Control method for workpiece machining deformation

A technology of machining deformation and control method, which is applied in the field of residual stress machining deformation control, and can solve the problems of large deformation of workpiece, high thermal aging energy consumption, and poor control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

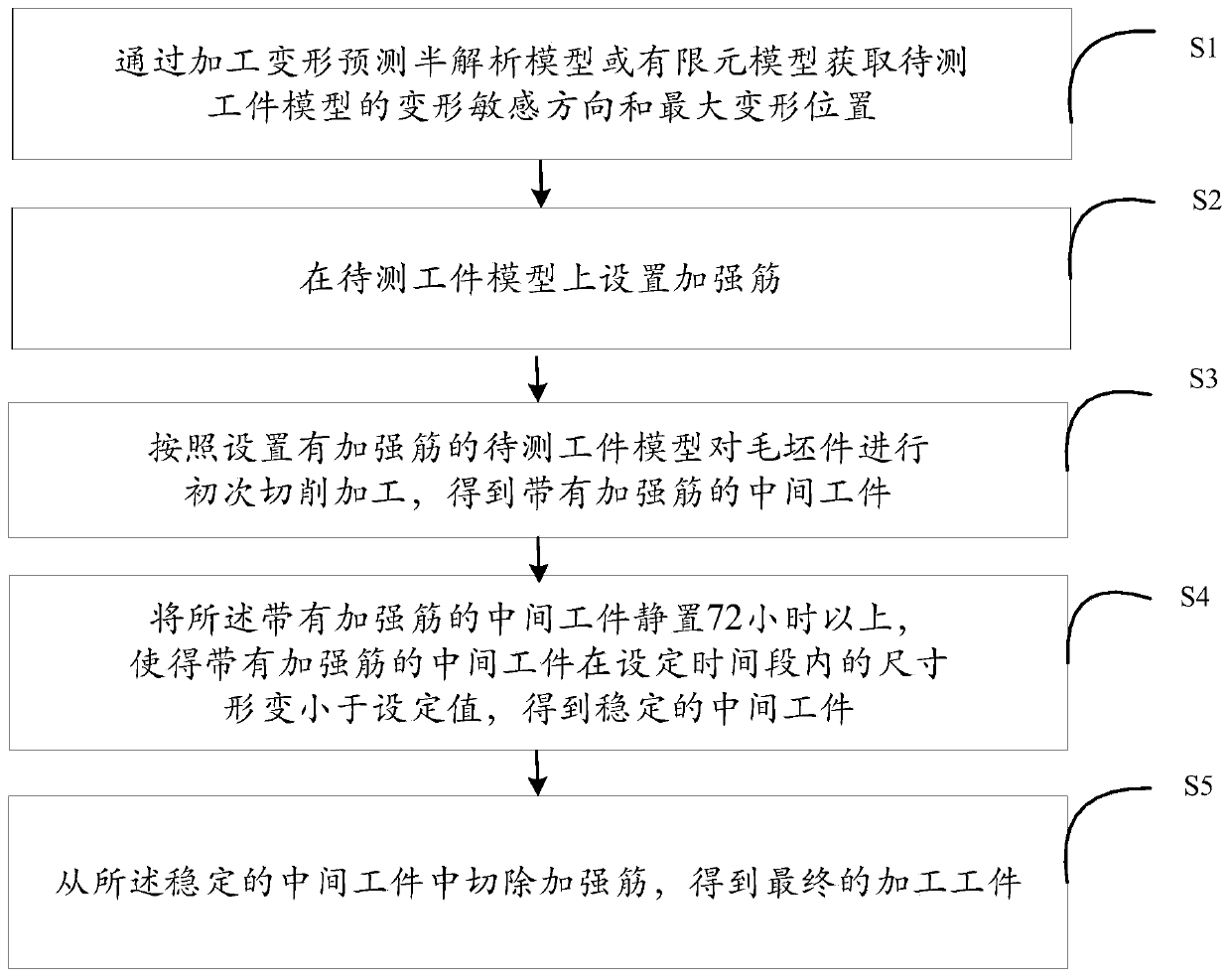

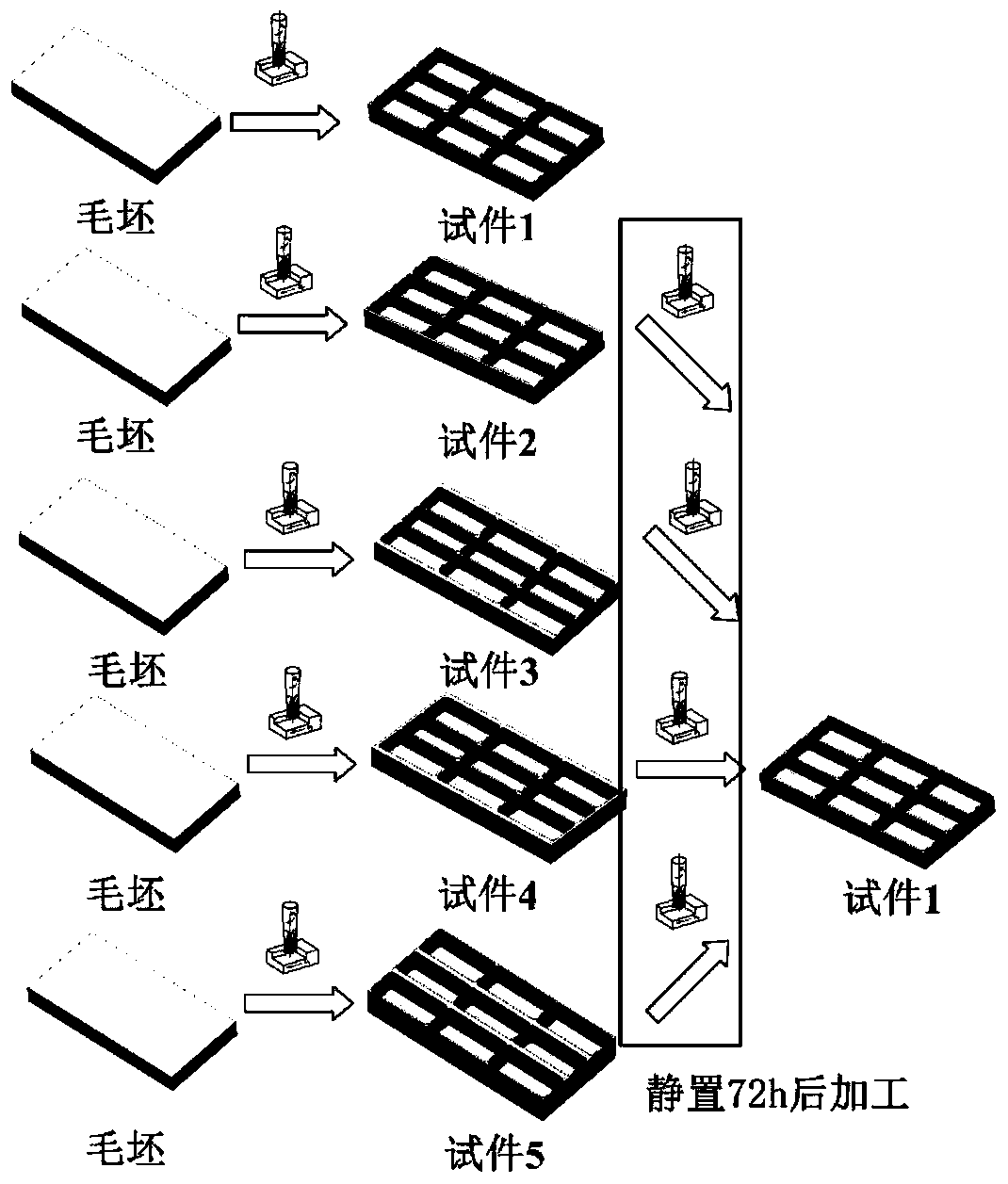

[0020] see figure 1 , which is a flow chart of a method for controlling workpiece machining deformation provided in this embodiment. A method for controlling workpiece machining deformation, comprising the following steps:

[0021] S1: Obtain the deformation sensitive direction and maximum deformation position of the workpiece model to be measured through the processing deformation prediction semi-analytical model or finite element model.

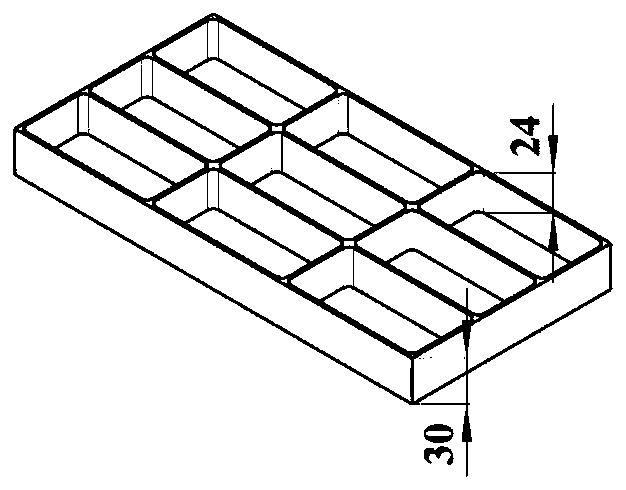

[0022] S2: setting reinforcing ribs on the workpiece model to be tested, wherein the setting of the reinforcing ribs meets the following conditions:

[0023] The direction of the rib is parallel to the deformation sensitive directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com