Submersible double suction electric pump

A submersible motor and electric pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of submersible pump cavitation, motor heating, easy to sink to the bottom of the bottom of the water, etc., to prevent cavitation and prevent particle precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

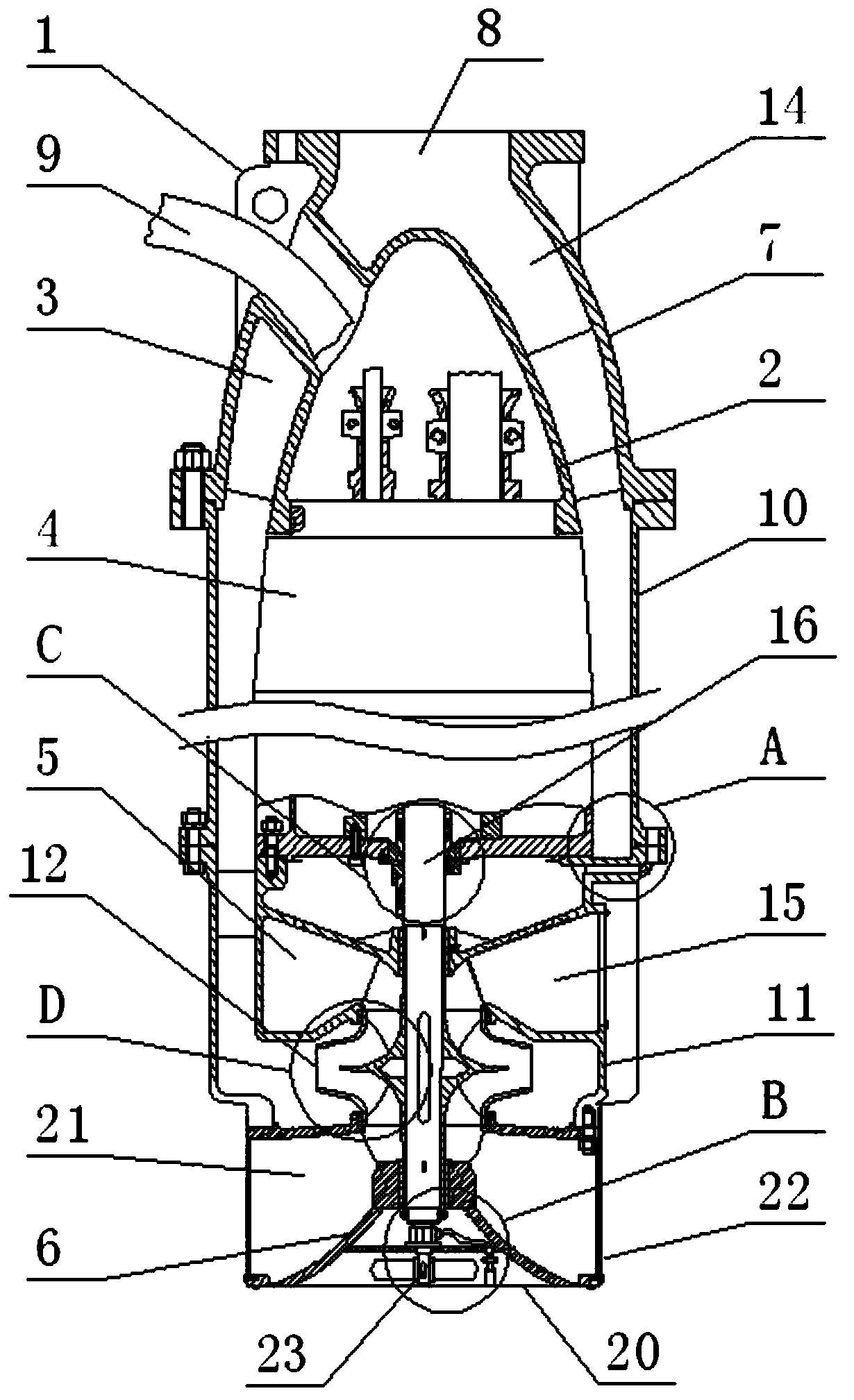

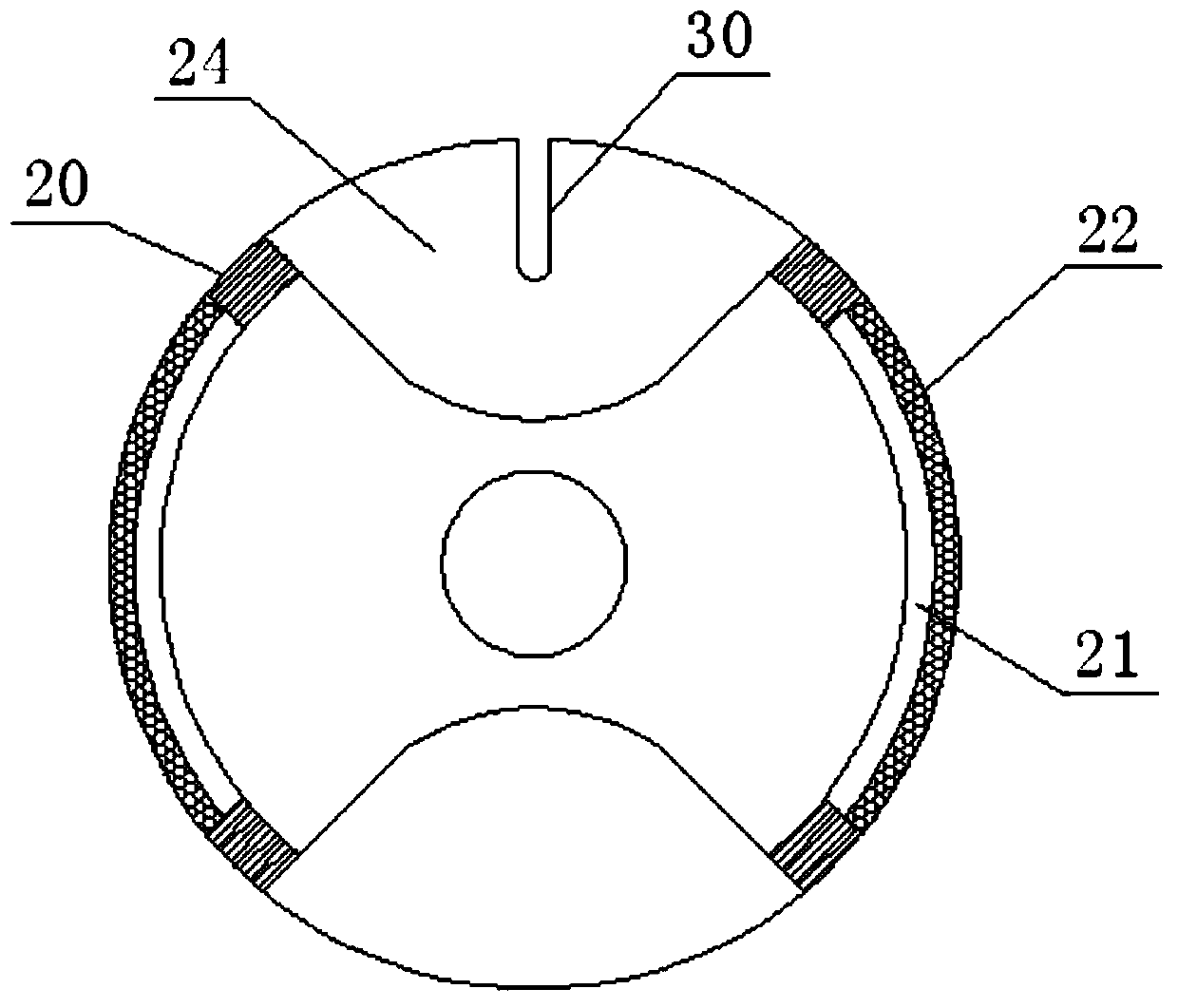

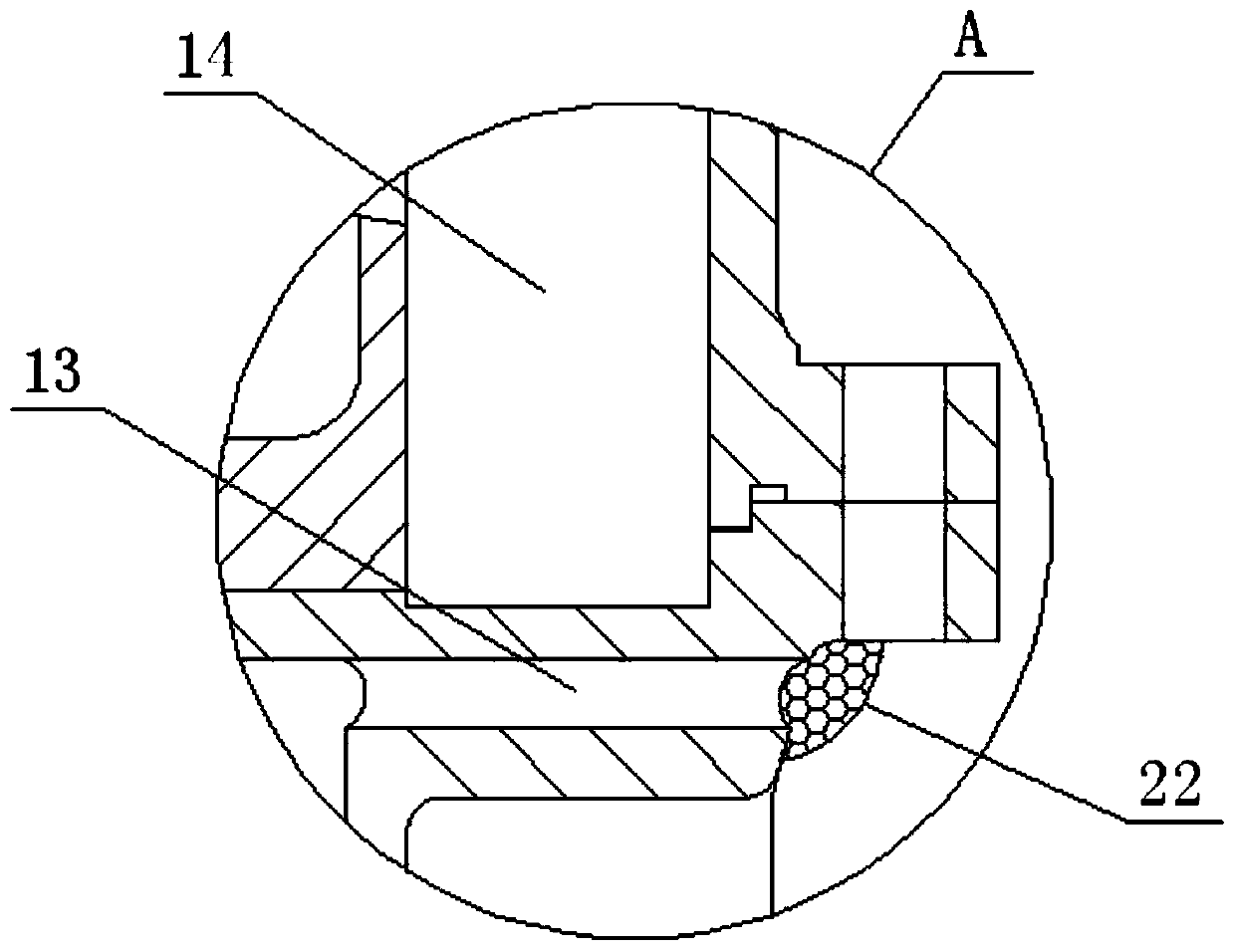

[0027] according to Figure 1-6 A submersible double-suction electric pump shown includes an integral casing 1 and a submersible motor 2, the submersible motor 2 adopts a wet submersible motor, and the integral casing 1 sequentially includes a water outlet section 3 and a motor section from top to bottom 4. The working part section 5 and the water absorption section 6, the submersible motor 2 is located inside the water outlet section 3 and the motor section 4, and the water outlet section 3 includes a water outlet shell 7, and the top of the water outlet shell 7 is provided with a drain port 8, One side of the water outlet shell 7 is provided with a first cable 9, the first cable 9 is connected to the electric wire of the submersible motor 2, the motor section 4 and the working part section 5 are provided with the same water cover 10, and the working part section 5 includes a volute 11 and a double-suction impeller 12, the volute 11 has an exhaust hole 13 on one side, and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap