Multifunctional tobacco sowing system

A multi-functional tobacco technology, which is applied in the fields of flower pot filling, horticulture, botany equipment and methods, etc., can solve the problems of inconvenient fixing of seedling trays of different sizes and low tobacco planting efficiency, and achieve the goal of improving planting and cultivation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

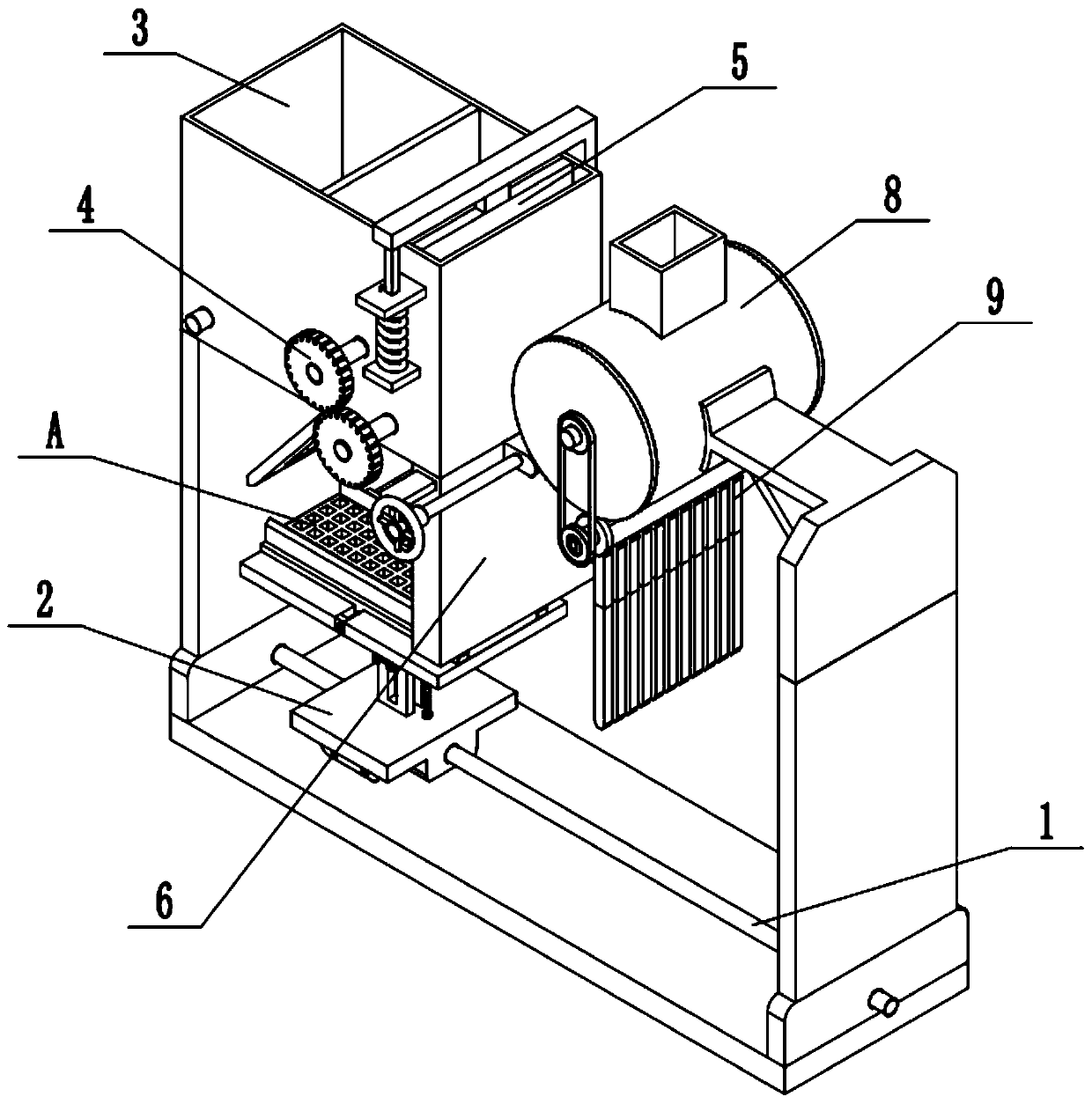

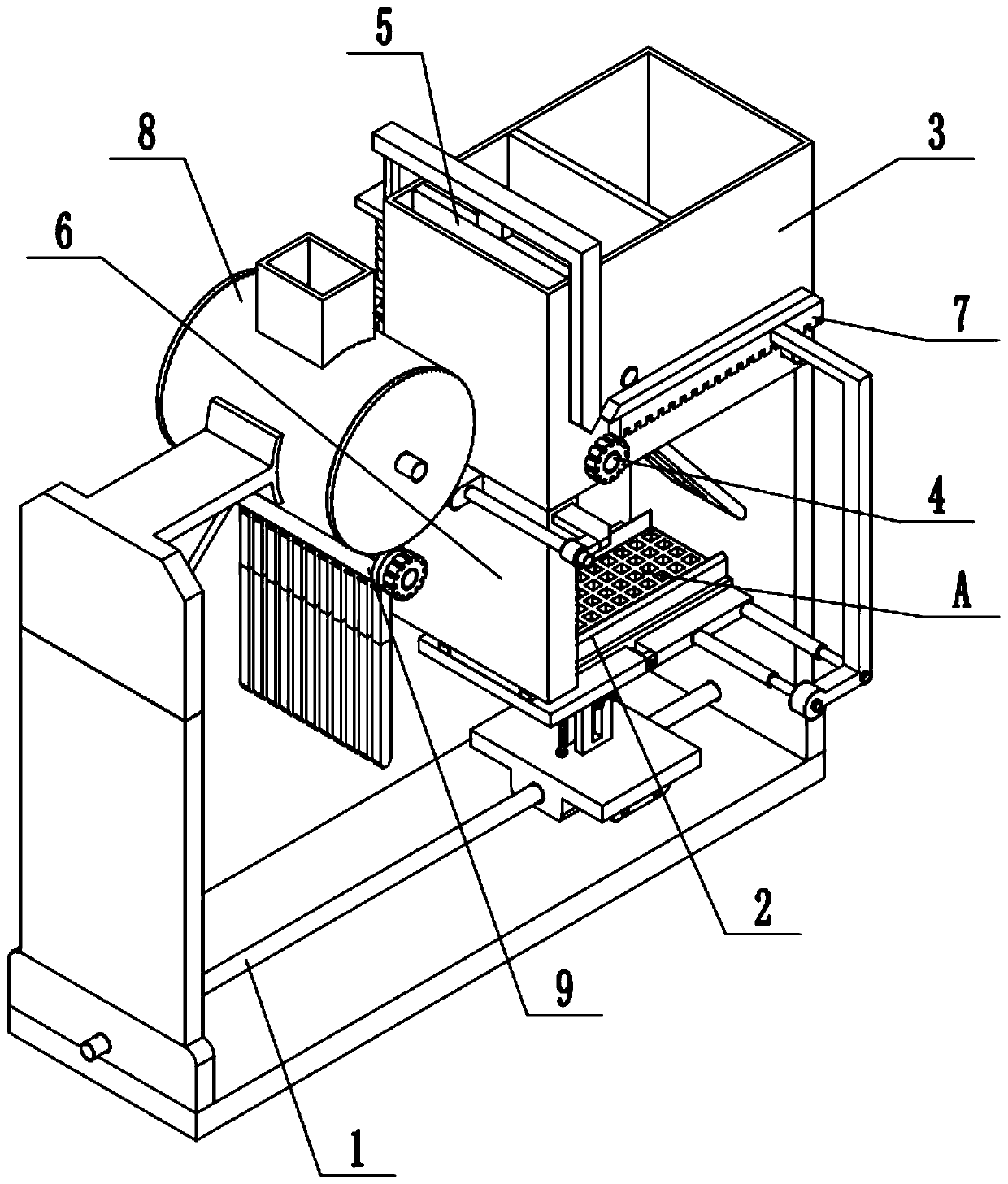

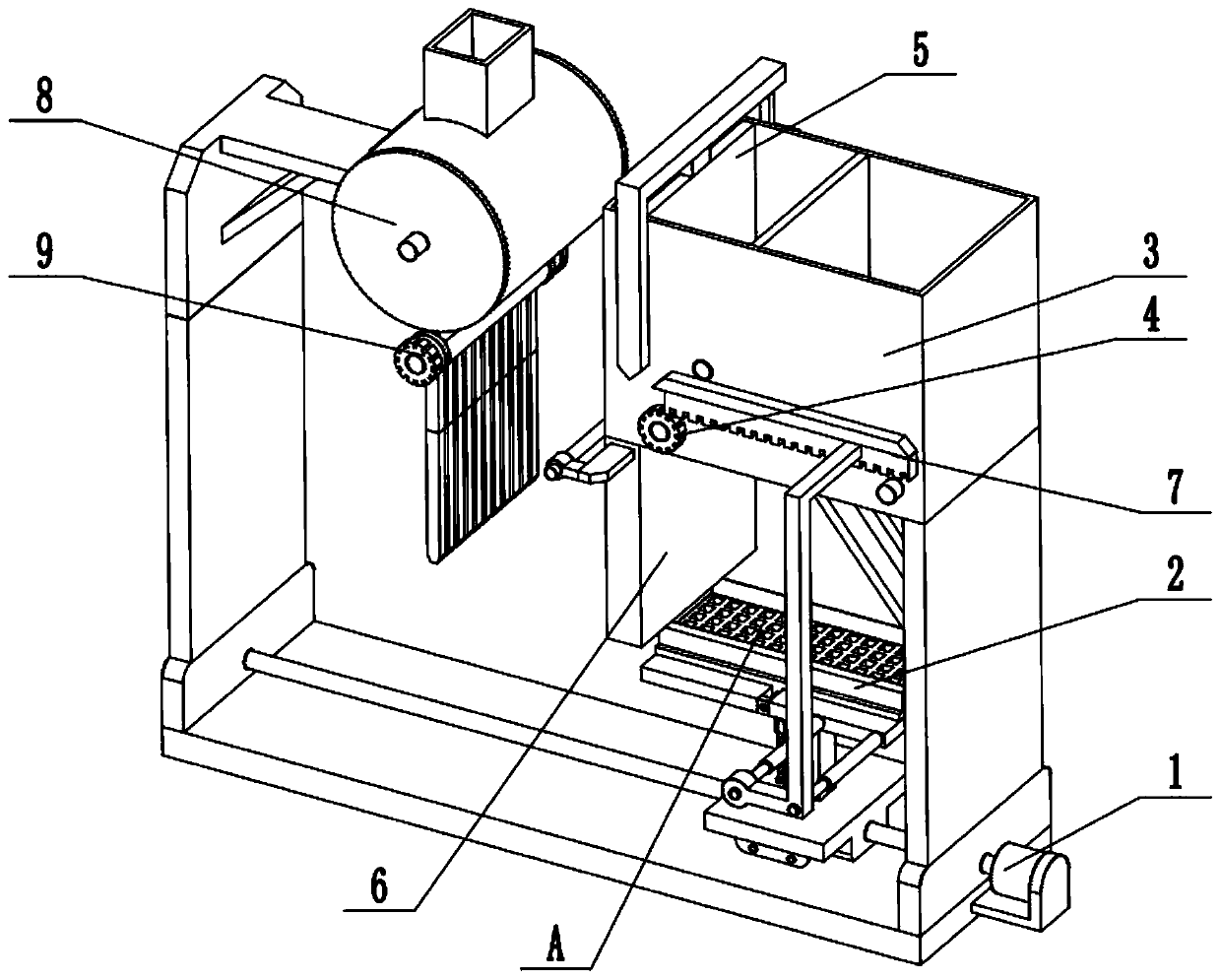

[0040] Attached Figure 1-15 , The multifunctional tobacco seeding system of the present invention includes a driving mechanism 1, a seedling tray fixing mechanism 2, a substrate box 3, a substrate conveying mechanism 4, a substrate blocking door 5, a substrate blanking box 6, a linkage mechanism 7, and a seed storage mechanism 8. The seeder 9 and the frame, the drive mechanism 1 is connected to the lower end of the frame; the drive mechanism 1 is connected to the seedling tray fixing mechanism 2 in transmission; the seedling tray fixing mechanism 2 is slidingly fitted on the frame; The substrate box 3 and the seed storage mechanism 8 are respectively fixed at the front and rear ends of the frame; the substrate box 3 is rotatably connected with the substrate transport mechanism 4; the substrate blocking door 5 is connected to the substrate box 3, and the substrate blocking door 5 Located at the rear end of the substrate conveying mechanism 4; the rear end of the bottom surface ...

specific Embodiment approach 2

[0042] Attached Figure 1-15 , The driving mechanism 1 includes a servo motor 11 with a reducer and a lead screw 12; the servo motor 11 is fixed on the frame; the motor shaft of the servo motor 11 is in transmission connection with the lead screw 12; the lead screw The two ends of 12 are respectively rotatably fitted to the front and rear ends of the frame. After the servo motor 11 inside the driving mechanism 1 is powered on, it can drive the lead screw 12 to rotate. When the lead screw 12 rotates, it can drive the seedling tray fixing mechanism 2 to perform a horizontal displacement movement in the front and rear direction on the frame.

specific Embodiment approach 3

[0044] Attached Figure 1-15 The seedling tray fixing mechanism 2 includes a supporting plate 21, a supporting frame 22, a sliding seat 23, a T-shaped lifting seat 24, an adjusting wheel 25, an adjusting screw 26, a push-pull rod 27, a push-pull seat 28, a horizontal shaft 29, a clamp Tightening plate 210 and walking wheel 211; the middle of the bottom end of the supporting plate 21 is fixed on the sliding seat 23 through two support frames 22; the sliding seat 23 is slidingly fitted on the frame; the sliding seat 23 is fitted with threads In the middle of the lead screw 12; the two sides of the lower end of the sliding seat 23 are respectively connected with two traveling wheels 211; the wheel surface of the traveling wheel 211 is roll-fitted on the frame; the adjusting wheel 25 is fixed on the adjusting screw 26 The middle end of the adjusting screw 26 is threadedly fitted on the T-shaped lifting seat 24, and the T-shaped lifting seat 24 is slidably fitted in the longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com