Composite temperature equalization plate and manufacturing method thereof

A manufacturing method and vapor chamber technology, applied in the field of heat dissipation, can solve problems such as broken powder sintered structure, affecting capillary conduction capacity, complex sealing operation, etc., to achieve the effect of ensuring stable work, increasing capillary conduction capacity, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

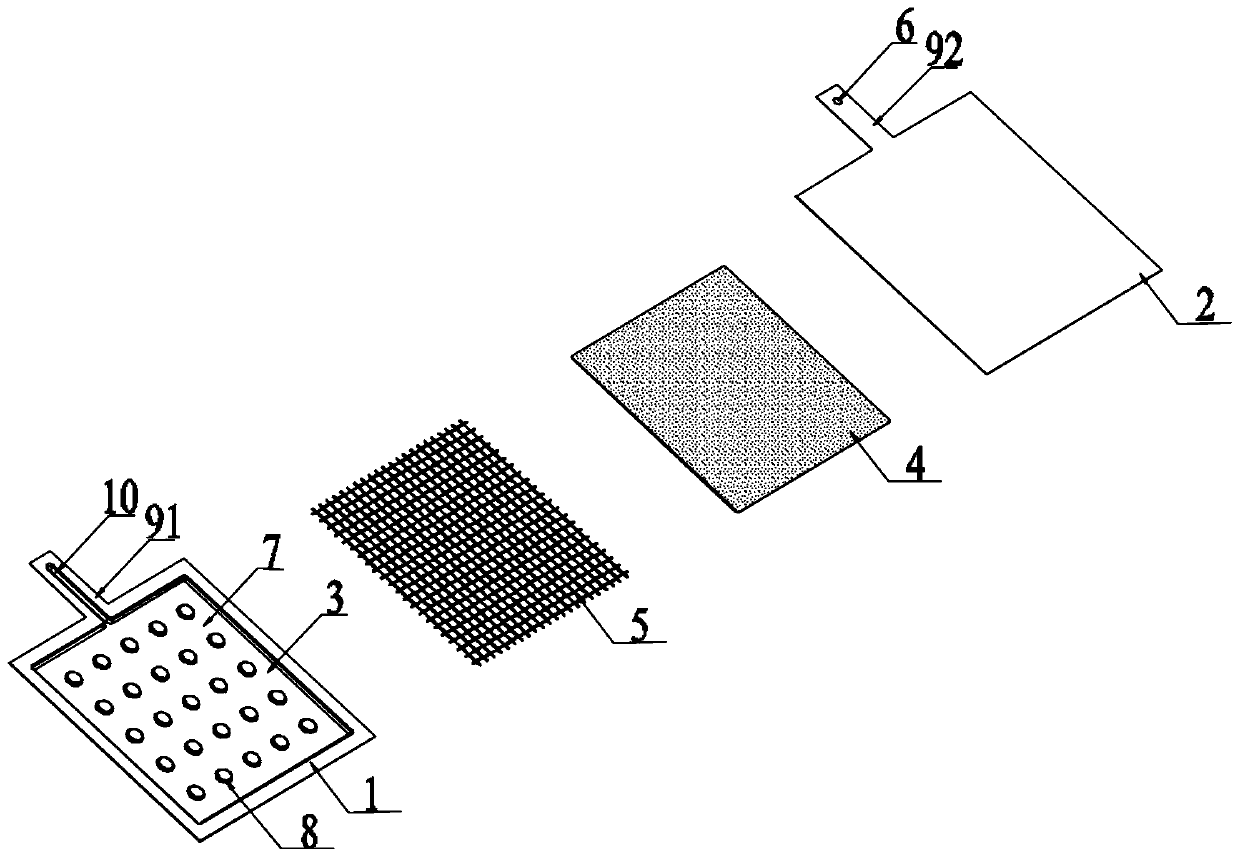

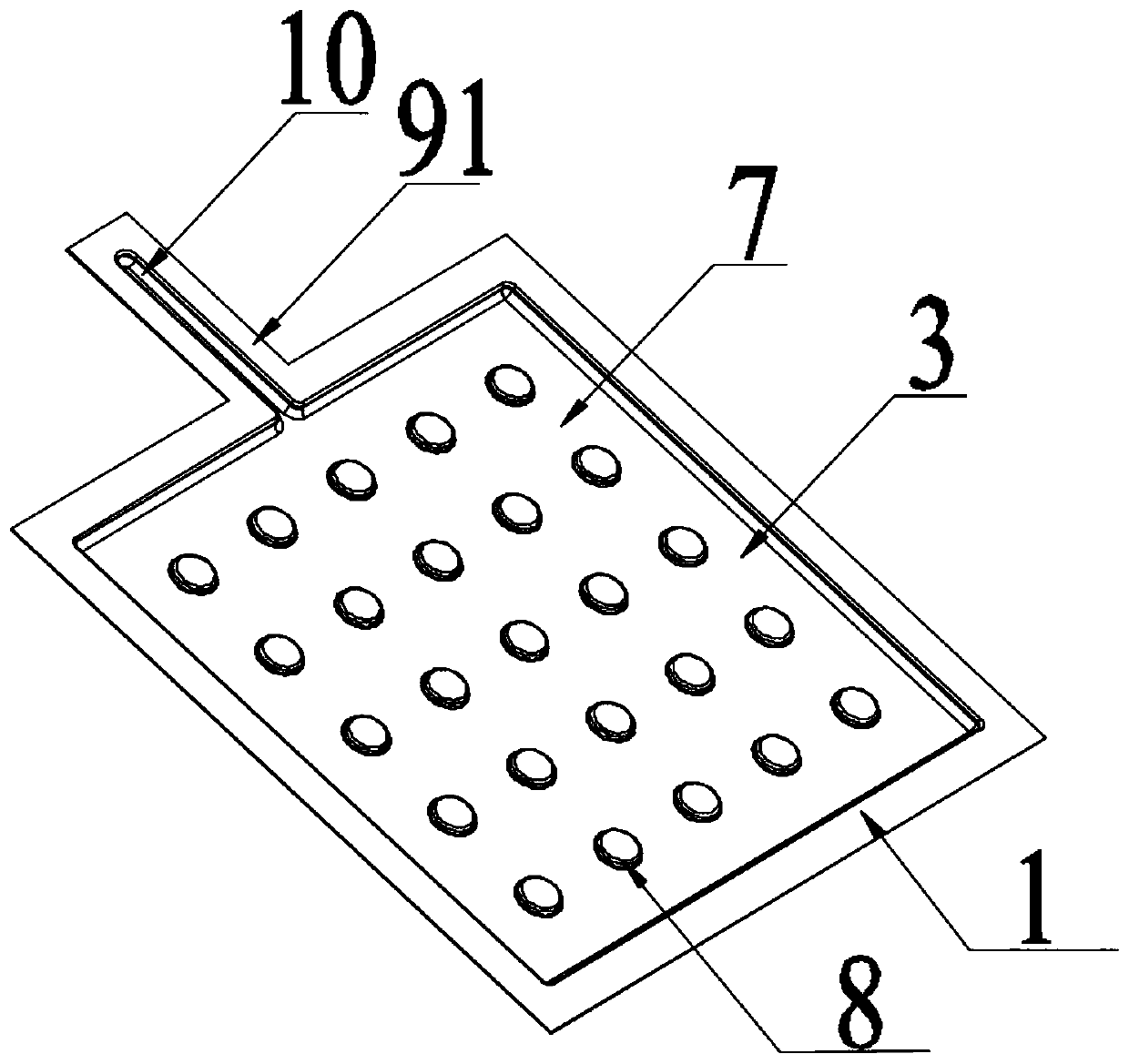

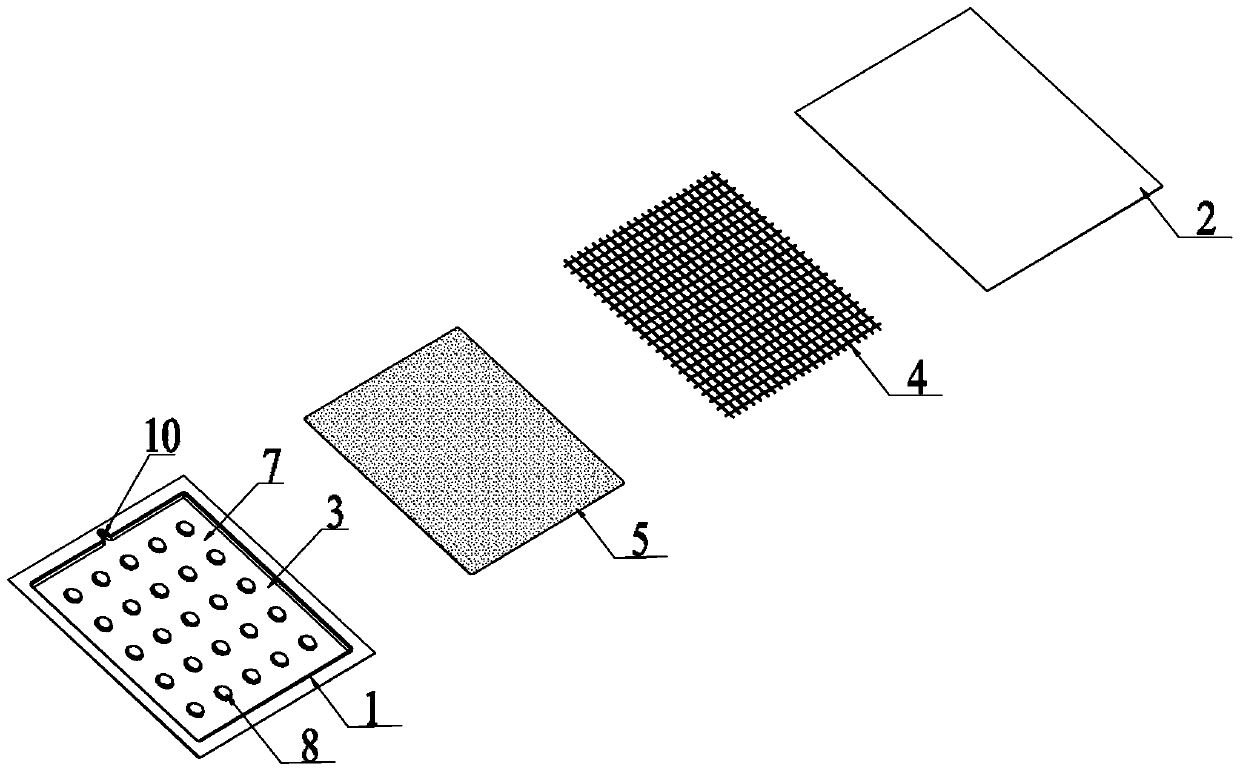

[0028] Such as Figure 1 ~ Figure 3 As shown, a compound type vapor chamber of the present invention includes a first cover plate 1, a second cover plate 2 and a cavity 3, the first cover plate 1 and the second cover plate 2 are closed and connected, and the cavity 3 It is provided with a supporting structure, a powder sintered capillary structure 4 and a suction liquid injection port 6 connected with the cavity 3, and it also includes a mesh capillary structure 5, and a groove 7 is opened on the cover surface of the first cover plate 1 A cavity 3 is formed, and the support structure is a convex hull 8 formed integrally with the first cover plate 1 by sheet metal stamping. The convex hulls 8 are arranged in a matrix of 5×5 on the bottom surface of the groove 7, and the height of the convex hull 8 is smaller than that of the concave groove. The depth of the groove 7, the powder sintered capillary structure 4 is close to the cover plate surface of the second cover plate 2, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com