Magnesium alloy phosphating method and pickling solution thereof

A magnesium alloy and pickling technology, which is applied in the coating process of metal materials, etc., can solve the problems of local blackening, floating dust on the surface of magnesium alloy workpieces, uneven color of phosphating film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

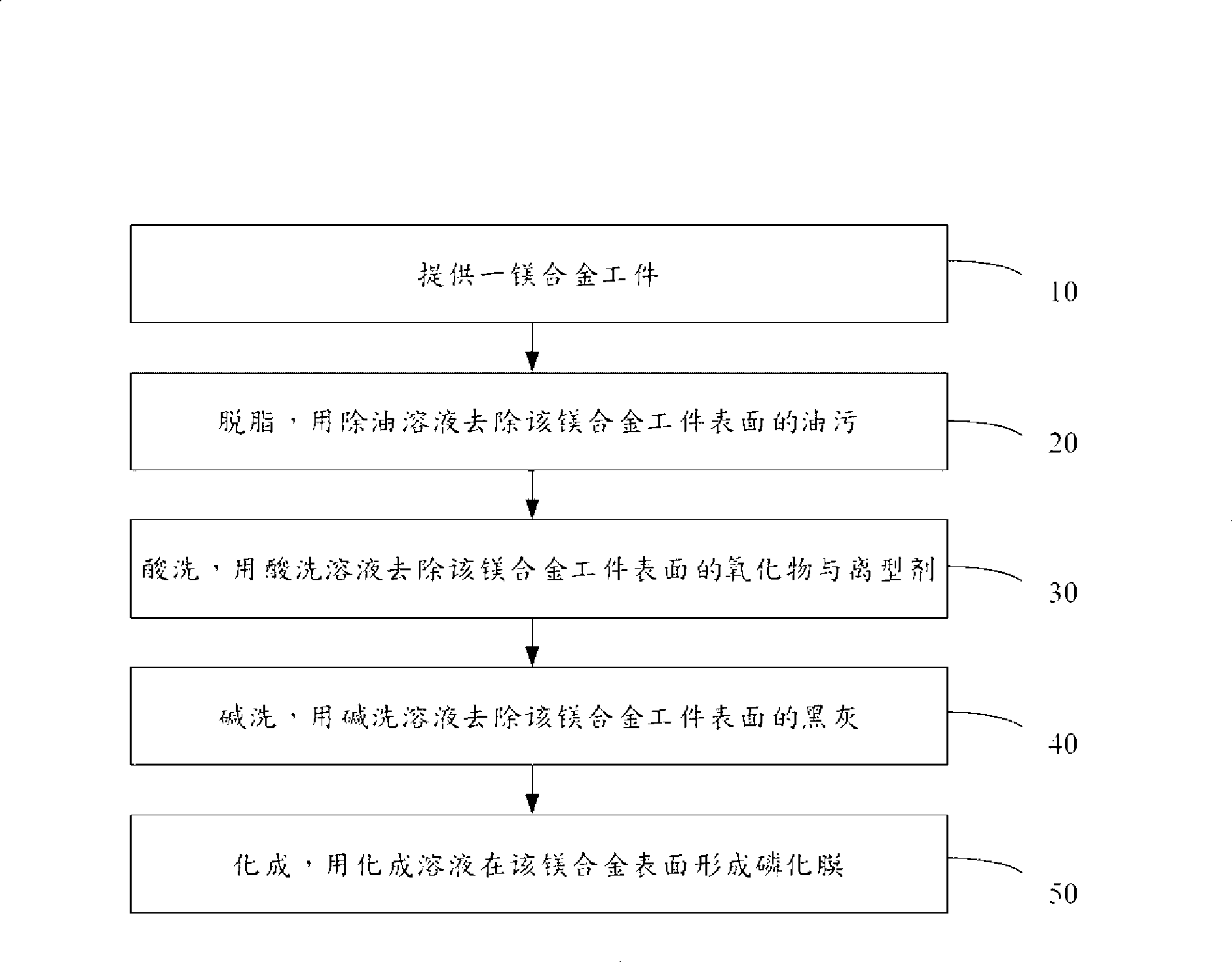

[0012] The magnesium alloy phosphating method of the present invention will be further described in detail with reference to the accompanying drawings and examples.

[0013] See figure 1 , is shown as the flow chart of the magnesium alloy phosphating method of preferred embodiment of the present invention, and it comprises the following steps:

[0014] Step 10, providing a magnesium alloy workpiece;

[0015] Step 20, degreasing, using a degreasing solution to remove the oil on the surface of the magnesium alloy workpiece;

[0016] Step 30, pickling, using a pickling solution to remove oxides and release agents on the surface of the magnesium alloy workpiece;

[0017] Step 40, alkali washing, using an alkali washing solution to remove the black ash on the surface of the magnesium alloy workpiece;

[0018] Step 50, chemical formation, using a chemical formation solution to form a phosphating film on the surface of the magnesium alloy.

[0019] In step 20, the degreasing time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com