An inner-column-outer-ring dual-zone composite solder joint structure and hybrid bonding method

A composite solder joint and core structure technology, applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as oxidation, chip failure surface, and inability to bond, so as to reduce process difficulty and save process cost , to avoid the effect of bonding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below.

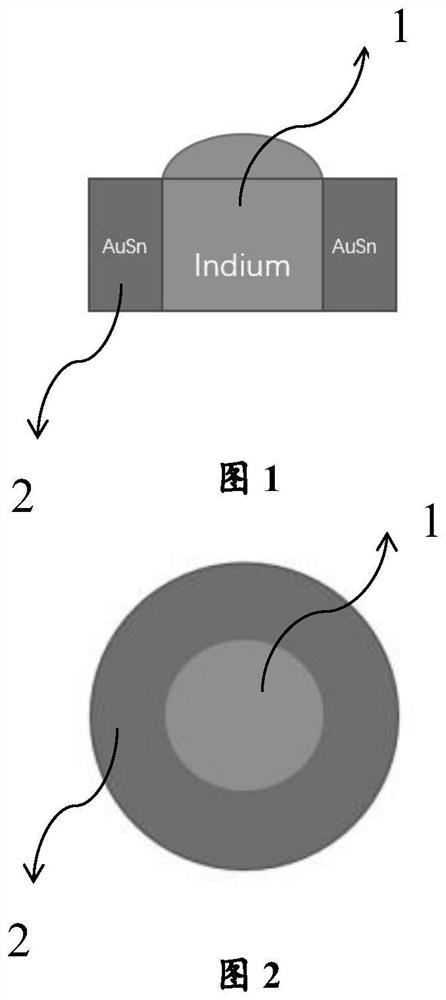

[0036] A double-zone composite solder joint structure with inner column and outer ring, such as Figure 1-2 As shown, it includes an inner core pillar 1 and a peripheral ring 2. The inner core pillar 1 uses metal indium, and the outer ring 2 uses a gold-tin alloy.

[0037] The method for preparing the above-mentioned inner column outer ring type double zone composite solder joint structure includes the following steps:

[0038] (1) Coating photoresist on the surface of the wafer, the thickness of the photoresist is 25μm;

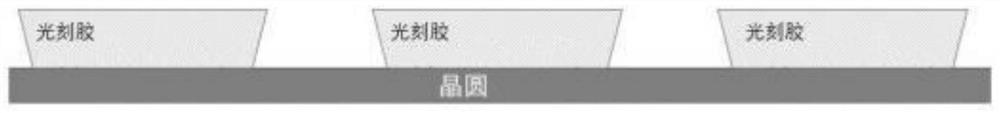

[0039] (2) The wafer coated with photoresist in step (1) is sequentially exposed, developed and baked, and the resulting photoresist pattern has an inverted trapezoidal morphology on the surface of the wafer; image 3 Shown

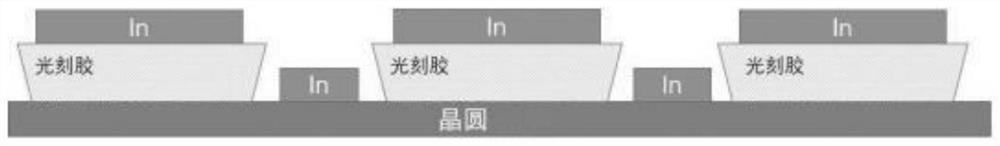

[0040] (3) Deposit metal indium on the surface of the photoresist pattern in step (2) by evaporation, and deposit metal indium on the surface of the wafer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com