Cheese spinning and drying machine

A drying machine and package yarn technology, which is applied in textiles and papermaking, textile material treatment, removal of liquid/gas/steam, etc., can solve problems such as uneven dyeing and low drying efficiency, and achieve improved drying efficiency, The effect of improving production quality and speeding up drying work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

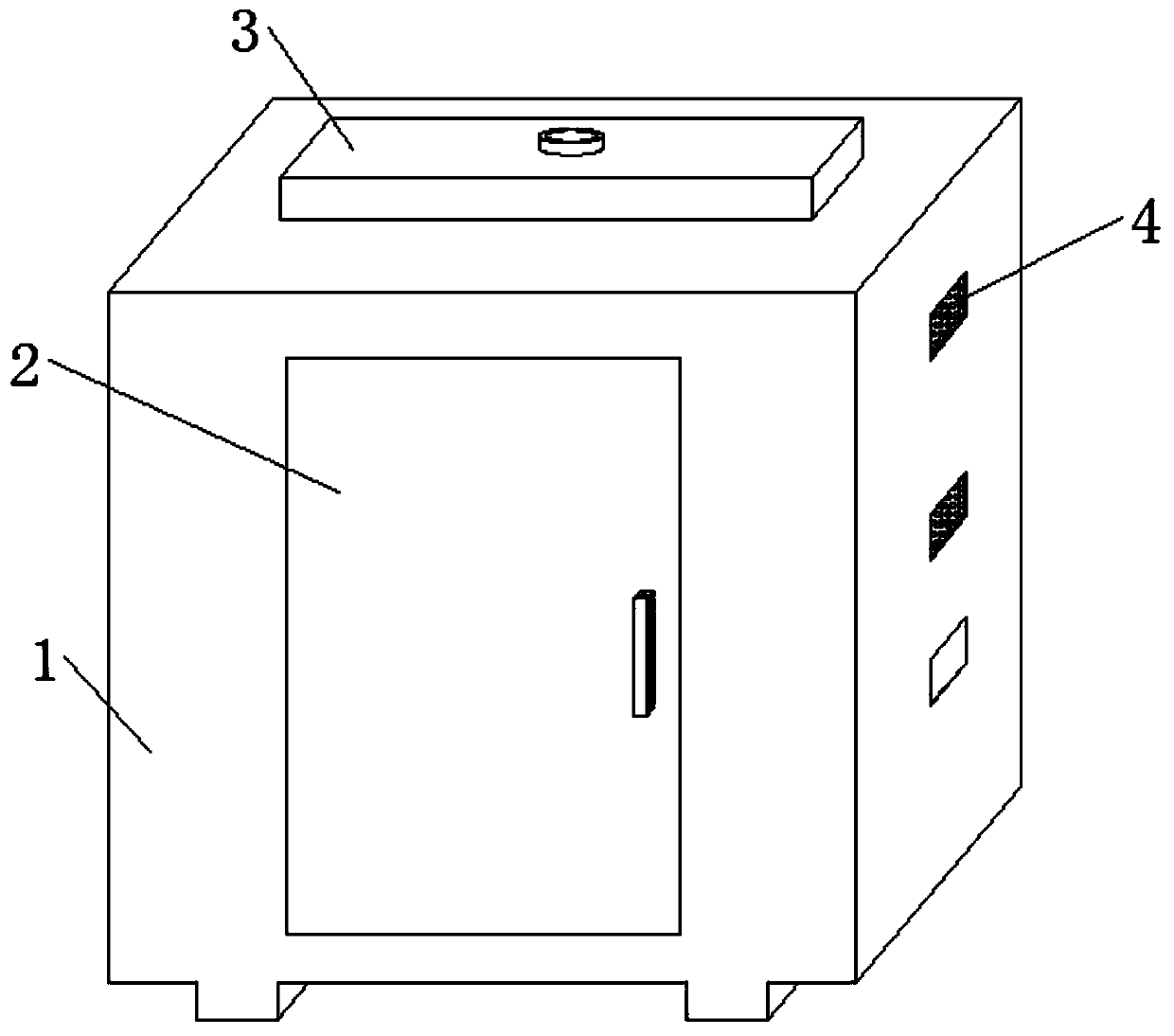

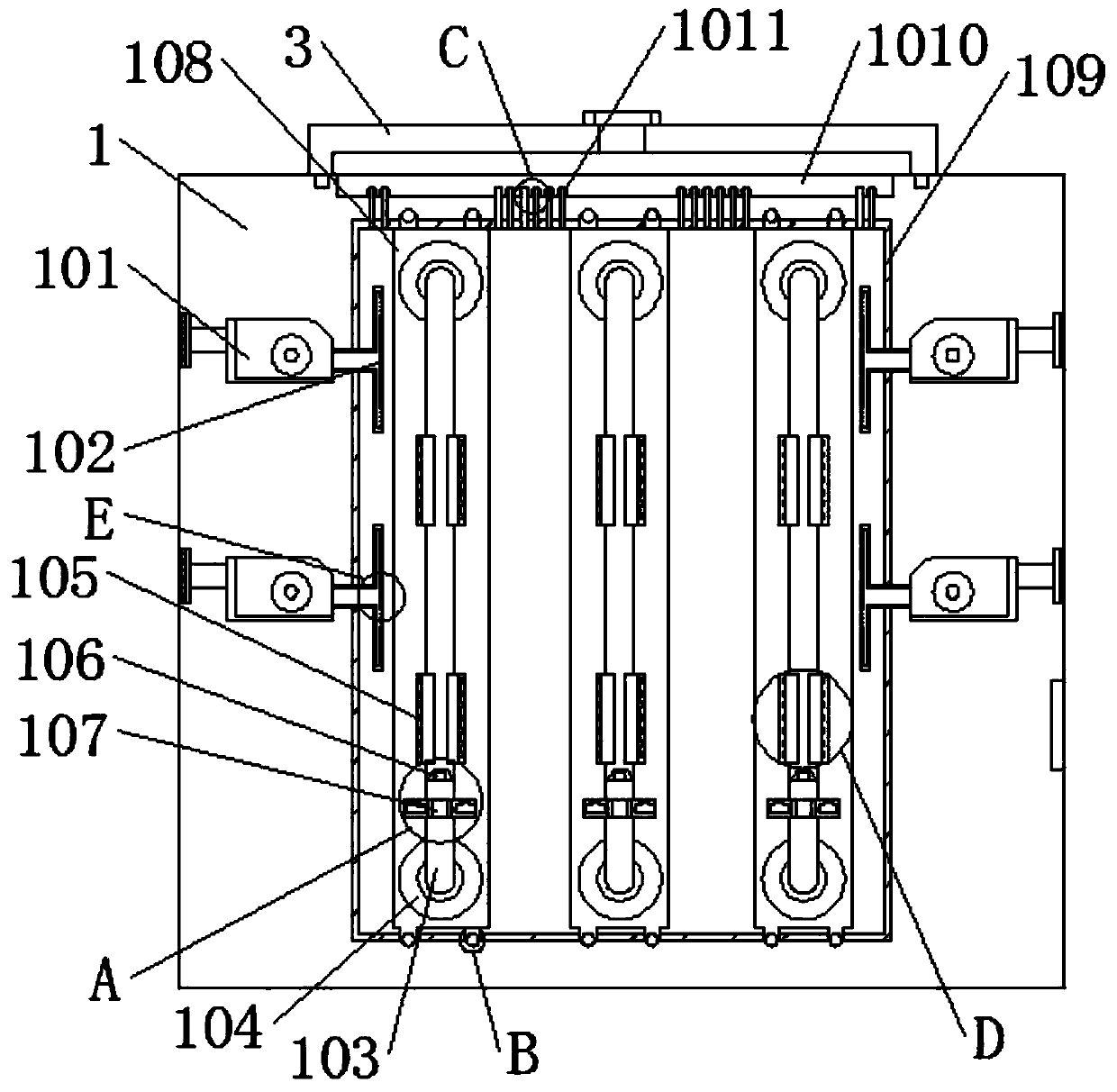

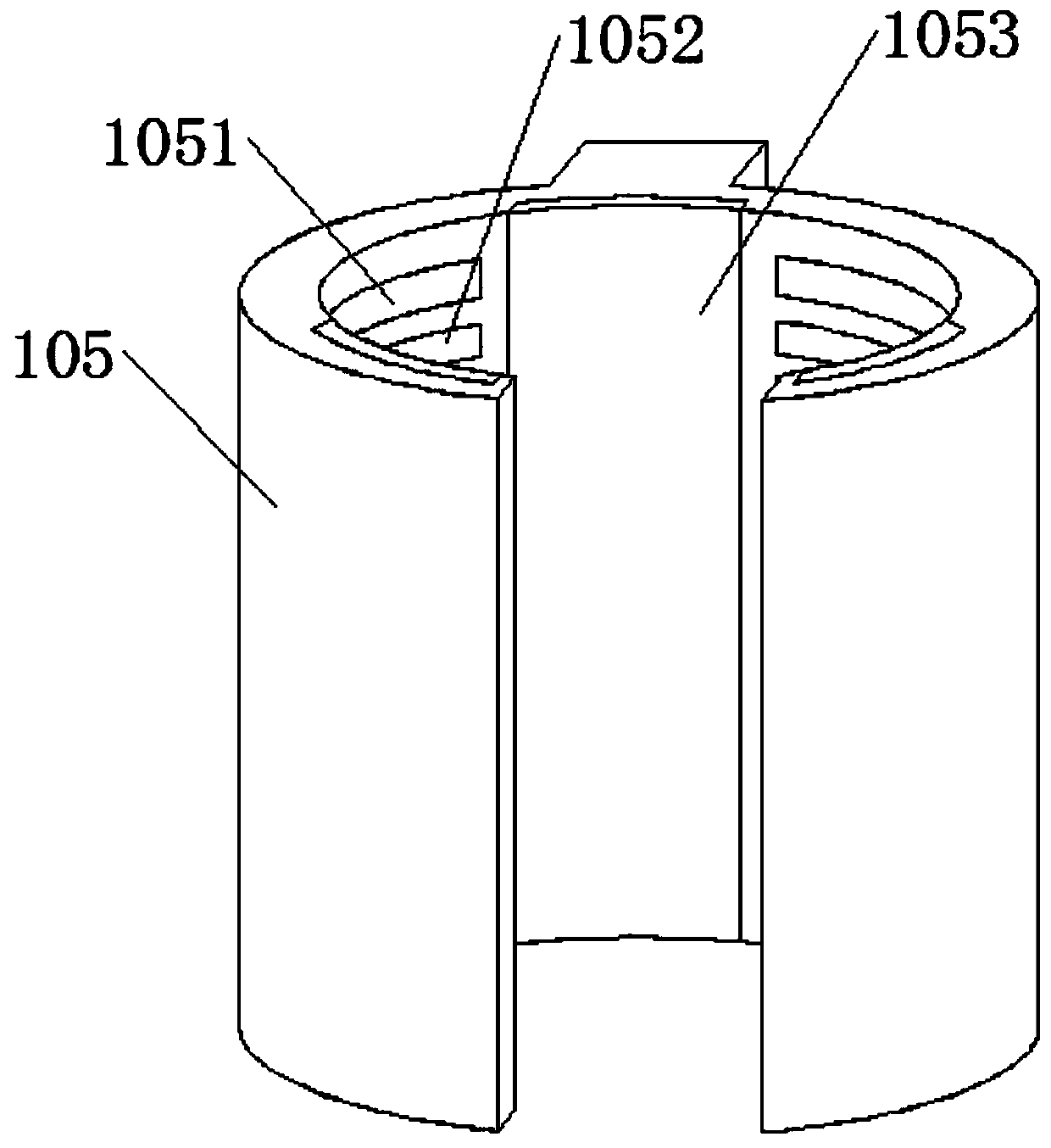

[0031] See attached figure 1 to attach Figure 11 , a cheese textile dryer, including: a housing 1, a hot air blower 101, an air outlet plate 102, an air outlet 1021, a central axis 103, a runner 104, a drying column 105, a heating plate 1051, and an arc mirror 1052, one-way mirror 1053, windshield column 106, hair brush 1061, smoothing plate 107, absorbent cotton ring 1071, feed port 1072, collection chamber 1073, sliding column 108, bottom wheel 1081, insulation layer 109, liquid collection Groove 1010, air guide pipe 1011, door body 2, steam suction top cover 3 and air guide hole 4, door body 2 is movably connected to the middle part of the front end of shell 1, and the top of shell 1 is provided with suction steam top cover 3, and the left and right sides of shell 1 Air guide holes 4 are embedded in the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com