Electromagnetic heating low-power continuous output control circuit

A control circuit, low-power technology, applied in induction heating control, induction heating and other directions, can solve the problem of not being able to fundamentally eliminate noise, increase IGBT loss, etc., to achieve the effect of eliminating electromagnetic noise, low switching loss, and reliable heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

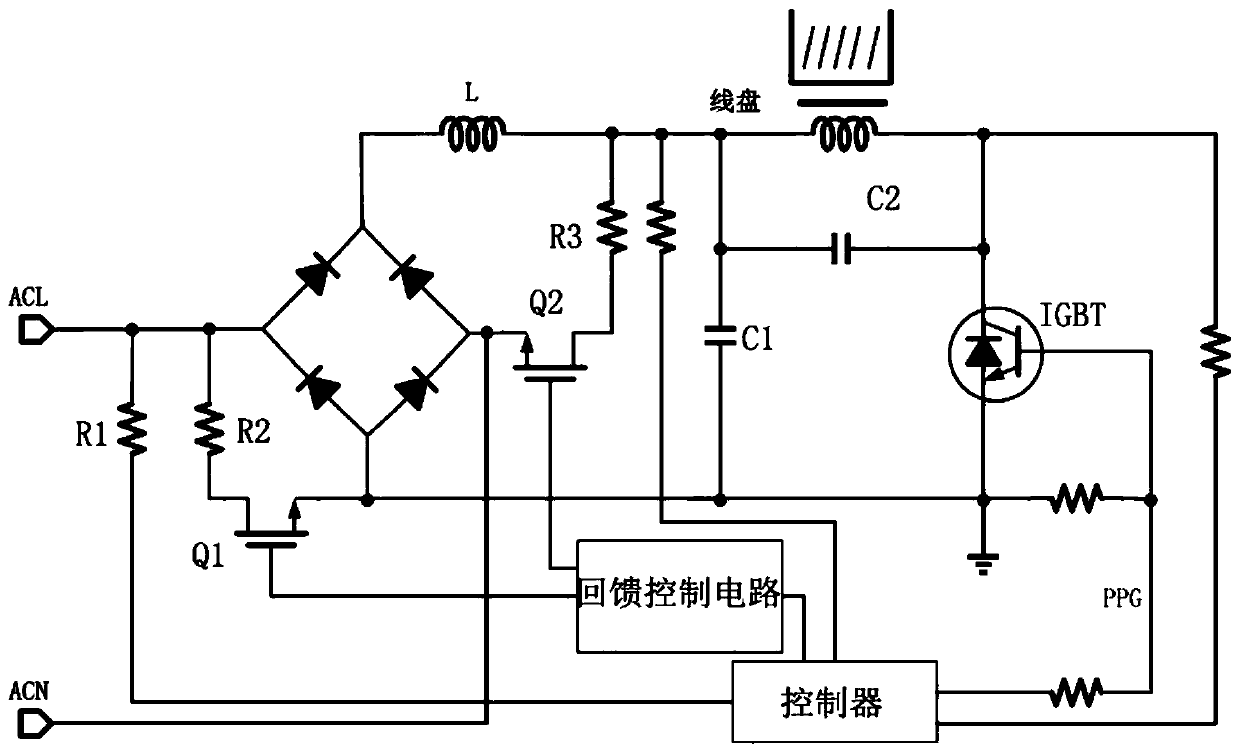

[0019] See attached figure 1 , a control circuit for electromagnetic heating low-power continuous output, including a rectifier bridge, a controller, a heating module, a zero-crossing detection circuit, a feedback circuit, and a feedback control circuit; the rectifier bridge includes a first input terminal connected to an ACL line, connected to The second input end of the ACN line is connected to the first output end of the heating module, and the second output end is connected to the ground; the heating module includes a wire reel, IGBT tubes, capacitors C1 and C2, and one end of the wire reel is connected to the The first output end is grounded through the capacitor C1, and the other end is grounded through the IGBT tube, the capacitor C2 is connected in parallel with the coil, and the IGBT tube is controlled by the controller to realize on-off control; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com