Longitudinal-bending composite ultrasonic vibration degumming method and device based on catenary linear cutter

A composite ultrasonic and tool technology, applied in cleaning methods and utensils, chemical instruments and methods, and fluids using vibration, can solve the problems of difficult cleaning of chemical liquid on the surface of workpieces, rough processing surfaces, and lack of adjustability. The effect of promotion and implementation, high feed accuracy and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

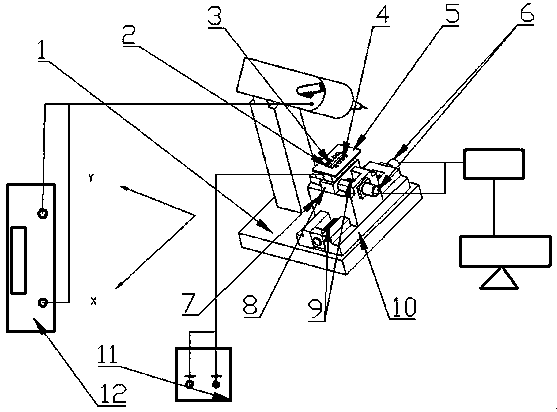

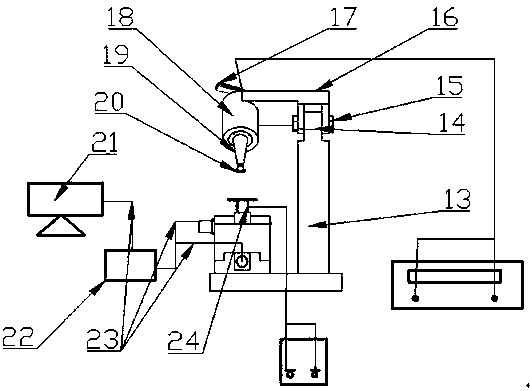

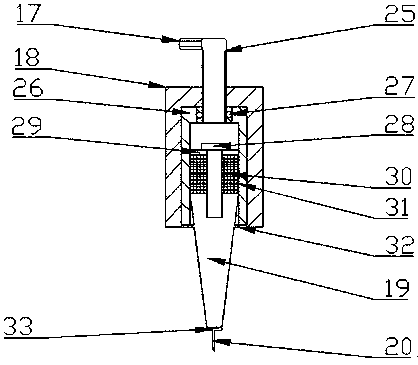

[0031] Example: see figure 1 , figure 2 and image 3 , 1-base plate, 2-plate workpiece, 3-colloid, 4-strip iron sheet, 5-working plate, 6-stepping motor, 7-X-direction slider, 8-Y-direction slider, 9-lead screw , 10-X guide rail, 11-power supply, 12-ultrasonic generator; 13-chuck support column, 14-semi-circular connector, 15-bolt, 16-F-shaped chuck, 17-rotary handle, 18- Outer sleeve, 19-conical horn, 20-catenary cutter, 21-computer, 22-drive board, 23-cable, 24-coil slot; 25-fine-tuning screw, 26-inner sleeve, 27- Bearing, 28-fastening bolt, 29-back cover, 30-piezoelectric ceramic sheet, 31-electrode sheet, 32-flange, 33-horn small end boss.

[0032] The X-direction rail 10 is fixed on the bottom plate 1, and then connected with the X-direction slider 7 through a lead screw 9, and the lead screw 9 is connected with the stepping motor 6, so as to drive the X-direction slider 7 to move on the X-direction rail 10; Then the Y-guided rail and the Y-directed slide block 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com