Semiconductor structure and formation method thereof

A semiconductor and channel structure technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as device performance degradation, improve performance, improve heat dissipation performance, and improve self-heating effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

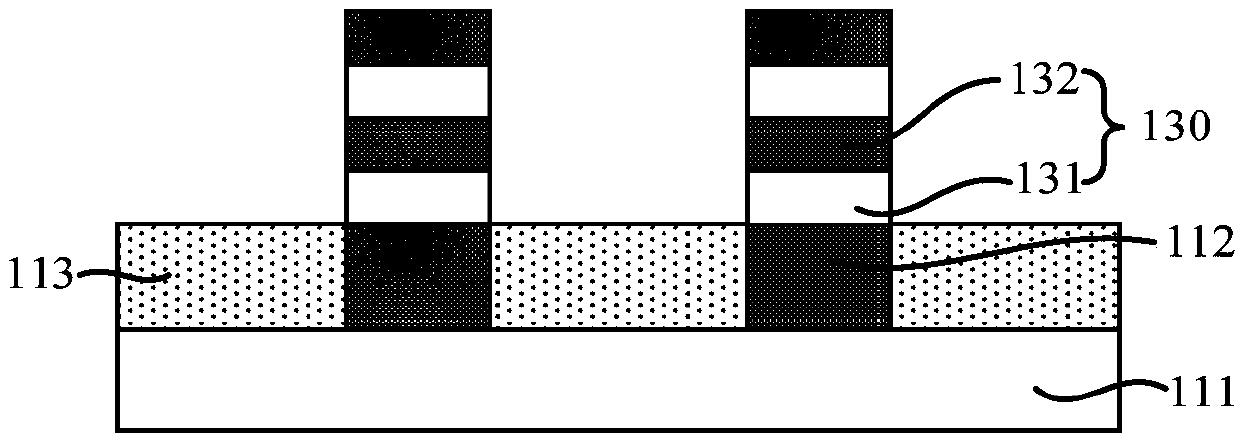

[0014] It can be seen from the background art that the introduction of the SiGe channel technology will easily lead to the degradation of device performance. Analyze the reasons for this:

[0015] Compared with Si, SiGe has a lower thermal conductivity. Therefore, after the introduction of SiGe channel technology, it is easy to cause the heat generated by the device to dissipate too late, thereby reducing the heat dissipation effect of the device.

[0016] Moreover, after the fin structure is introduced into the fully-enclosed gate transistor, compared with the planar transistor, the area occupied by the substrate of the fully-enclosed gate transistor is reduced, the area occupied by the isolation structure is increased, and the area occupied by the substrate is reduced. Small will reduce the heat dissipation effect of the device, and because the material of the isolation structure is usually silicon oxide, the thermal conductivity of silicon oxide is also low, which further d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com