Polishing liquid for KDP crystals and preparation method and application of polishing liquid

A technology of polishing liquid and crystal, applied in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as damage and atomization of KDP crystal surface, and achieve the effect of simple steps, stable properties and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The prepared polishing liquid is used for KDP crystal polishing, the specific process is:

[0041] 1) Obtaining the initial surface: the KDP crystal with a diameter of 50mm cut by single-point diamond is used as the crystal to be polished, and the surface roughness is 3.5nm;

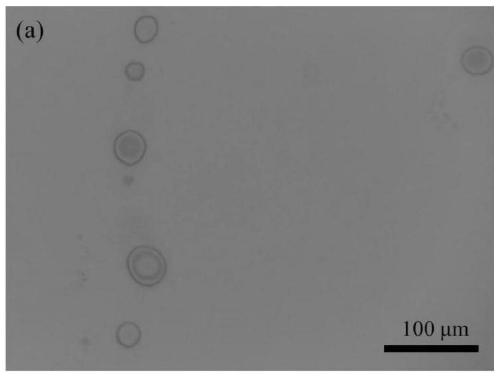

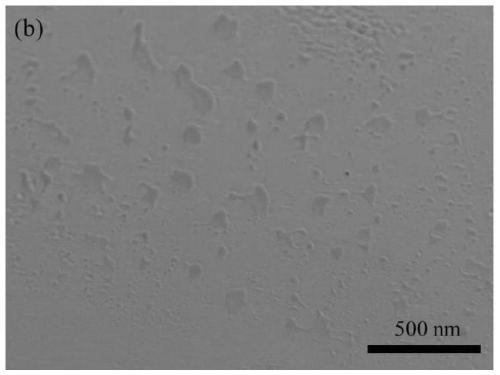

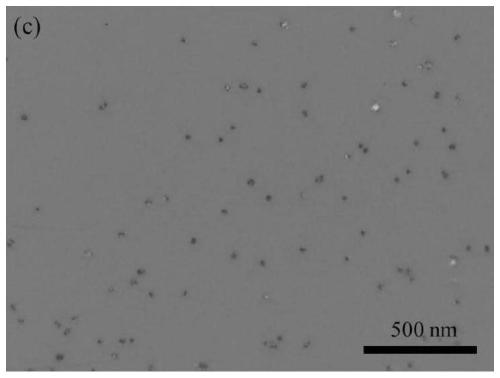

[0042] 2) Preparation of polishing solution: mix the non-polar phase (cyclohexane) and the dual-solvent phase (isopropanol) according to a certain volume ratio, and after magnetically stirring evenly, add a certain volume of polar phase to the mixed solvent dropwise (water), the volume ratio of hexanaphthene, isopropanol and water in the final system is 36:604, leave standstill after stirring evenly, and seal up for subsequent use; In order to compare the advantages of the polishing solution of the present invention and the traditional water-in-oil microemulsion, we use The water-in-oil microemulsion formed in the ratio of oil phase (decanol), surfactant (TX-100) and water is 36:60:4 as the polish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com