MBR membrane module root air inlet structure

A technology of air intake structure and membrane module, which is applied in the field of MBR modules, can solve the problems of increasing the difficulty of untangling and casting, loss of aeration effect, and small diameter of aeration holes, so as to reduce the area of aeration dead zone and improve air scrubbing Effect, the effect of good gas scouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

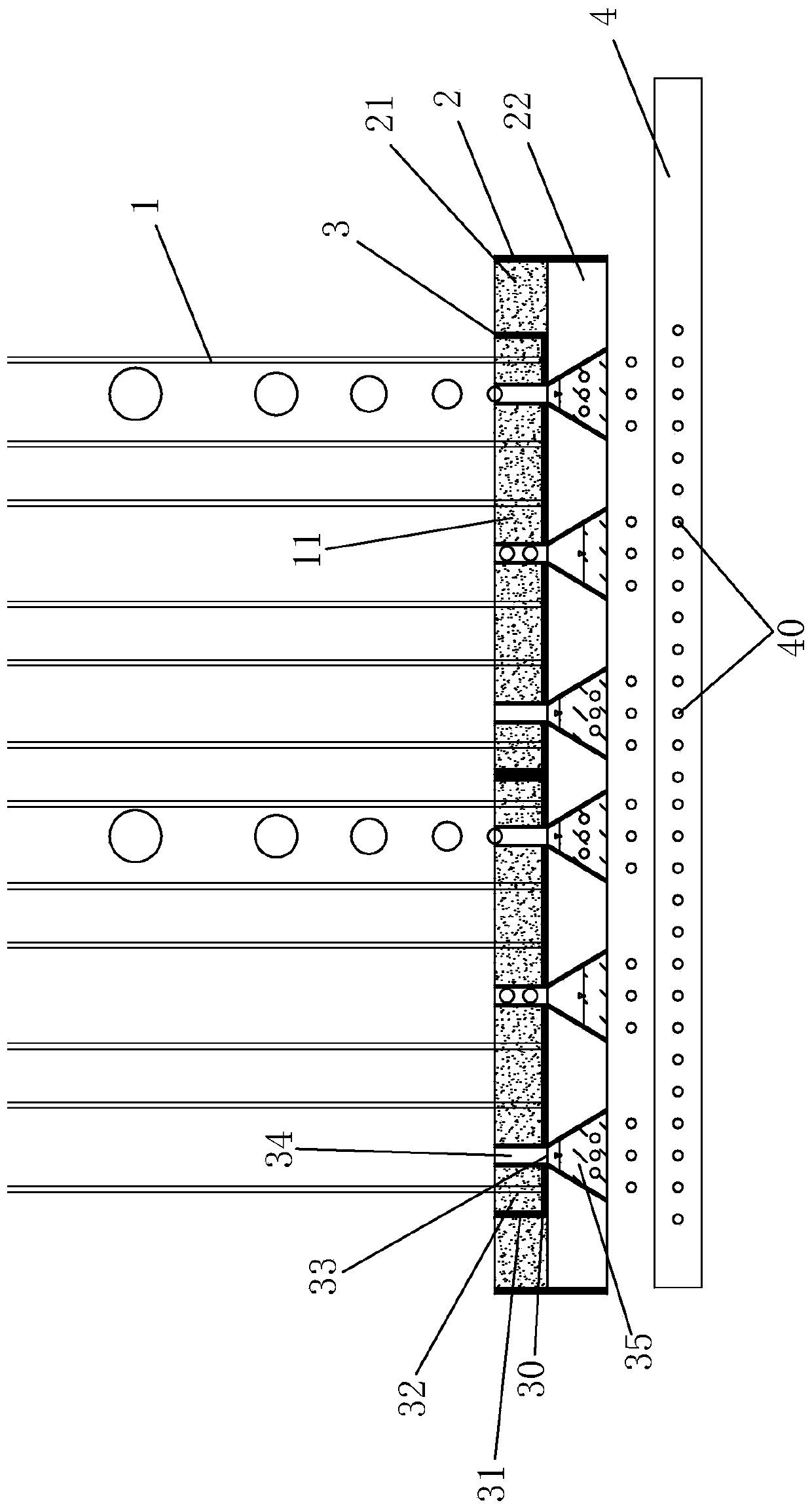

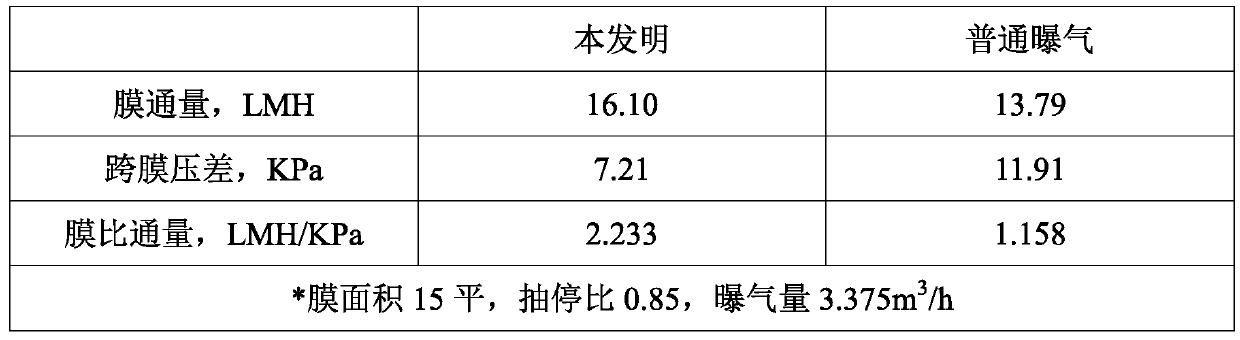

[0046] For a certain domestic sewage, the concentration of activated sludge is 4000-6000mg / L. Fix the curtain-type MBR on the membrane frame, immerse it into the MBR tank, and use the common aeration structure and the membrane module root air intake structure of the present invention to carry out continuous aeration respectively, and perform suction according to the pump-stop ratio of 0.85. Regularly record the membrane flux and transmembrane pressure difference, and run continuously for 6 months.

[0047] Ordinary aeration structure: the curtain-type MBR membrane module adopts the ordinary aeration structure, the membrane area is 15 square meters, and there is no aeration tube at the root, which is a separate aeration; there are two rows of aeration branches on the aeration branch 4, and the aeration direction is obliquely downward The aeration hole 40 with a diameter of 5mm at 45 degrees, the aeration volume of the aeration branch pipe is 3.375m 3 / h, the gas flow rate of t...

Embodiment 2

[0053] For a certain domestic sewage, the concentration of activated sludge is 6000-8000mg / L, the treatment capacity is 600t / d, and the curtain type MBR membrane unit is used with a membrane area of 2400 square meters. The pump-to-stop ratio is 0.8, and the conventional aeration structure and the membrane module root intake structure of the present invention are respectively used for continuous aeration and continuous aeration, and the aeration volume is 600m 3 / h.

[0054] Ordinary aeration structure: the curtain-type MBR membrane module adopts an ordinary aeration structure, and there is no aeration pipe 34 at the root, which is a separate aeration; there are two rows of aeration branch pipes 4 with an aeration direction of 45 degrees downward and a diameter of The aeration hole 40 of 5mm, the aeration volume of the aeration branch pipe 4 is 15m 3 / h, the gas flow rate of the aeration hole 40 is 12m / s.

[0055] The air intake structure at the root of the membrane module ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com