A method to solve the problem of high local hardness of cast iron castings after welding repair

A technology with high hardness and welding repair, which is applied to welding equipment, arc welding equipment, furnaces, etc., can solve the problems of increased cleaning difficulty, high equipment investment and operation and maintenance costs, and high local hardness, so as to save equipment investment and operating electricity costs , Improve work efficiency and economic benefits, reduce the effect of organizational formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

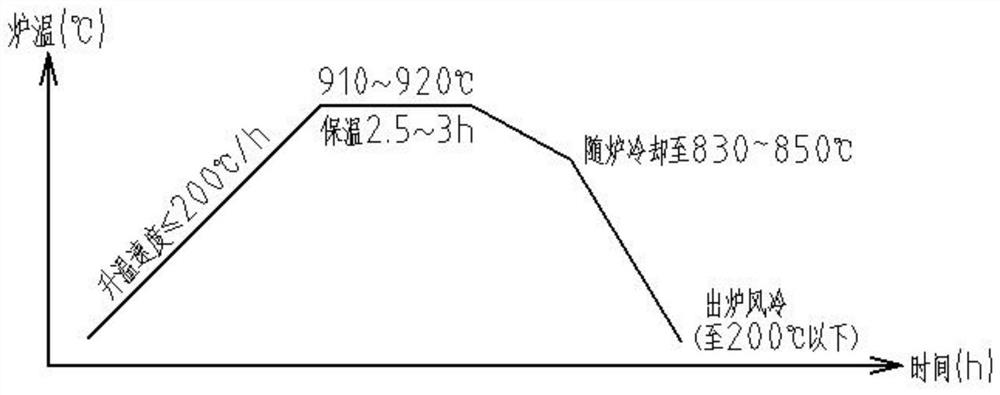

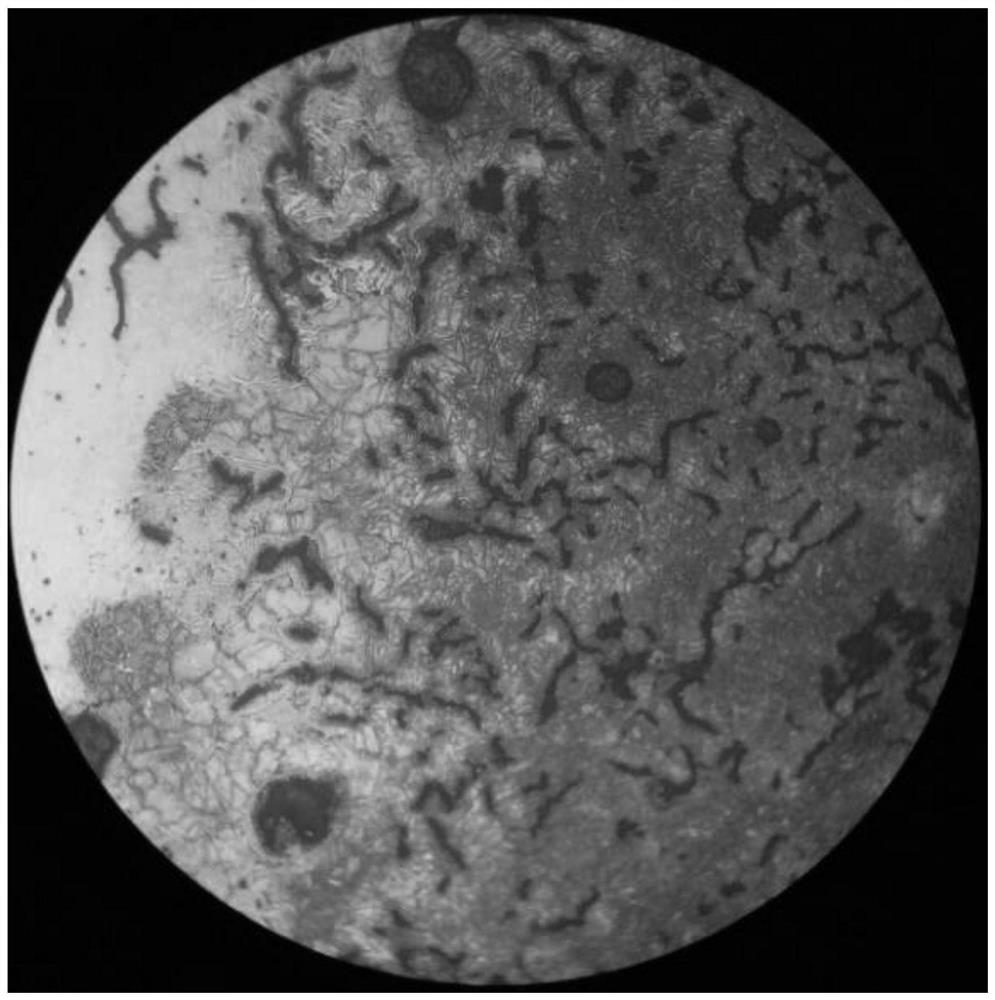

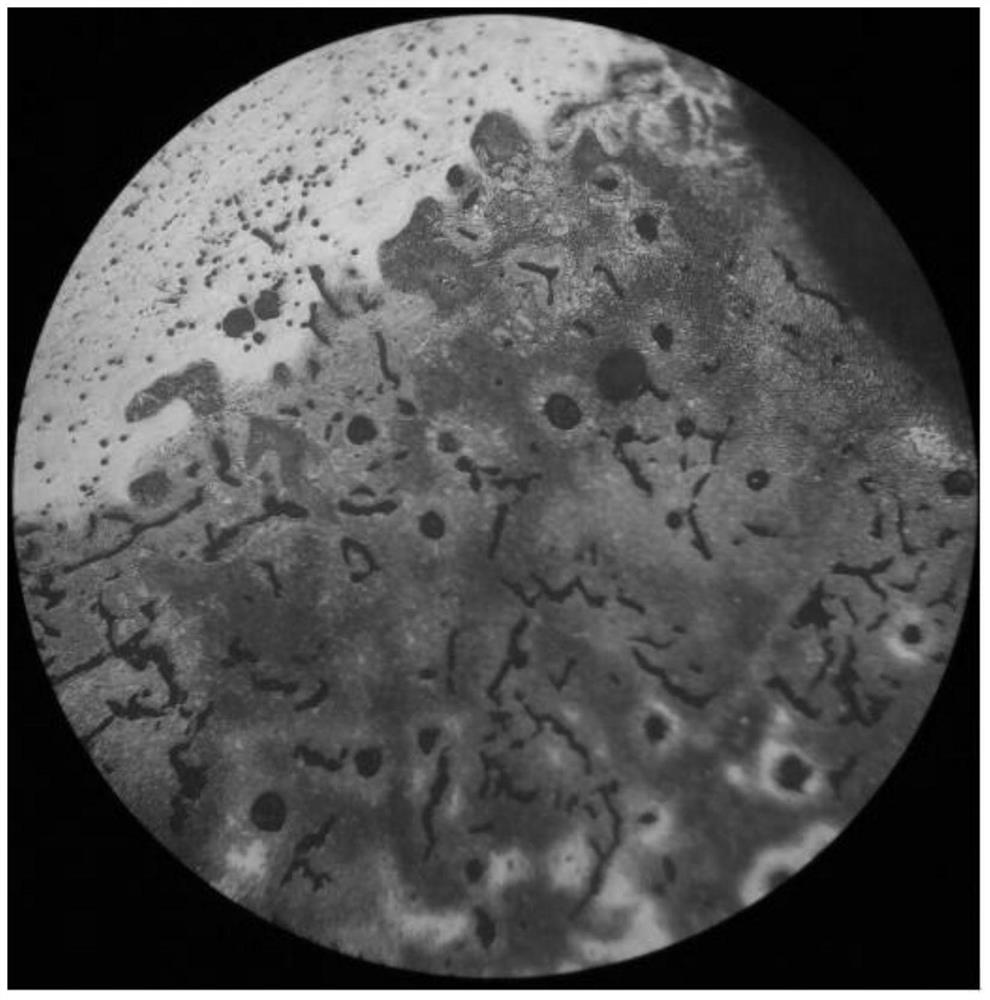

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method to solve the problem of high local hardness of cast iron castings after welding repair. The welding repair current is set to 80A, and the intermittent welding repair method is adopted. Knock off the welding slag before the next intermittent welding. After the welding repair is completed, the welding slag should be cleaned up, and the surface must be polished to restore the appearance of the casting. The castings after welding repair are tempered in a box-type annealing furnace. The tempering temperature rise rate is 30-150°C / h, the holding temperature is 450°C, and the holding time is 2 hours. The welding repair of the castings is inspected before and after welding The hardness of the site and the normal site, the results are attached in Table 1.

Embodiment 2

[0030] This embodiment provides a method to solve the problem of high local hardness of cast iron castings after welding repair. The welding repair current is set to 110A, and the intermittent welding repair method is adopted. Knock off the welding slag before the next intermittent welding. After the welding repair is completed, the welding slag should be cleaned up, and the surface must be polished to restore the appearance of the casting. The castings after welding repair are processed together with the stress relief castings in the stress relief annealing furnace, and the tempering heat treatment is carried out using the heating conditions of stress relief annealing. The temperature rise rate is 30-150°C / h, and the holding temperature is 580°C. For 2 hours, test the hardness of the welding repaired part and the normal part of the casting before and after the welding repair, and the results are attached in Table 1.

Embodiment 3

[0032] This embodiment provides a method for solving the problem of high local hardness of cast iron castings after welding repair. The welding repair current is set to 100A, and the intermittent welding repair method is adopted. Knock off the welding slag before the next intermittent welding. After the welding repair is completed, the welding slag should be cleaned up, and the surface must be polished to restore the appearance of the casting. The castings after welding repair are processed together with the stress relief castings in the stress relief annealing furnace, and the tempering heat treatment is carried out using the heating conditions of stress relief annealing. The temperature rise rate is 30-150°C / h, and the holding temperature is 580°C. For 2 hours, test the hardness of the welding repaired part and the normal part of the casting before and after the welding repair, and the results are attached in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com