Dehydration drying device for mushroom processing

A technology for dehydrating and drying mushrooms, which is applied in food processing, application, food processing, etc. It can solve the problems of mushroom pollution, poor product appearance, and loss of mushroom fragrance, etc., and achieve the effect of uniform and sufficient heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The purpose of the present invention can be achieved through the following technical solutions:

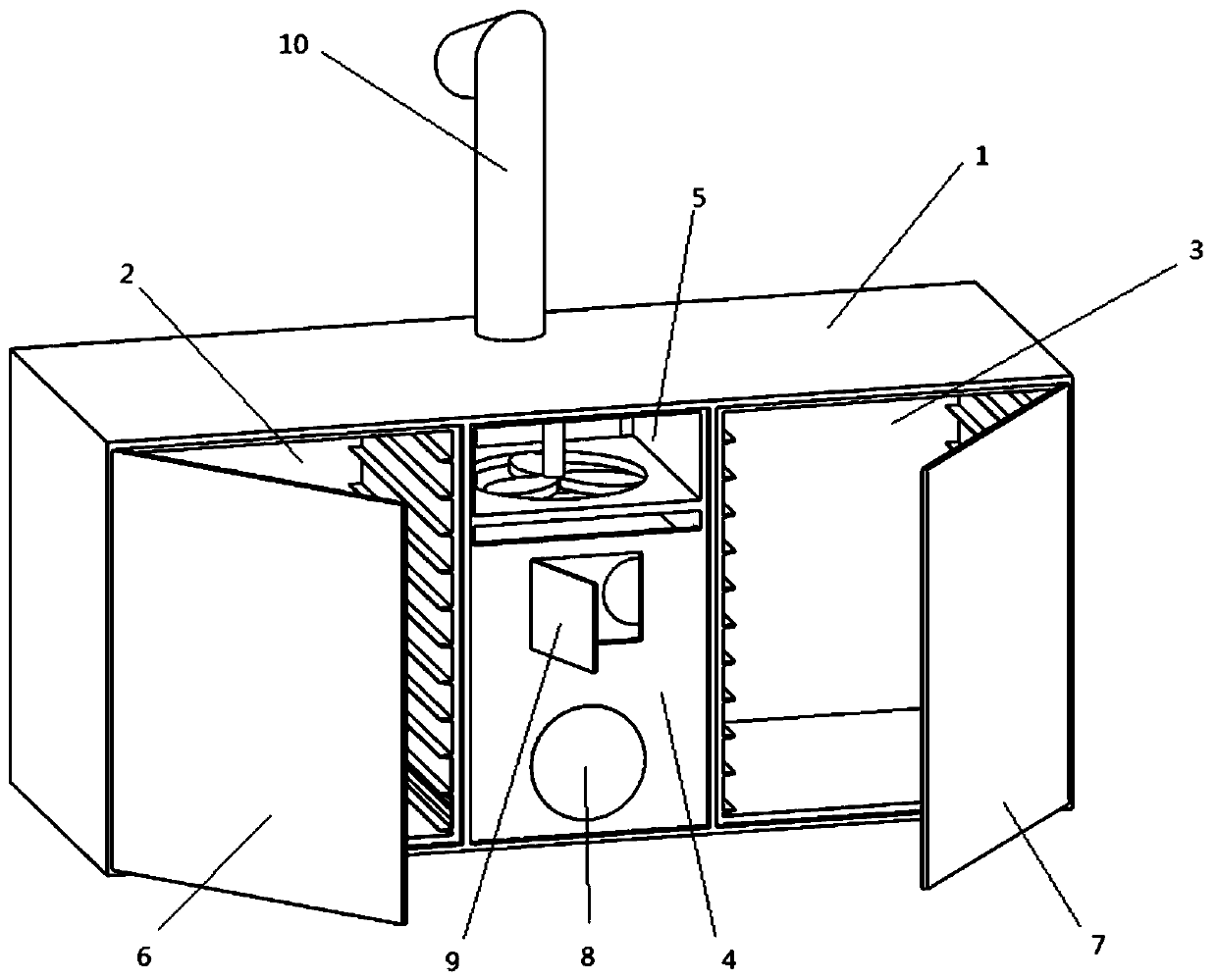

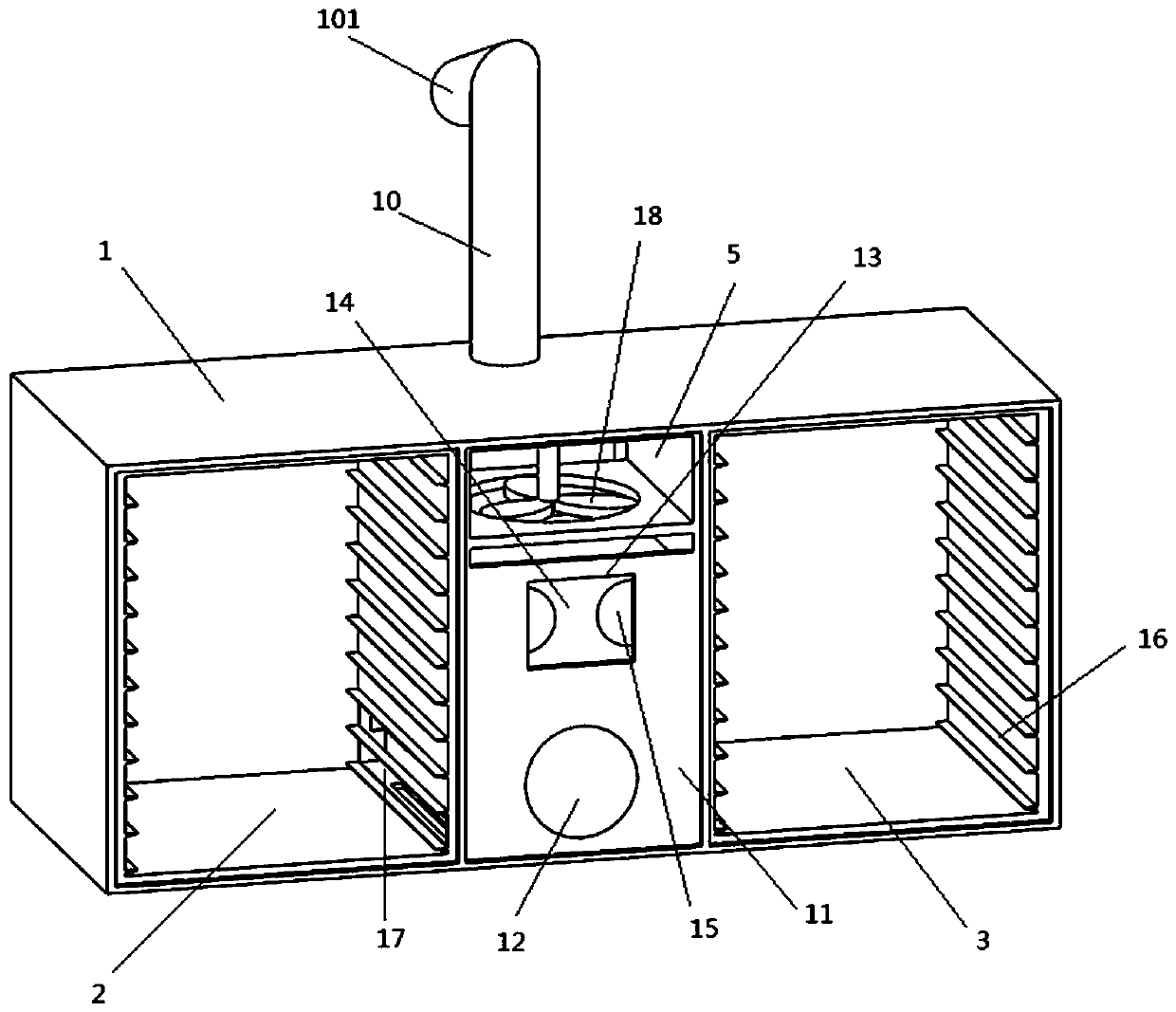

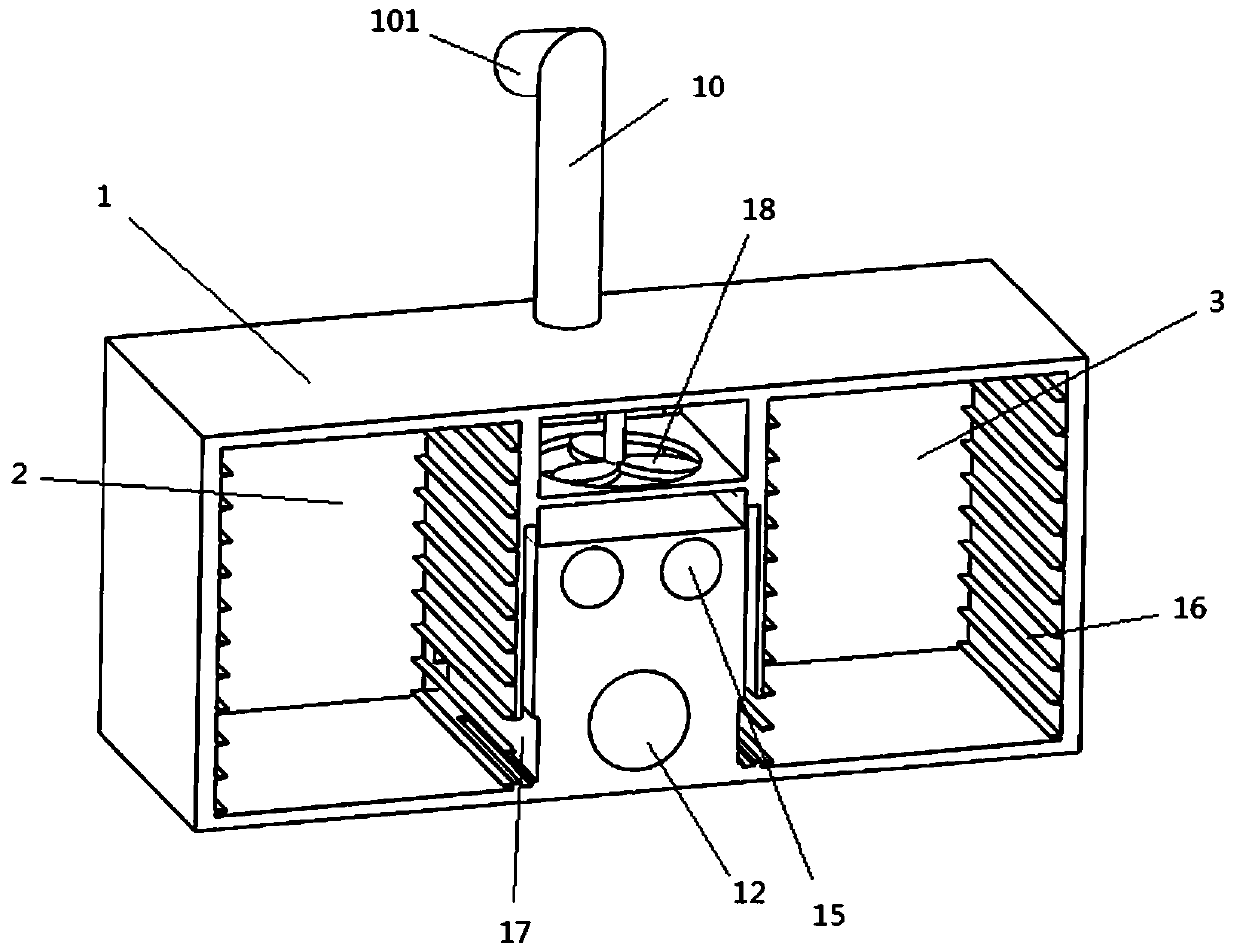

[0028] A dehydration and drying device for mushroom processing, see Figure 1~5 , including box body 1, first baking chamber 2, second baking chamber 3, heat source chamber 4, diffusion chamber 5, first chamber door 6, second chamber door 7, furnace door 8, heat source chamber door 9, smoke Tube 10, heat source front cover 11, furnace chamber 12, heat source cavity cleaning hole 13, heat conductor 14, heat conduction through hole 15, mounting lug 16, heat diffusion hole 17, heat diffusion fan 18, heat dissipation hole 20, fan frame 21, fan shaft 22. Fan motor 23;

[0029] The box body 1 is provided with a first baking cavity 2, a second baking cavity 3, a heat source cavity 4, and a diffusion cavity 5, and the first baking cavity 2 and the second baking cavity are respectively arranged on both sides of the heat source cavity 4. 3. The top of the heat source chamber 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com