Method for exploiting natural fracture heavy oil reservoir using steam assisted gravity drainage (SAGD) assisted by degradable temporary plugging agent

A technology for natural fractures and heavy oil reservoirs, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc. It can solve the problems of steam injection loss, formation leakage of injection fluid, uneven preheating and fluid communication, etc. Achieve the effects of improving thermal efficiency and economic benefits, shortening the preheating cycle, reducing consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

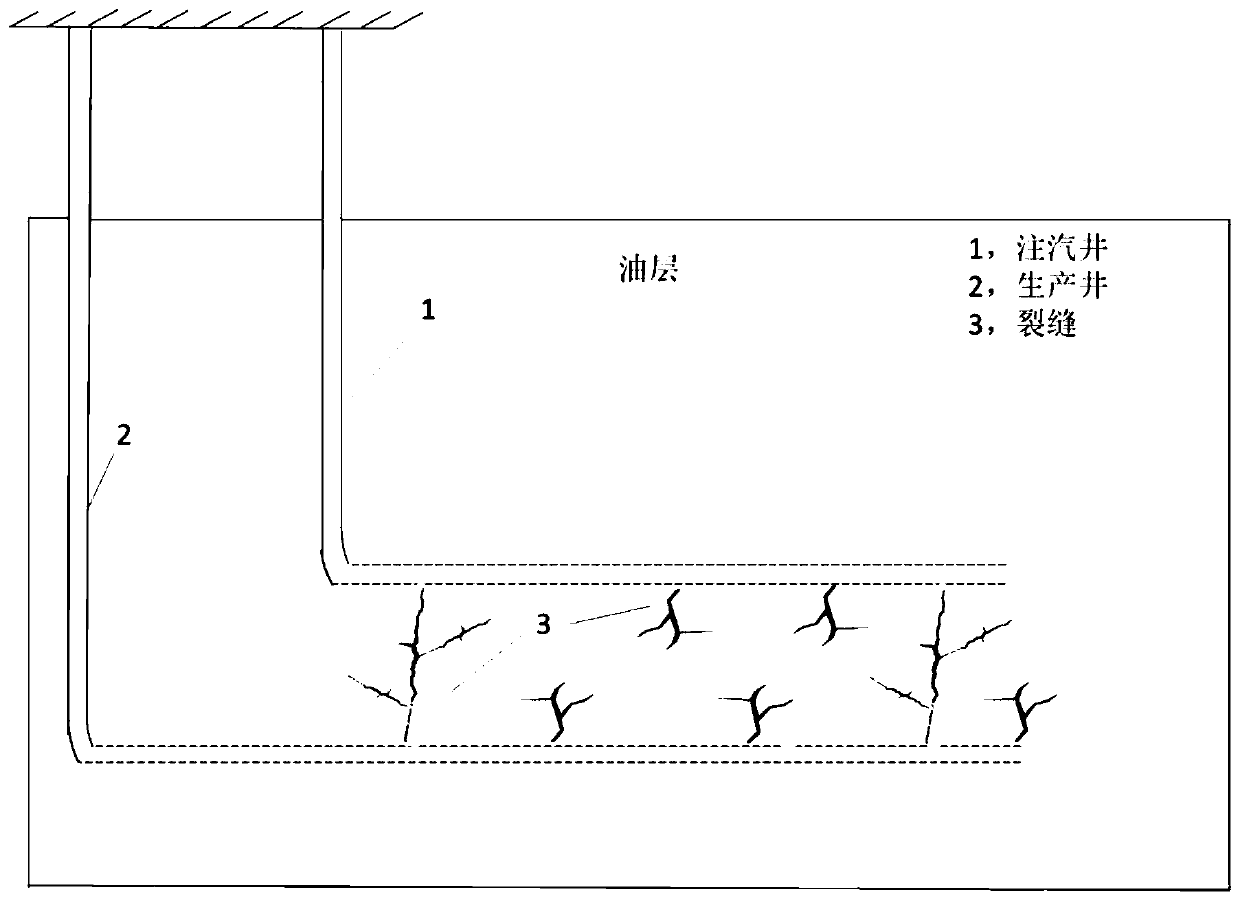

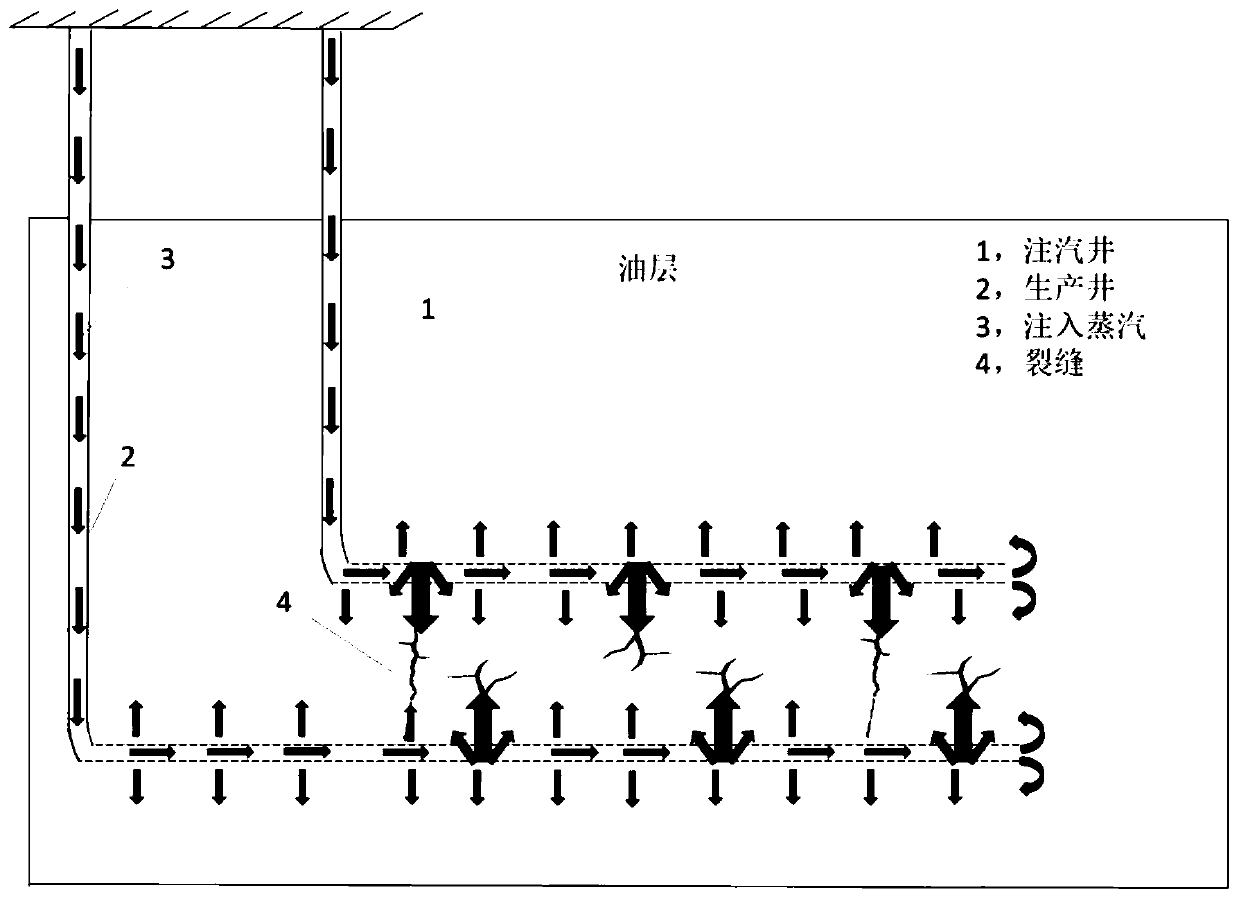

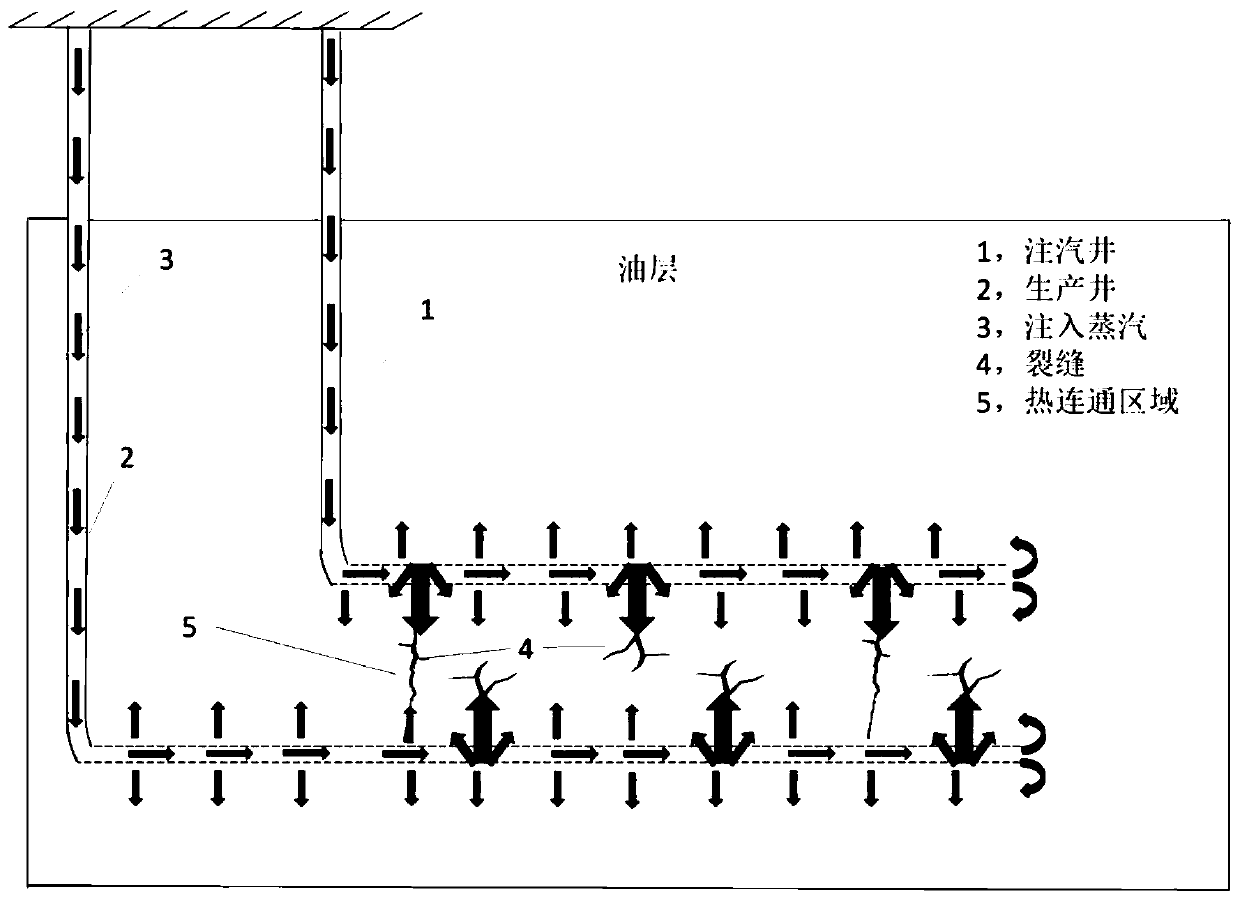

[0025] A kind of method that utilizes degradable temporary plugging agent of the present invention to assist SAGD exploitation natural fracture heavy oil reservoir, comprises the following steps:

[0026] Step S10, such as figure 1 As shown, a certain amount of high-temperature-resistant and degradable temporary plugging agent is injected into the production well and the injection well at the same time, and the temporary plugging agent preferentially enters the natural fractures with better permeability or the connected area of the high-permeability zone, and generates high stress in the natural fractures. Strong gel, so that the subsequent injection of hot water or light oil or the mixture of these two fluids cannot enter the fracture or high permeability area, thereby sealing the fracture;

[0027] The injection volume of the above-mentioned temporary plugging agent can be determined according to the length of the horizontal well and the degree of development of natural fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com