A centrifugal spinning system for sheath-core fiber

A technology of skin-core fiber and leather material, which is applied in the centrifugal spinning system and the field of centrifugal spinning, and can solve the problems that the skin-core structure spinning fiber cannot be produced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

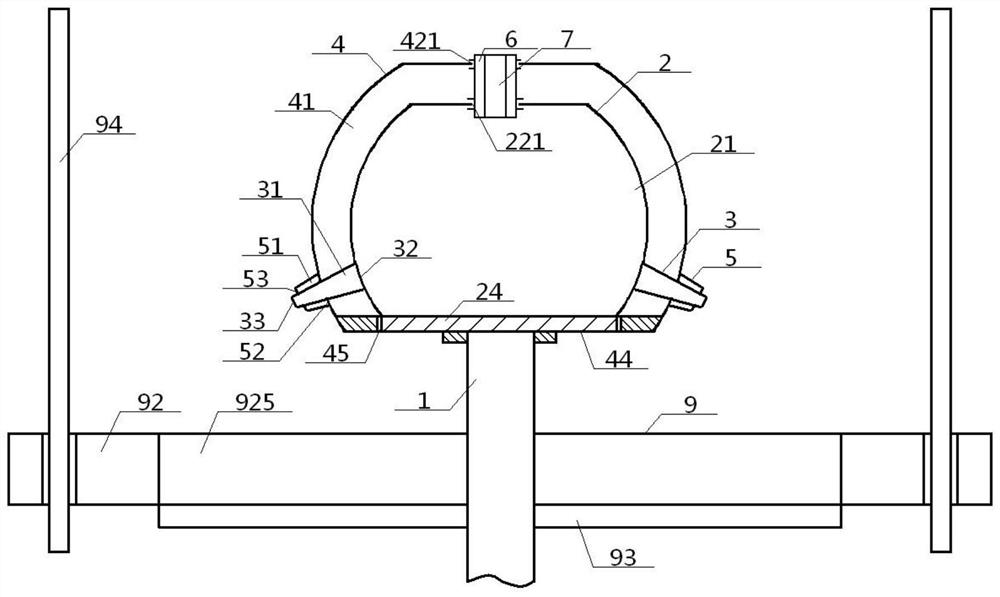

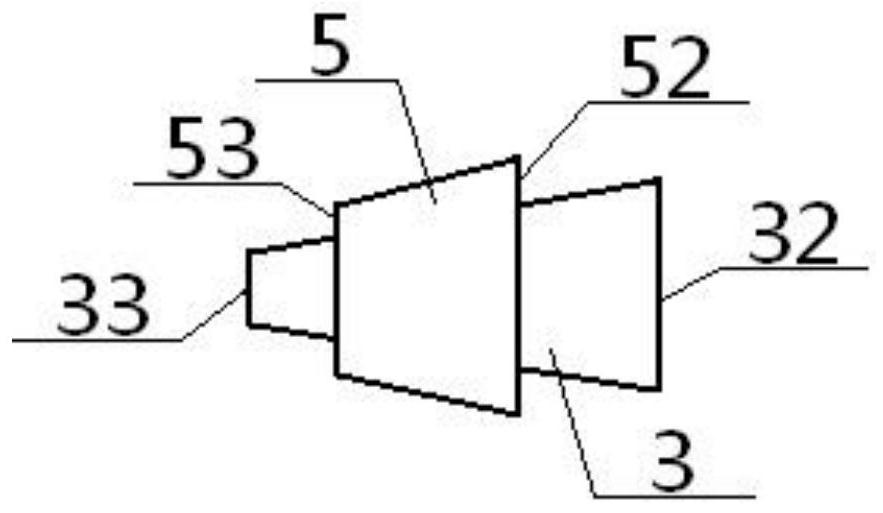

[0058] see figure 1 - Figure 11 , a centrifugal spinning system for sheath-core fibers, comprising a core rotating container 2, a core injection pipe 3 and a collecting device 9, the core rotating container 2 is surrounded by a collecting device 9, and the inside of the core rotating container 2 is provided with a core Material cavity 21, the inside of core injection pipe 3 is provided with core tube cavity 31, and core material cavity 21 communicates with core outlet 33 after passing through core inlet 32, core tube cavity 31 successively, and core inlet 32 is connected with the side wall of core rotating container 2 connected, and the core outlet 33 is located inside the collection device 9; the centrifugal spinning system also includes the skin rotating container 4 and the skin injection pipe 5, and the collection device 9 includes a ventilation ring disk 92, a bottom concave disk 93 and four collecting Rod 94, the ventilation ring plate 92 includes a top ring plate sur...

Embodiment 2

[0060] Basic content is the same as embodiment 1, the difference is:

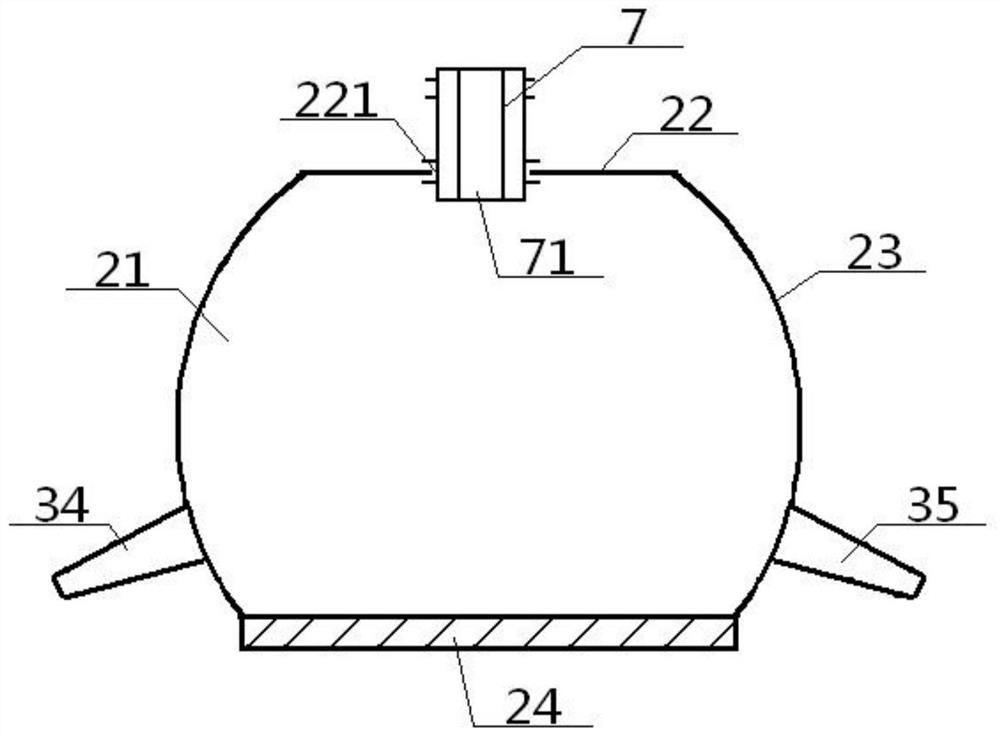

[0061] The leather rotating container 4 comprises a leather top plate 42, a leather ball circumference 43 and a leather bottom 44, the bottom surface of the leather bottom 44 is connected with the top of the rotating rod 1, and the middle part of the leather bottom 44 is provided with a leather Groove 45, the peripheries of the top surface of leather device bottom layer 44 are connected with the periphery of leather device top plate 42 through skin device ball circumference 43, and leather device top plate 42, leather device bottom plate 44 are mutually parallel up and down; Described core rotating container 2 comprises Core device top plate 22, core device spherical circumference 23 and core device bottom layer 24, described core device top plate 22 and core device bottom layer 24 are parallel to each other up and down, and the periphery of core device top plate 22 passes the top of core device spherical ci...

Embodiment 3

[0063] Basic content is the same as embodiment 1, the difference is:

[0064]The top ring disk surface 921 is provided with four top arc surface areas 9211 uniformly arranged along the same circumference, and a top arc surface area 9212 is sandwiched between adjacent top arc surface areas 9211, and each top arc surface area 9211 Both are provided with a plurality of top air holes 9213, and the bottom ring surface 923 is provided with four bottom arcuate areas 9231 evenly arranged along the same circumference, and a bottom notch area 9232 is sandwiched between adjacent bottom arcuate areas 9231 , each bottom arc surface area 9231 is provided with a plurality of bottom air holes 9233, the bottom air holes 9233 correspond to the top air holes 9213 one by one, the bottom missing surface area 9232 corresponds to the top arc surface area 9211, and the bottom missing surface area The bottom socket 952 provided in 9232 corresponds to the top socket 951 provided in the top arc surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com