Synergist for enhancing fertilizer particle strength and application thereof

A technology of fertilizer granules and synergist, applied in the directions of application, fertilizer mixture, fertilization method, etc., can solve the problems of unsatisfactory fertilizer granule strength enhancement effect, low granule strength, pulverization and crushing, etc., and achieves good effect of machine fertilization. , The effect of high particle internal force and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

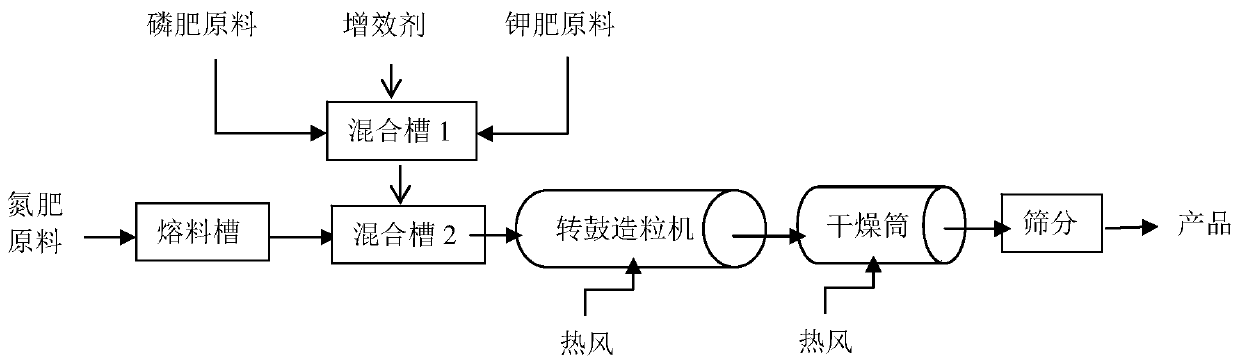

[0040] Based on the above-mentioned granular fertilizer, the embodiment of the present invention also provides a preparation method of the above-mentioned granular fertilizer. The preparation method technology of described granular fertilizer is as figure 1 As shown, it includes the following steps:

[0041] S01: Mix the synergist mentioned above with the components of the granular fertilizer base to obtain a fertilizer mixture;

[0042] S02: Granulating the fertilizer mixture.

[0043] Wherein, the synergist and the composition of the granular fertilizer base in the step S01 are as described above in the granular fertilizer example, specifically, the synergist is the synergist described above. The granular fertilizer base component may be a fertilizer base component suitable for preparing granular fertilizer. In one embodiment, the synergist is mixed with the granular fertilizer base components at a ratio of 3wt%-6wt% of the synergist in the granular fertilizer.

[0044] ...

Embodiment 11

[0056] The embodiment of the present invention provides a synergist. Based on 100 parts by weight of the total amount of the synergist components, the following components are included:

[0057] Bentonite: 20 parts

[0058] Modified metal silicate: 60 parts

[0059] Polyvinyl alcohol: 20 parts

Embodiment 12

[0061] The embodiment of the present invention provides a synergist. Based on 100 parts by weight of the total amount of the synergist components, the following components are included:

[0062] Bentonite: 30 parts

[0063] Modified metal silicate: 50 parts

[0064] Polyvinyl alcohol: 20 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com