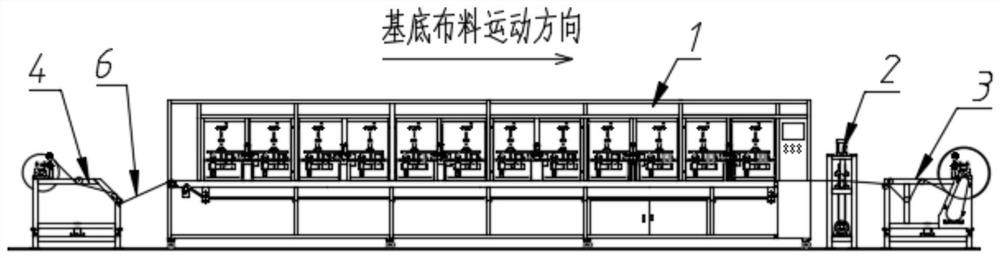

A plane receiving centrifugal spinning device

A technology of centrifugal spinning and collecting device, applied in textiles and papermaking, filament/thread forming, non-woven fabrics, etc., can solve problems such as low efficiency, low safety factor, and inability to achieve continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

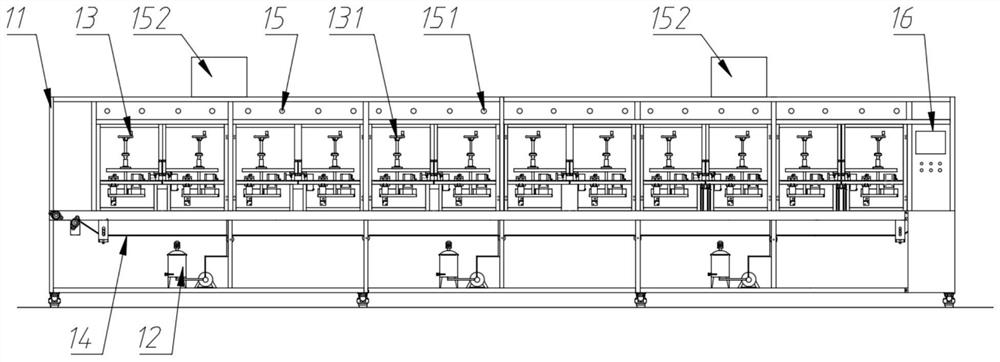

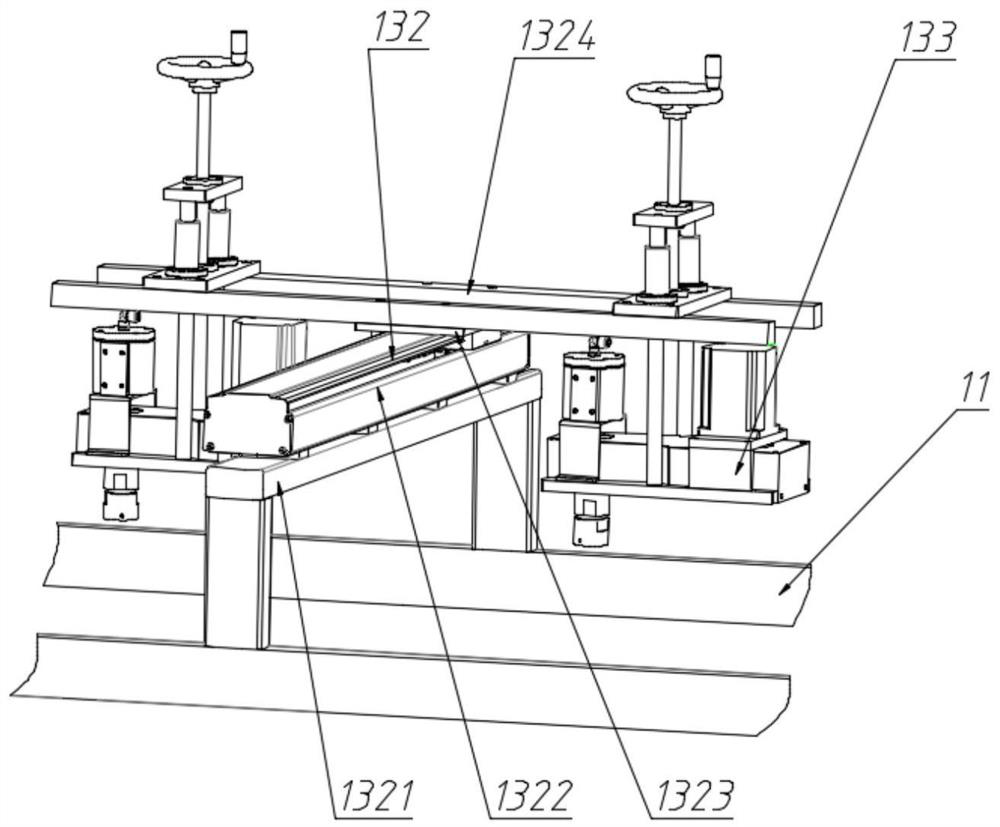

[0055] Such as figure 2 As shown, a plane receiving type centrifugal spinning device comprises a frame 11, a feeding device 12, a spinning device 13, a collection device 14, a temperature control device 15 and a control system 16; the feeding device 12 is fixedly installed on the machine The bottom of the frame 11; the temperature control device 15 is fixedly mounted on the top of the frame 11; the collecting device 14 is fixedly mounted on the middle part of the frame 11; the spinning device 13 is arranged above the collecting device 14, And it is fixedly installed on the frame 11; the control system 16 is fixedly installed on one side of the frame 11.

[0056] The feeding device 12 supplies materials to the spinning device 13; the spinning device 13 performs centrifugal spinning; the collecting device 14 collects the centrifugal spinning fiber web made by the spinning device 13; the temperature control The device 15 adjusts the temperature of the spinning environment in th...

Embodiment 2

[0086] The difference with Embodiment 1 is that, in the spinner device 133 among the embodiment 2, at least one spinneret 1354 is installed on its said spinneret 134; The shape of the spinneret shown is as follows Figure 8 As shown, its inner diameter gradually becomes smaller to form a cone; the spinning solution in the spinneret 134 is ejected through the spinneret 1354 .

Embodiment 3

[0088] The difference with embodiment 1 is that, in the spinner device 133 in embodiment 3, at least one spinneret 1354 is installed on its described spinneret 134; The shape of shown spinneret is as follows Figure 9 As shown, its structure is in the form of steps; the spinning solution in the spinneret 134 is ejected through the spinneret 1354 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com