Braiding machine and method for making braided fabric

A knitting machine and braiding technology, applied in the field of knitting machines, can solve problems such as negative impact on quality and mechanical complexity, and achieve the effects of reducing mechanical load, high quality, and avoiding mechanical friction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

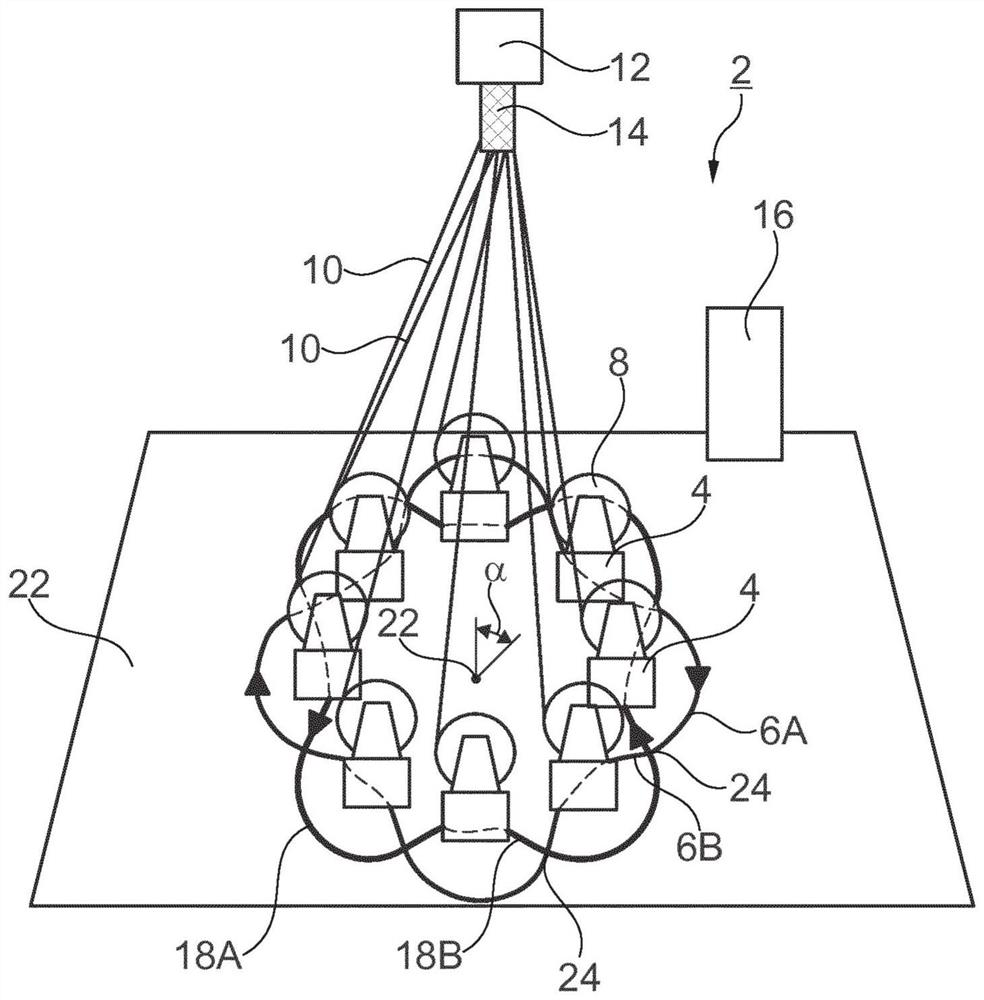

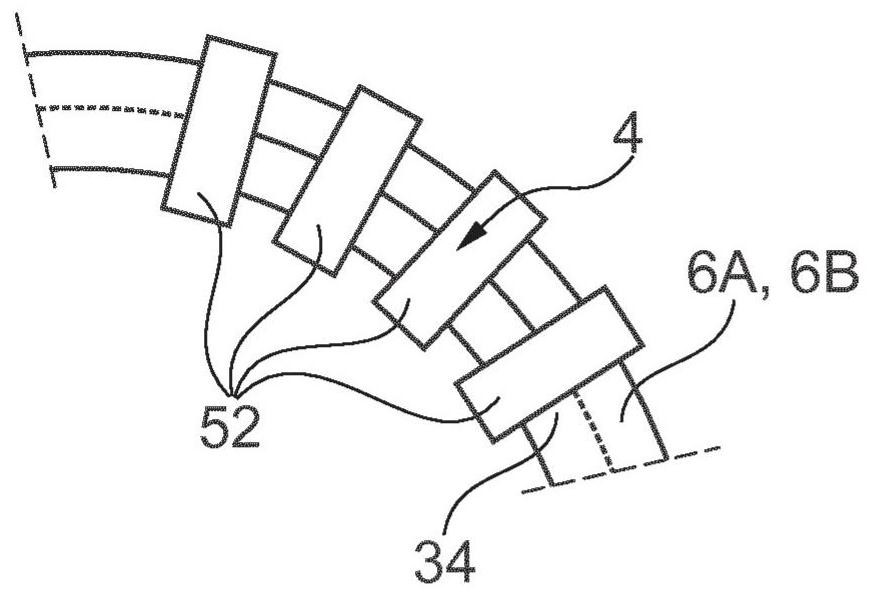

[0039] figure 1 The knitting machine 2 shown in has a plurality of roll carriers 4 movable along predetermined trajectories 6A, 6B. The respective reel carriers 4 each have a reel 8 on which the wire 10 is wound. The knitting machine 2 also has a pulling device 12 for the knitting fabric 14 formed during the knitting process. The knitting machine 2 and the knitting process are controlled by means of the control device 16 .

[0040] The two tracks 6A, 6B are designed as circumferentially closed undulating tracks. In the present exemplary embodiment, they each have four outwardly curved convex sections 18A and correspondingly inwardly curved concave sections 18B. In this case, the curved sections 18A, 18B are each formed uniformly distributed at the same angular distance from one another. The two tracks 6A, 6B are constructed identically to one another, but are arranged relative to one another at a twisted angle α around the central axis 20 . In this embodiment, the twist a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com