High Strength Chain Welder

A high-strength, welding machine technology, applied in welding equipment, resistance welding equipment, welding/welding/cutting items, etc., can solve problems such as automatic deburring, unstable welding quality, and affecting product appearance, etc., to achieve replaceability Strong, stable welding quality, low failure rate and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, and this embodiment does not constitute a limitation to the present invention.

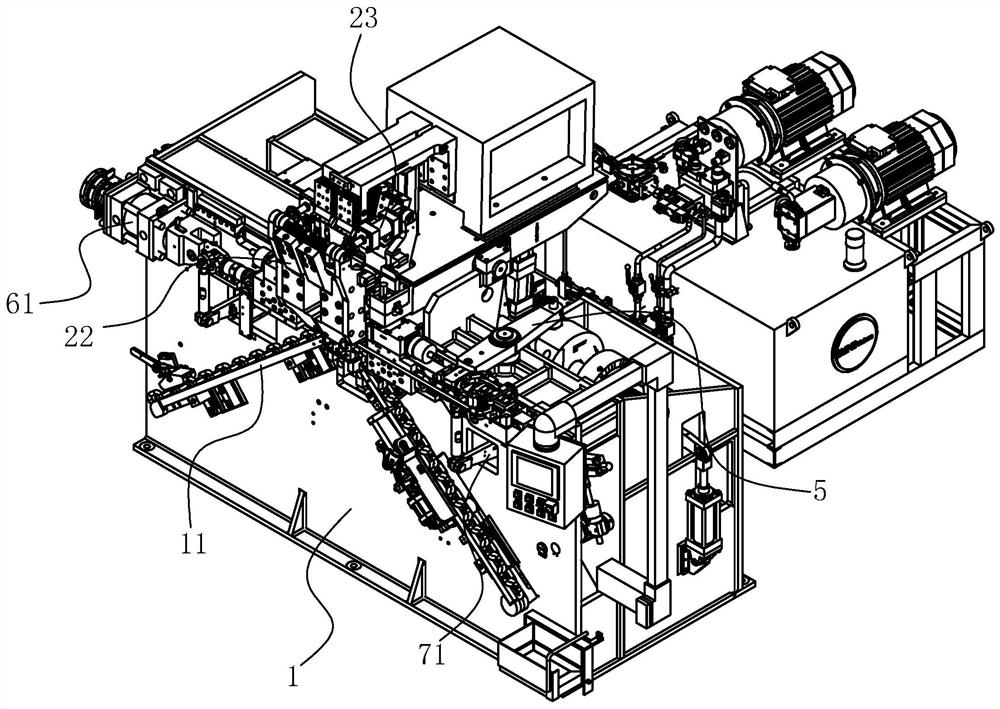

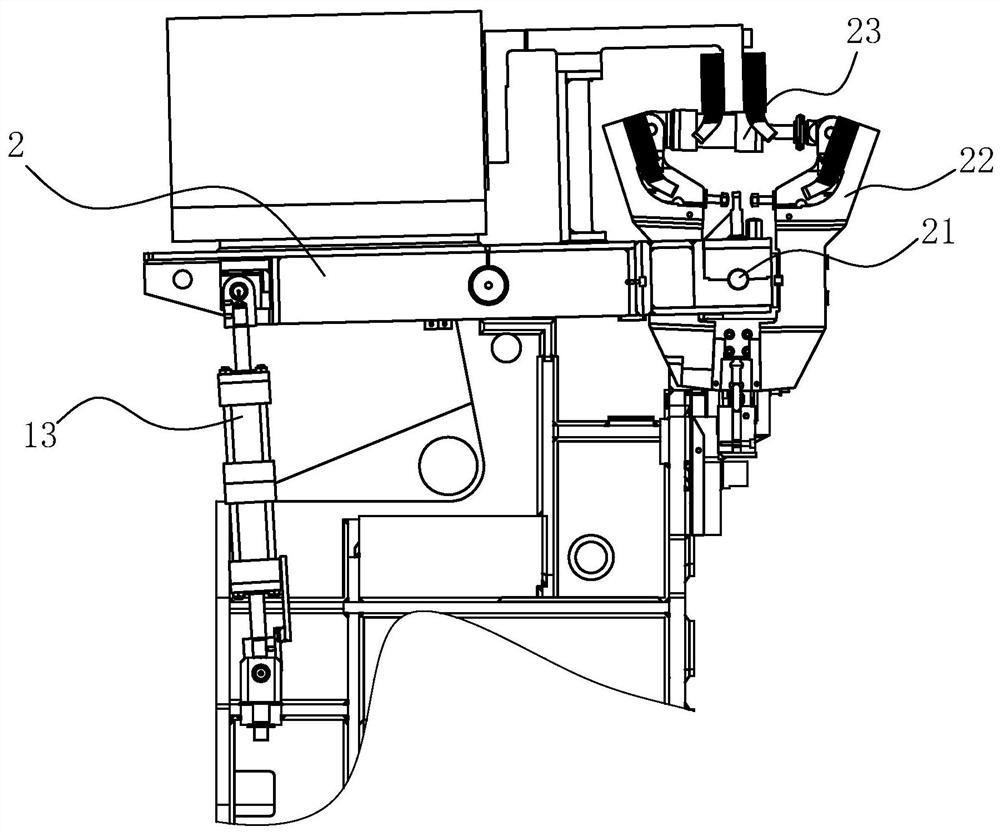

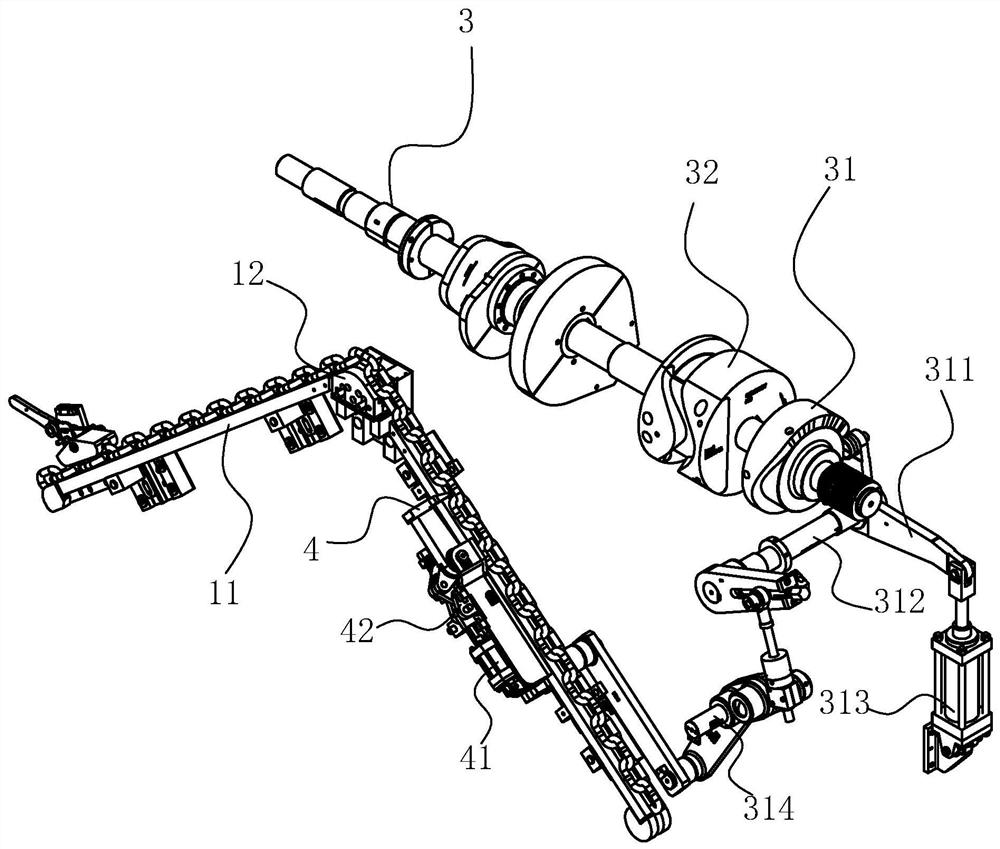

[0033] Such as figure 1 with figure 2 As shown, a high-strength chain welding machine includes a welding machine main body 1. The welding machine main body 1 is connected with a chain feeding straightening guide rail 11 for guiding the chain. The welding machine main body 1 is also connected with an anvil 12, and the chain feeding straightening rail 11 comprises two that are positioned at anvil block 12 both sides respectively, and two delivery chain righting guide rails 11 are inclined upward near the end of anvil block 12, and the chain link to be welded is positioned on anvil block 12, and the vertical chain link on both sides of the chain ring to be welded is positioned at the feeder. In the chain straightening guide rail 11, the anvil 12 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com