A kind of wind power generation device

A technology for wind power generation devices and generators, which is applied in the direction of wind power generation, wind power engines, and wind power motor combinations. Achieve the effects of improving the power generation capacity of a single machine, reducing unbalanced loads, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

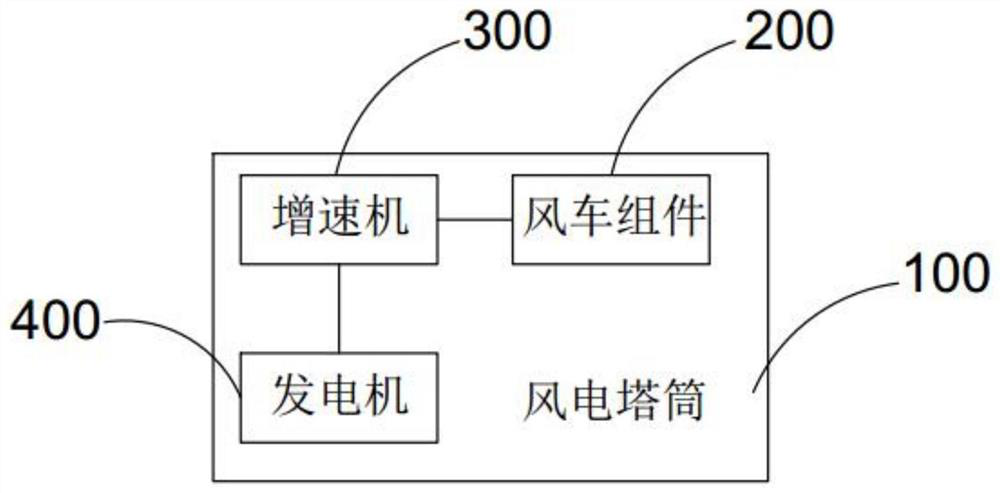

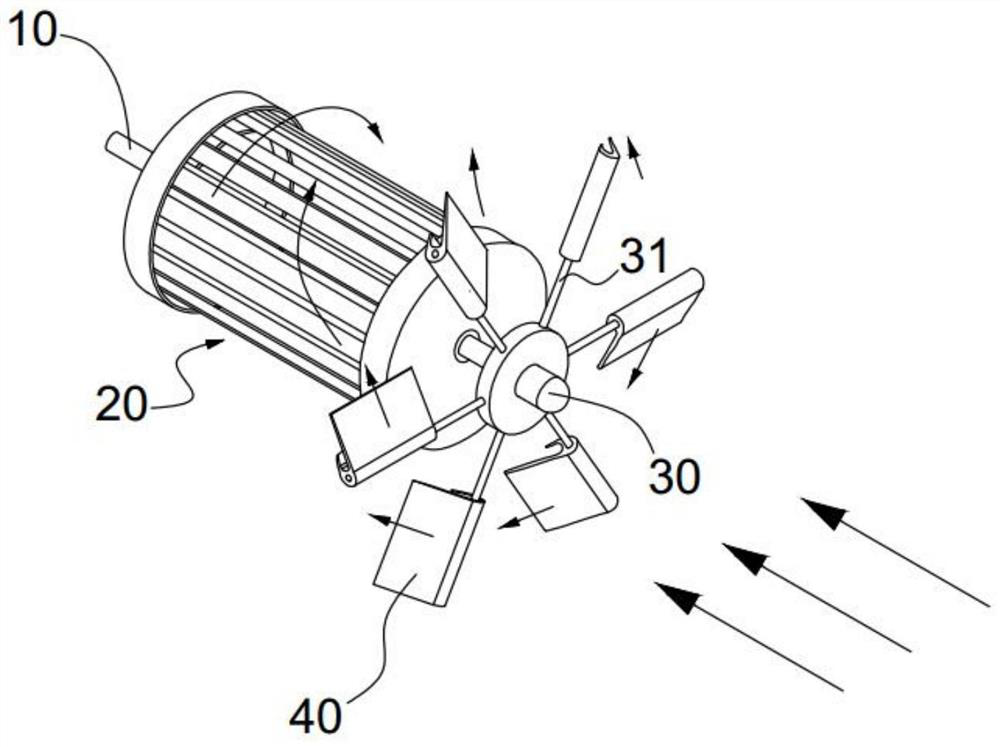

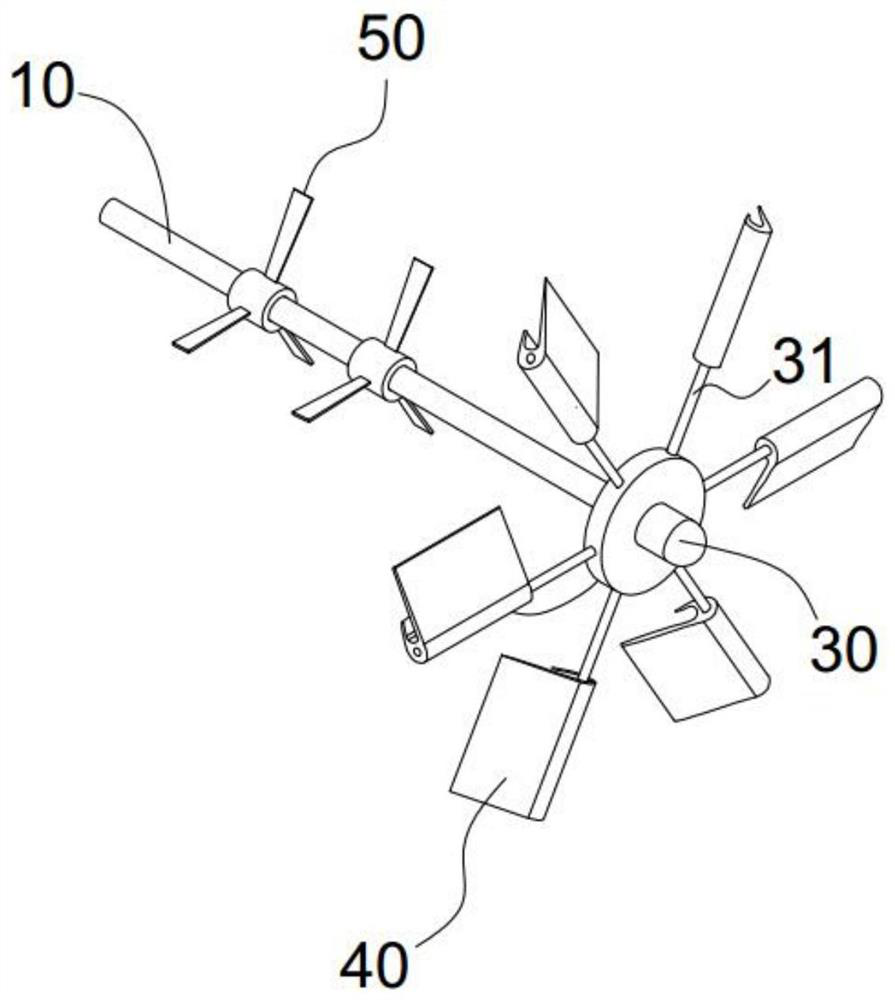

[0035] see Figure 1-8 As shown, a wind power generation device includes: a windmill assembly 200, and the windmill assembly 200 includes:

[0036] Spindle 10,

[0037] The first driving assembly is used to drive the rotating shaft 10 to rotate, the first driving assembly is installed on the end of the rotating shaft 10,

[0038] The second driving assembly 20 is used to drive the rotating shaft 10 to rotate, and the second driving assembly 20 is installed on the rotating shaft 10 along the axis of the rotating shaft 10 ,

[0039] Wherein, the first driving assembly includes a turntable 30 connected to the end of the rotating shaft 10 and coaxial with it. A connecting rod 31 is connected around the rotating disk 30. The axis of the connecting rod 31 is perpendicular to the axis of the rotating shaft 10. The first blade 40 is connected to the connecting rod 31. , the first vane 40 has a first assembly hole 41 for assembling with the connecting rod 31 , and one side of the first...

Embodiment 2

[0053] The connecting rod 31 of the present invention is a cylindrical rod, which is arranged around the annular side of the turntable 30, and the angle between the connecting rods 31 is 60°, of course it can also be 120°, but the angle between the connecting rods 31 should be equal. The guide vanes 23 are bent plate-shaped, and the bending angle is between 75° and 135° to realize the drainage of the wind. They are fixedly connected by bonding or welding, and the first vane 40 is interference fitted with the connecting rod 31 through the first assembly hole 41, and welding can be performed if necessary.

Embodiment 3

[0055] When the wind power generation device of the present invention is actually used: the first drive assembly is driven by the wind to generate rotational motion, which drives the rotating shaft 10 to rotate, and then increases the rotational speed through the speed increaser to make the generator 400 generate electricity. In the process of wind power generation, the first The second driving assembly 20 captures the wind of different wind directions, and further captures the spiral backward wind formed by the first driving assembly for a second time, and guides the wind flowing through the second driving assembly 20 to make it flow along the guide vanes. 23 flows into the second driving assembly 20, and forms an annular wind flow to drive the second blade 52 of the second driving assembly 50 to rotate, so as to increase the rotation speed of the rotating shaft 10 and realize the speed-up effect.

[0056] In order to test the stress situation of the first blade 40, the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com