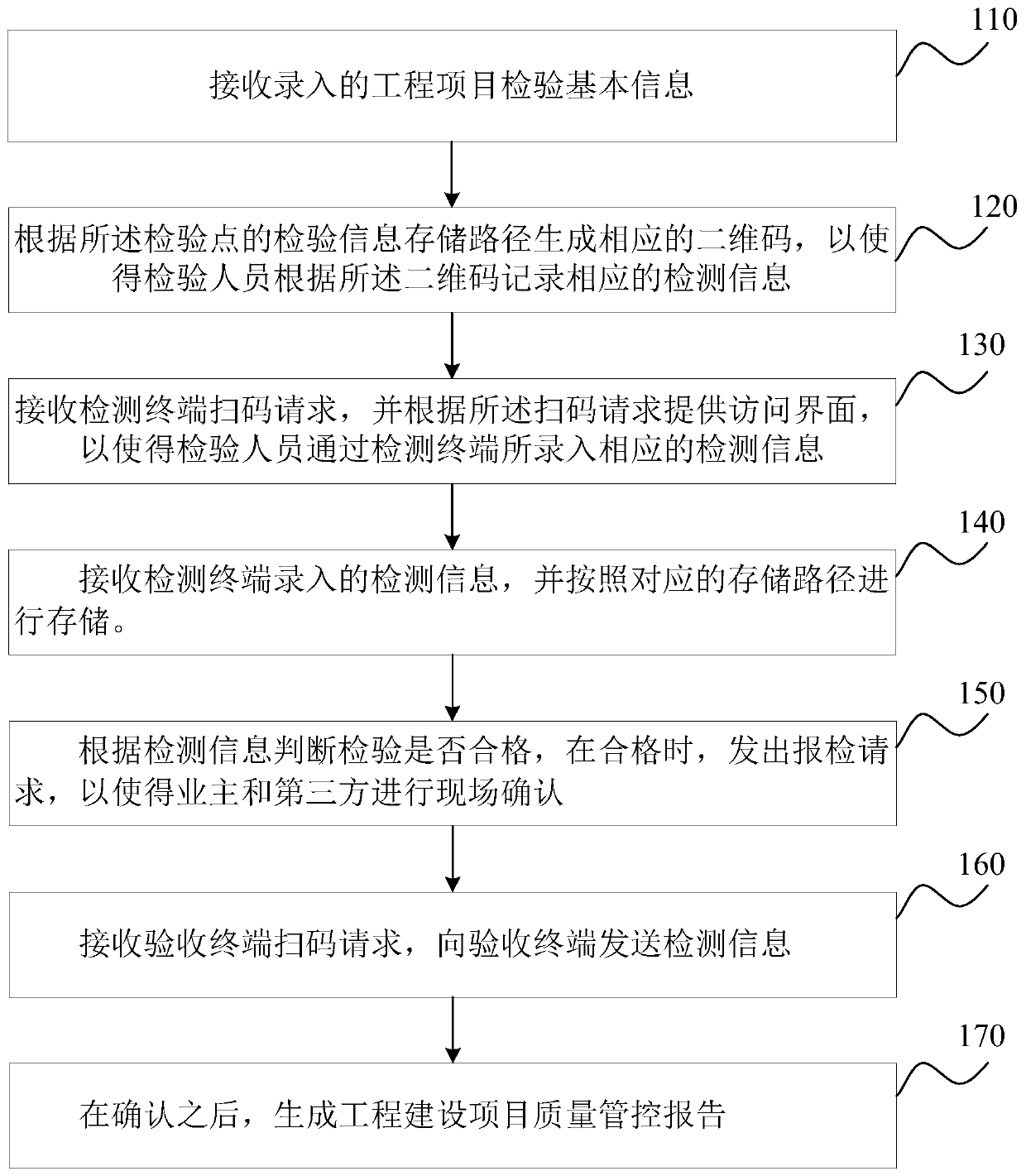

[0076] figure 1 It is a schematic flowchart of a method for quality control of engineering construction projects in Embodiment 1 of the present invention. This embodiment is applicable to the situation of quality control of engineering construction projects. The method can be executed by a quality control device for engineering construction projects and can be integrated in In the server of the engineering construction project quality control system, the following steps are specifically included:

[0077] S110, receiving the basic inspection information of the engineering project entered, the basic inspection information of the engineering project includes: inspection point, inspection point drawing number, welding port number, process, non-destructive testing type and proportion, and the inspection point drawing number includes the additional drawing number and NDT drawing number.

[0078] In the inspection of engineering projects, it is necessary to pre-set multiple inspect...

Embodiment 2

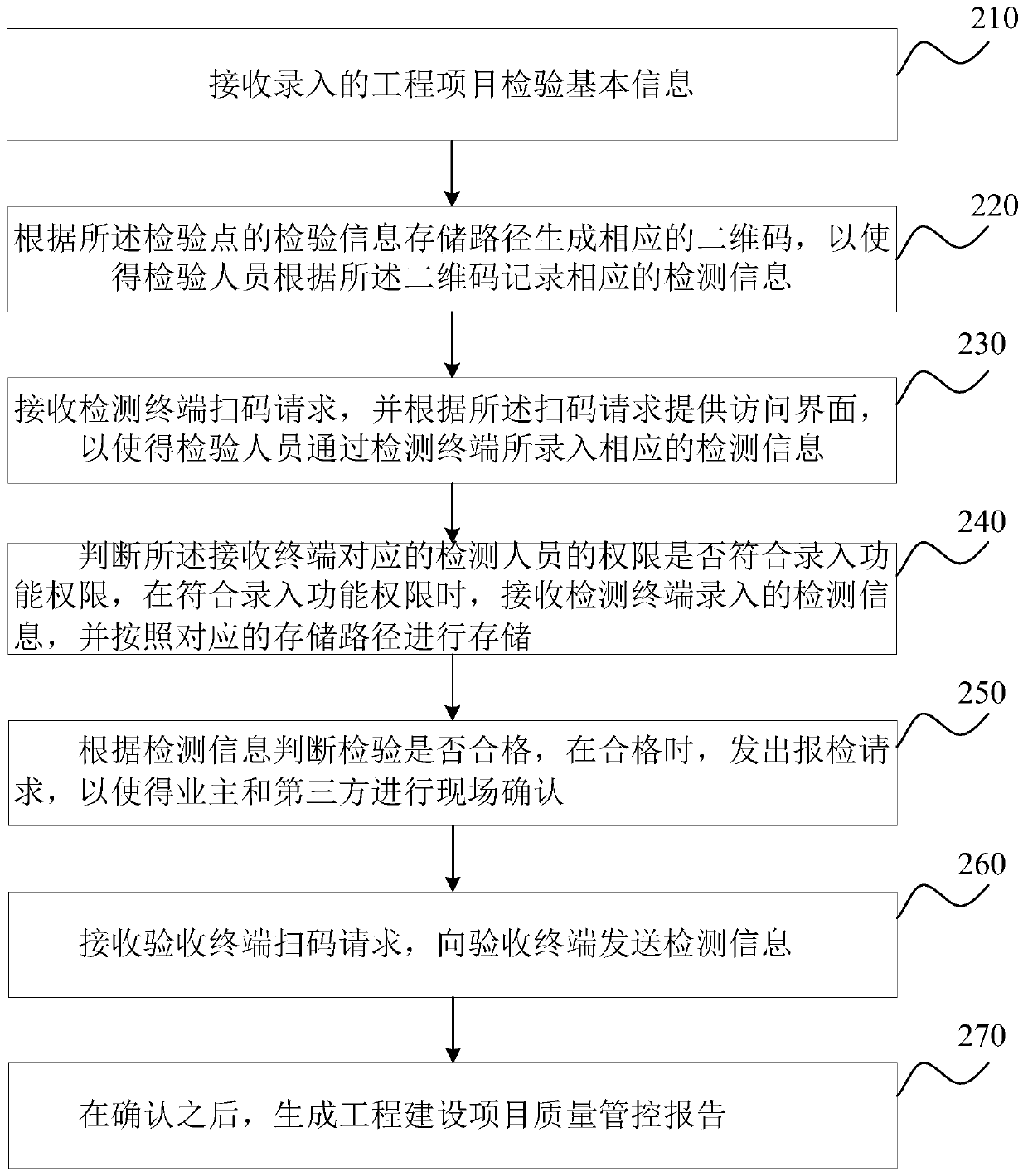

[0096] figure 2It is a schematic flowchart of a method for quality control of an engineering construction project provided in Embodiment 2 of the present invention. This embodiment is optimized on the basis of the above embodiments. In this embodiment, the specific optimization of the detection information entered by the receiving detection terminal is as follows: judging whether the authority of the detection personnel corresponding to the receiving terminal conforms to the entry function authority, and When the entry function authority is met, the detection information entered by the detection terminal is received.

[0097] Correspondingly, the engineering construction project quality control method provided in this embodiment specifically includes:

[0098] S210. Receive the entered basic inspection information of the engineering project. The basic inspection information of the engineering project includes: inspection point, inspection point drawing number, welding port n...

Embodiment 3

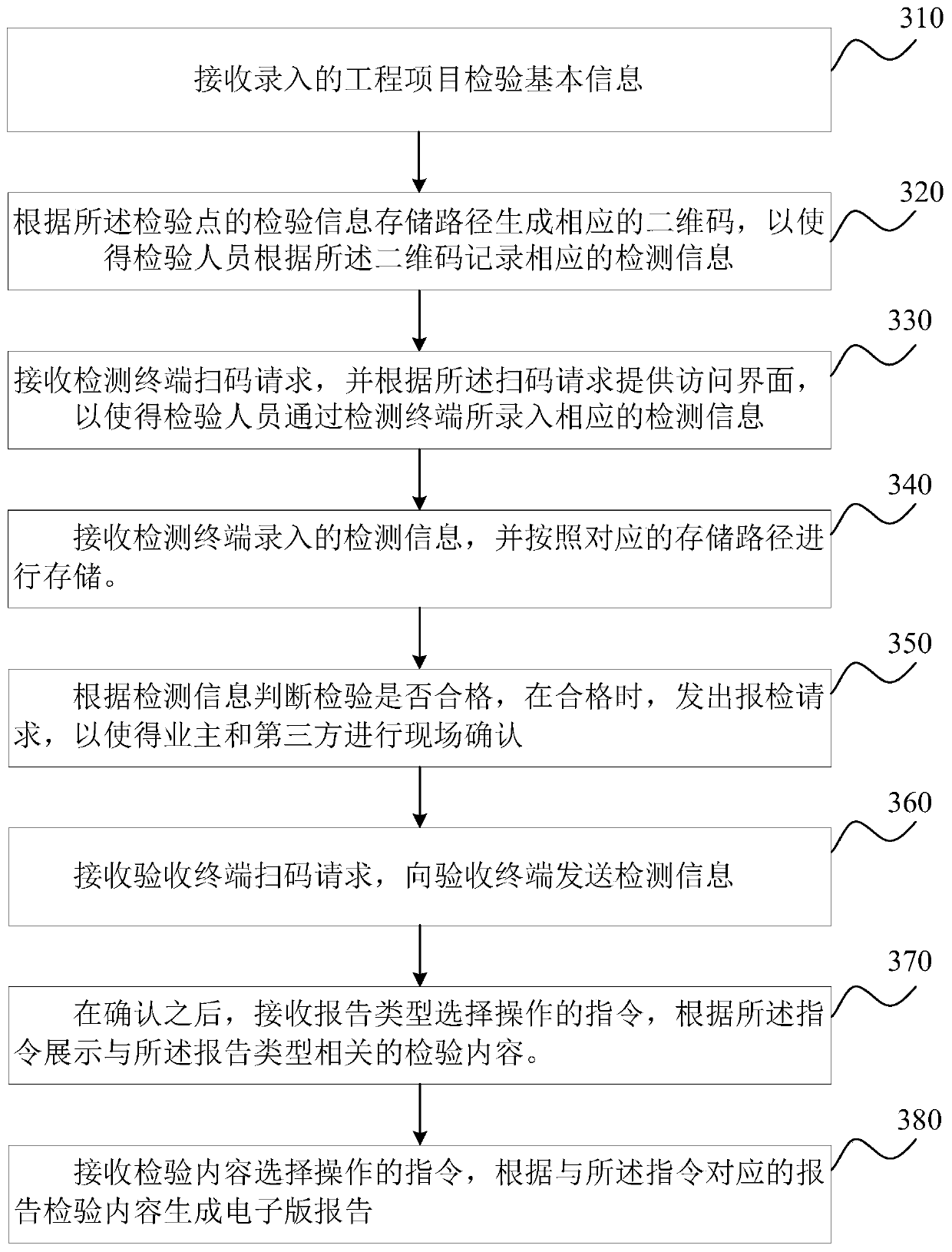

[0110] image 3 It is a schematic flowchart of a method for quality control of an engineering construction project provided by Embodiment 3 of the present invention. This embodiment is optimized on the basis of the above embodiments. In this embodiment, the generation of the construction project quality control report is specifically optimized as follows: receiving the instruction for selecting the report type; displaying the report according to the instruction Type-related inspection content; receiving an instruction for selecting the inspection content, generating an electronic version of the report according to the report inspection content corresponding to the instruction, and implementing online signing.

[0111] Correspondingly, the engineering construction project quality control method provided in this embodiment specifically includes:

[0112] S310, receiving the basic inspection information of the engineering project entered, the basic inspection information of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com