Anti-hardening strip packed BOPP thin film for ultra-smooth cigarettes and preparation method thereof

An anti-caking, super cool technology, applied in chemical instruments and methods, applications, household components, etc., can solve problems such as lost customers, film waste, unrealistic, etc., to reduce film stripping, low surface resistance, and smoothness improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

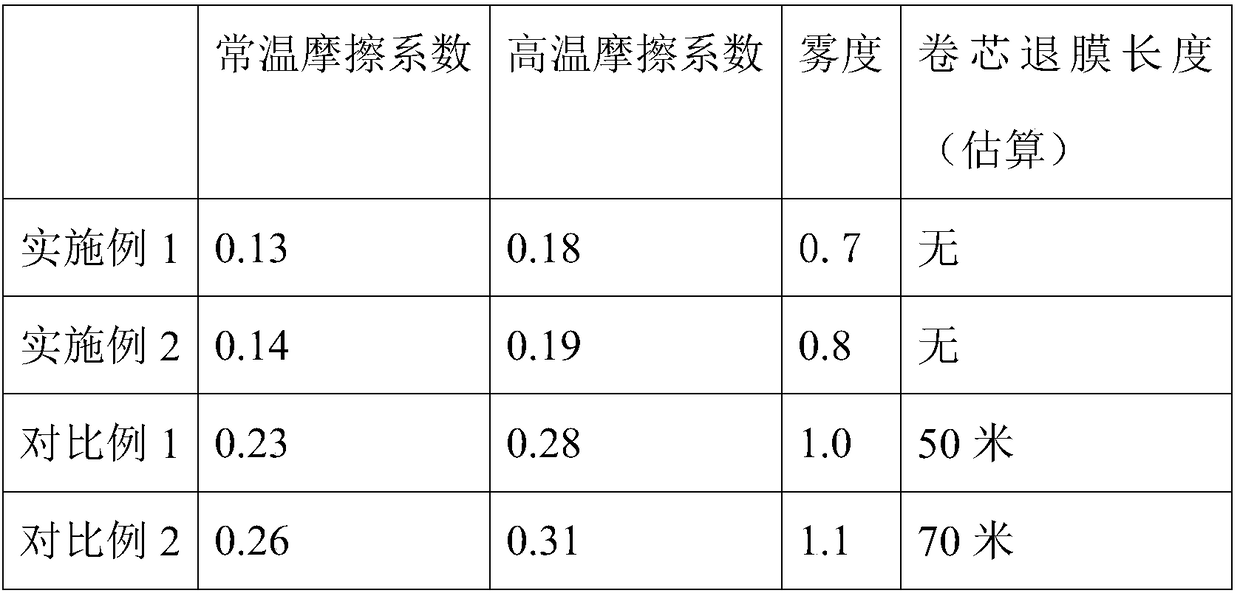

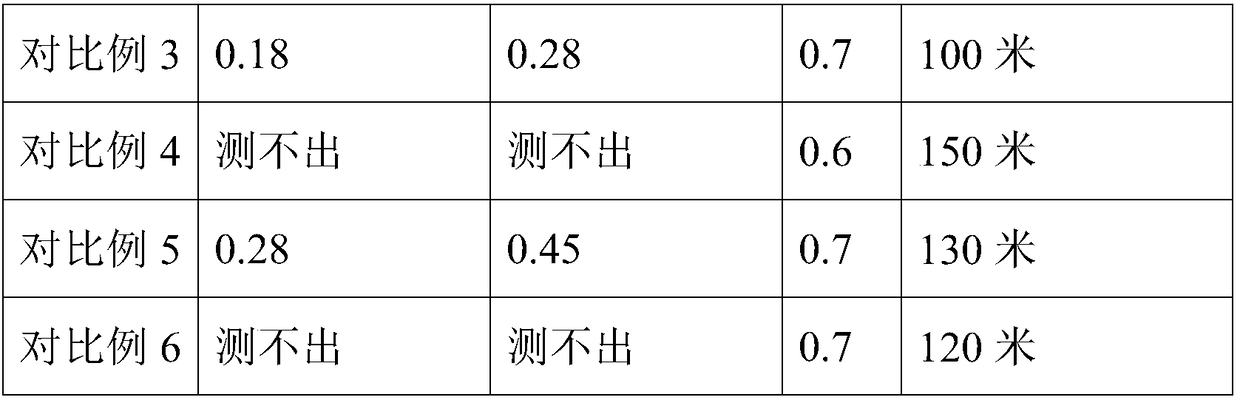

Embodiment 1

[0036] Raw material formula:

[0037] (1) Upper surface layer

[0038] Copolymer polypropylene 86 parts by weight

[0039] 12 parts by weight of slip agent masterbatch

[0040] 2 parts by weight of anti-adhesive masterbatch

[0041] The carrier of slip agent masterbatch and anti-adhesive masterbatch is polypropylene copolymer, the active ingredient of slip agent masterbatch is high-viscosity silicone, the concentration is 10%; the active ingredient of anti-adhesive masterbatch is synthetic resin, the concentration is is 5%.

[0042] (2) core layer

[0043] 79 parts by weight of homopolymer polypropylene

[0044] Stiffening agent masterbatch 18 parts by weight

[0045] 3 parts by weight of antistatic agent masterbatch

[0046] The carrier of stiffening agent masterbatch and antistatic agent masterbatch is homopolymer polypropylene. The active ingredient of the stiffener masterbatch has a melting point of 160°C and a C 9 The hydrogenated resin, the active ingredient of ...

Embodiment 2

[0058] The production process and components are basically the same as in Example 1, except that the raw material formulation is different.

[0059] Raw material formula:

[0060] (1) Upper surface layer

[0061] Copolymer polypropylene 88 parts by weight

[0062] 10 parts by weight of slip agent masterbatch

[0063] 2 parts by weight of anti-adhesive masterbatch

[0064] (2) core layer

[0065] 75 parts by weight of homopolymer polypropylene

[0066] Stiffening agent masterbatch 22 parts by weight

[0067] 3 parts by weight of antistatic agent masterbatch

[0068] (3) Lower surface layer

[0069] Copolymer polypropylene 97 parts by weight

[0070] Slippery agent masterbatch 2 parts by weight

[0071] 1 part by weight of anti-adhesive masterbatch

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com