Optical imaging lens and imaging equipment

An optical imaging lens and lens technology, applied in optics, optical components, instruments, etc., can solve the problem of difficult correction of lens edge aberration, achieve good imaging effect, reduce the total length, and reduce the effect of axial chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

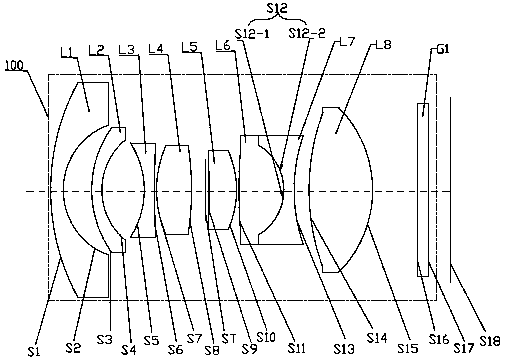

[0082] See figure 1 The optical imaging lens 100 provided by the first embodiment of the present invention is composed of eight lenses, from the object side to the imaging surface, including: a first lens L1, a second lens L2, a third lens L3, a fourth lens L4, Stop ST, fifth lens L5, sixth lens L6, seventh lens L7, eighth lens L8, and filter G1.

[0083] The first lens L1 has a negative refractive power, the object side surface S1 is a convex surface, the image side surface S2 is a concave surface, and the first lens L1 is a glass spherical lens.

[0084] The second lens L2 has a negative refractive power, the object side surface S3 is a convex surface, the image side surface S4 is a concave surface, and the second lens L2 is a glass aspheric lens.

[0085] The third lens L3 has a negative refractive power, the object side S5 and the image side S6 are both concave, and the third lens L3 is a glass spherical lens. In other embodiments of the present invention, the third lens L3 may ...

no. 2 example

[0100] For a schematic structural diagram of the optical imaging lens 200 of this embodiment, please refer to Figure 4 . The optical imaging lens 200 in this embodiment is substantially the same as the optical imaging lens 100 in the first embodiment, except that the image side surface S6 of the third lens L3 of the optical imaging lens 200 in this embodiment is convex, and The curvature radius and material selection of each lens are different.

[0101] The relevant parameters of each lens in the optical imaging lens 200 in this embodiment are shown in Table 3.

[0102] table 3

[0103]

[0104] The aspheric parameters of each lens in this embodiment are shown in Table 4.

[0105] Table 4

[0106]

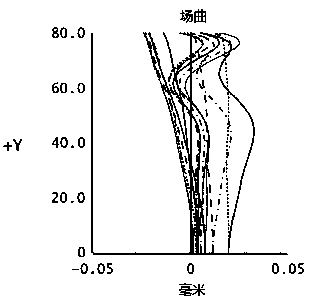

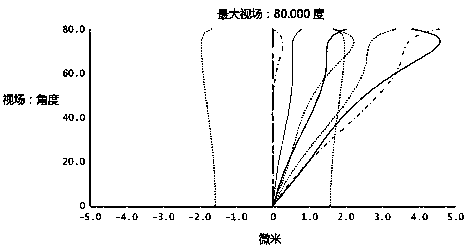

[0107] In this embodiment, its curvature of field and vertical axis chromatic aberration are as Figure 5 with Image 6 Shown. by Figure 5 with Image 6 It can be seen that the curvature of field and vertical axis chromatic aberration can be well corrected in this embodiment.

no. 3 example

[0109] For a schematic structural diagram of an optical imaging lens 300 provided in this embodiment, please refer to Figure 7 . The optical imaging lens 300 in this embodiment is substantially the same as the optical imaging lens 100 in the first embodiment. The difference is that the image side surface S6 of the third lens L3 of the optical imaging lens 300 in this embodiment is convex. The object side surface S7 of the four lens L4 is convex, and the curvature radius and material selection of each lens are different.

[0110] The relevant parameters of each lens in the optical imaging lens 300 in this embodiment are shown in Table 5.

[0111] table 5

[0112]

[0113] The aspheric parameters of each lens in this embodiment are shown in Table 6.

[0114] Table 6

[0115]

[0116] In this embodiment, its curvature of field and vertical axis chromatic aberration are as Figure 8 with Picture 9 Shown. by Figure 8 with Picture 9 It can be seen that the curvature of field and vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com