Strengthening method and strengthening composition for lithium-containing white ceramic glass

A technology for white ceramics and glass, applied in the field of chemical strengthening process of white ceramic glass, can solve the problems of increasing the life of molten salt, unfavorable strengthening, and inconspicuousness, and achieve the effects of improving production efficiency, reducing production costs, and improving lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

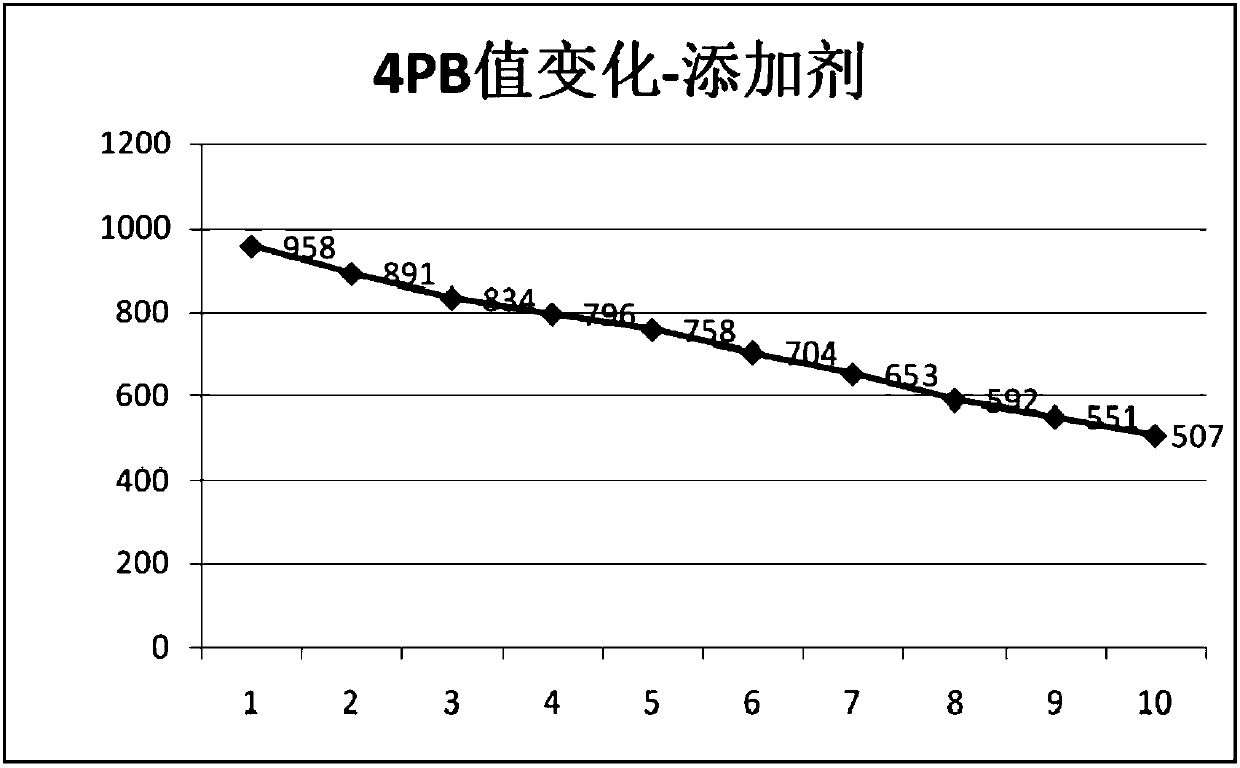

[0026] Such as figure 2 Shown, the present invention provides a kind of strengthening method of Lithium-containing white ceramic glass, comprises using by NaNO 3 The molten salt of the composition is used to treat the lithium-containing white ceramic glass. The method also includes adding additives including sodium carbonate and a special adsorbent to the molten salt at a temperature of 430° C., allowing the reaction to stand for more than 2 hours, and then adding Strengthened white ceramic glass, the special adsorbent is one or more selected from metasilicate, diatomaceous earth and alumina, and the additive dosage is the weight ratio of the molten salt, sodium carbonate and special adsorbent It is 100:1~2:0.2~0.5.

[0027] In a specific embodiment, the strengthening temperature of the lithium-containing white ceramic glass is 420-450° C., and the strengthening time of each furnace of the lithium-containing white ceramic glass is 5-9 hours.

[0028] Specifically, the addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com