Method and device for preventing sand settling in fracturing pump truck hydraulic end suction manifold

A technology for fracturing pump trucks and suction pipes, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as increasing labor intensity of personnel, so as to avoid or reduce sand settling and reduce labor costs. Strength, safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below.

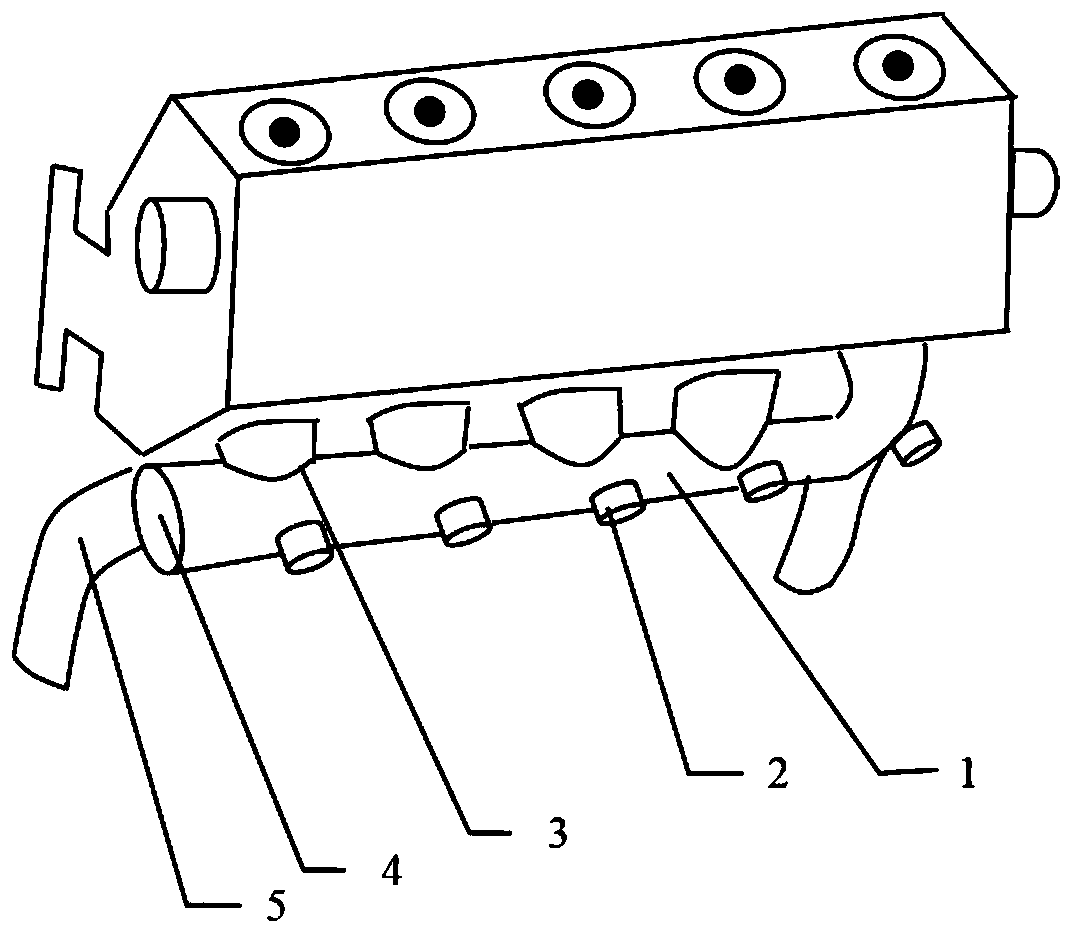

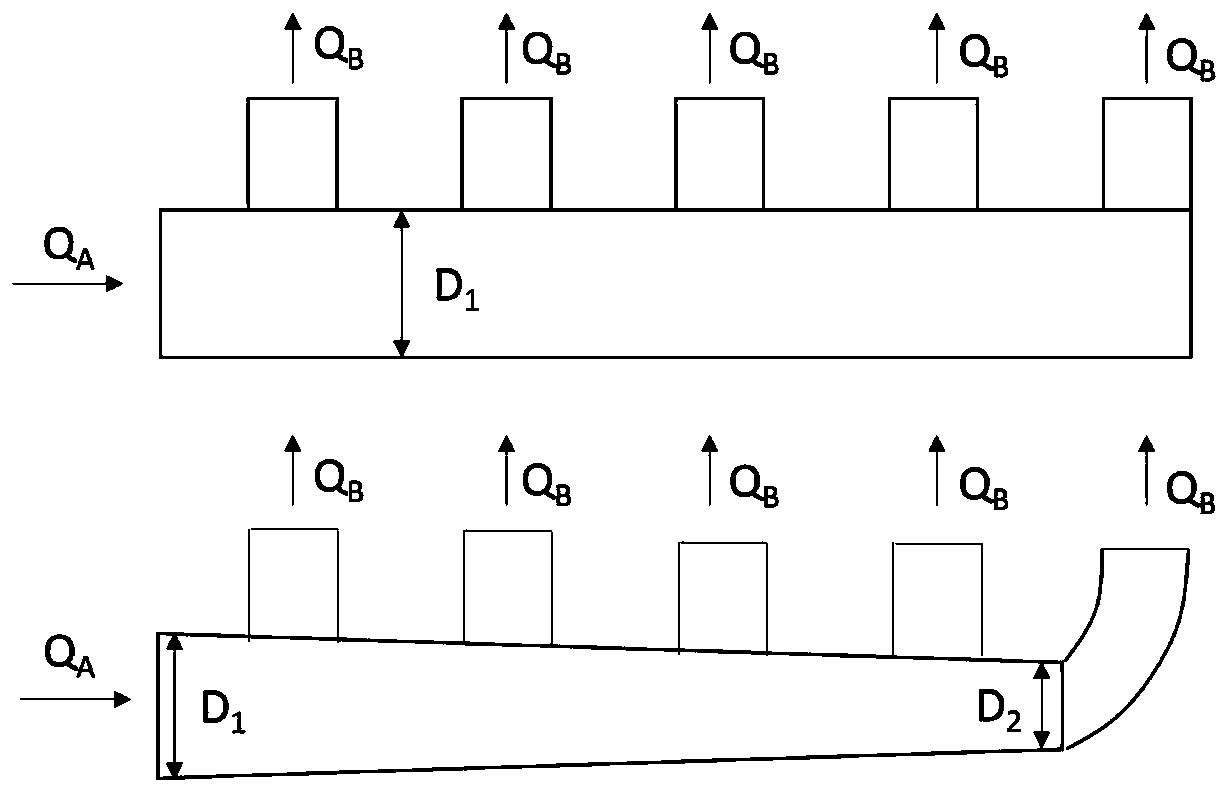

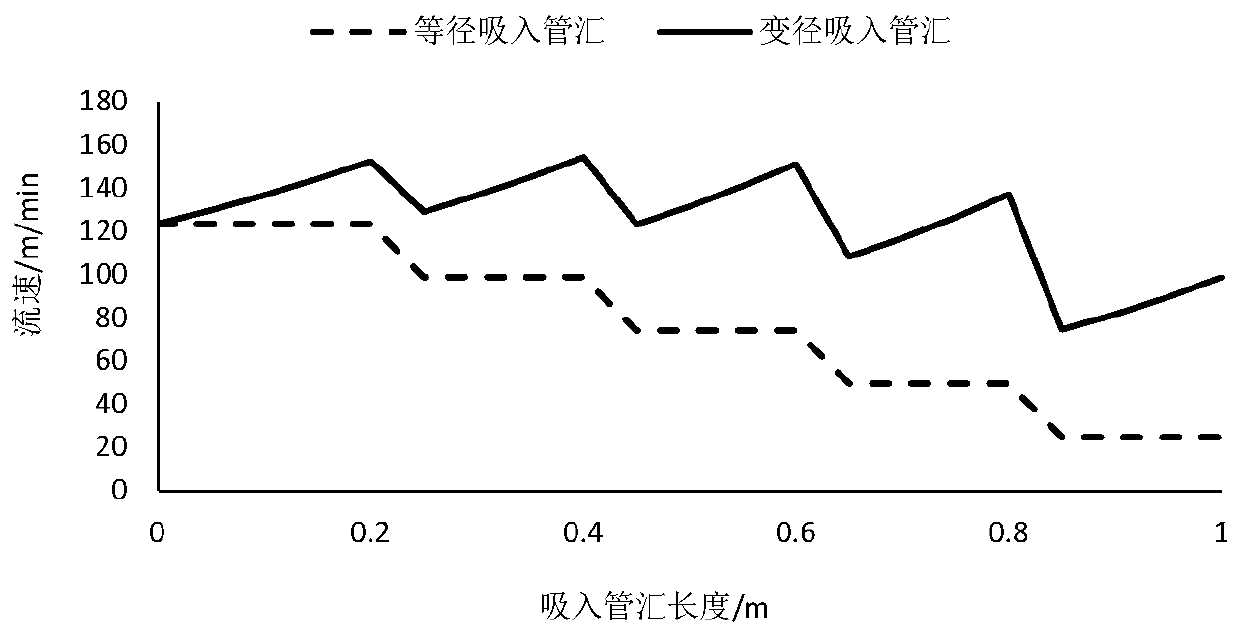

[0027] A method for preventing sand settling in the suction manifold of the hydraulic end of the fracturing pump truck. The suction manifold adopts a variable-diameter pipe, and determining the shape of the variable-diameter pipe includes the following steps:

[0028] (1) Determine the length L of the suction pipe and the diameter D of the suction port of the suction manifold 吸入口 and the fracturing fluid flow rate Q at the outlet 排出口 . Suction pipe length L and suction port diameter D of suction manifold 吸入口 Determined according to other components of the hydraulic end of the fracturing pump truck, the fracturing fluid flow rate Q at the outlet 排出口 Determined according to construction needs.

[0029] (2) Determine the critical settling velocity v of fracturing sand in fracturing fluid through settling experiments 沉降 .

[0030] (3) Using the formula Calculate the critical diameter D of the suction manifold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com