Method of improving power saving efficiency of anomalous hall effect coating material

A technology of abnormal Hall effect and coating material, which is applied in the direction of temperature control, electrical components, switching devices, etc. by electric means, to achieve the effect of reducing cost and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

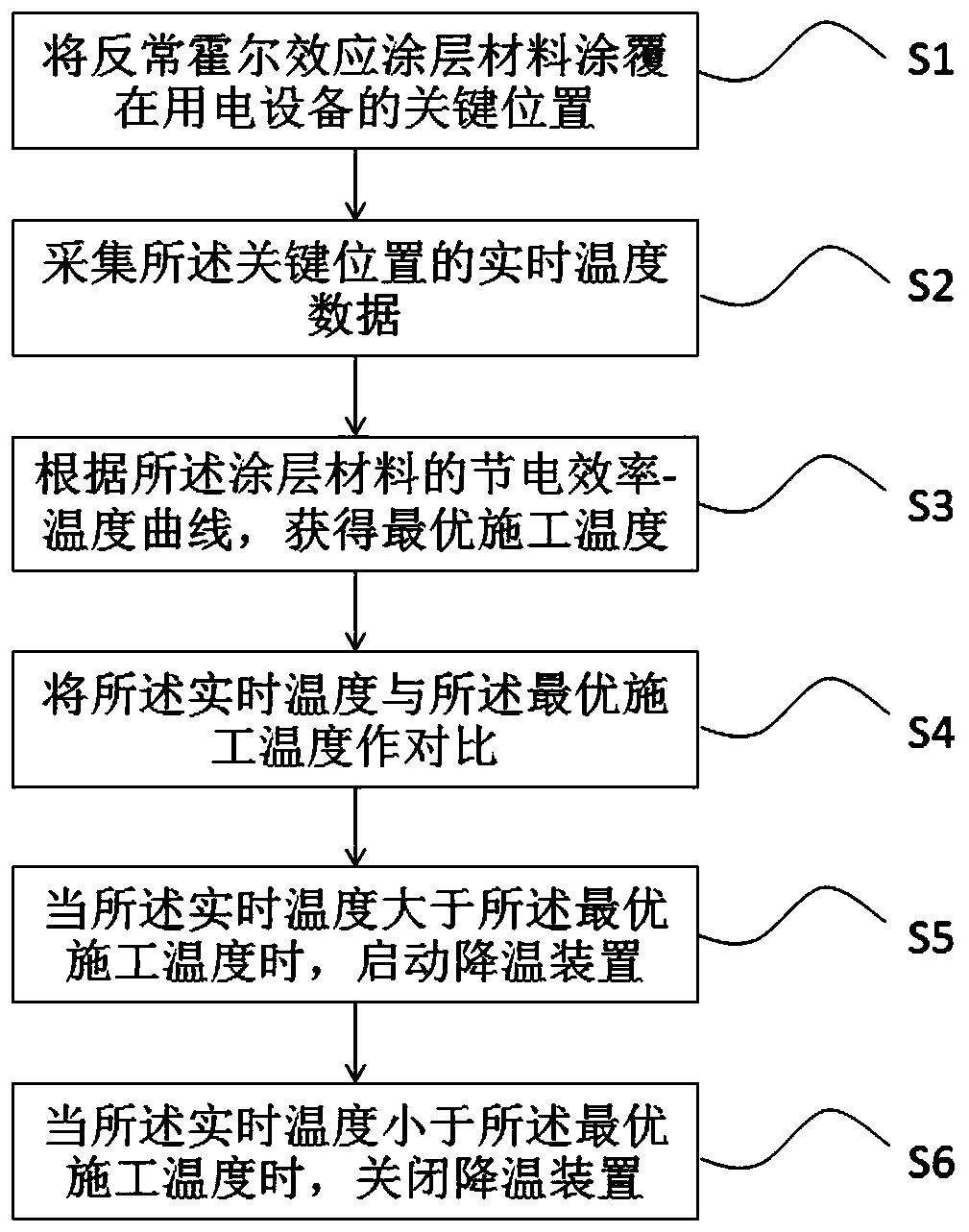

[0032] Such as Figure 1-3 As shown, a method for improving the power-saving efficiency of anomalous Hall effect coating materials comprises the following steps:

[0033] S1. Coating the abnormal Hall effect coating material on the key position of the electrical equipment, the electrical equipment is a power distribution cabinet; it can be determined by the control variable method, coating the coating material on the inner surface of the power distribution cabinet In terms of power saving per unit time, the power saving effect is the best, so the key position is determined to be the inner surface of the power distribution cabinet.

[0034] S2. Collect the real-time temperature data of the inner surface of the power distribution cabinet, which is 45 degrees Celsius;

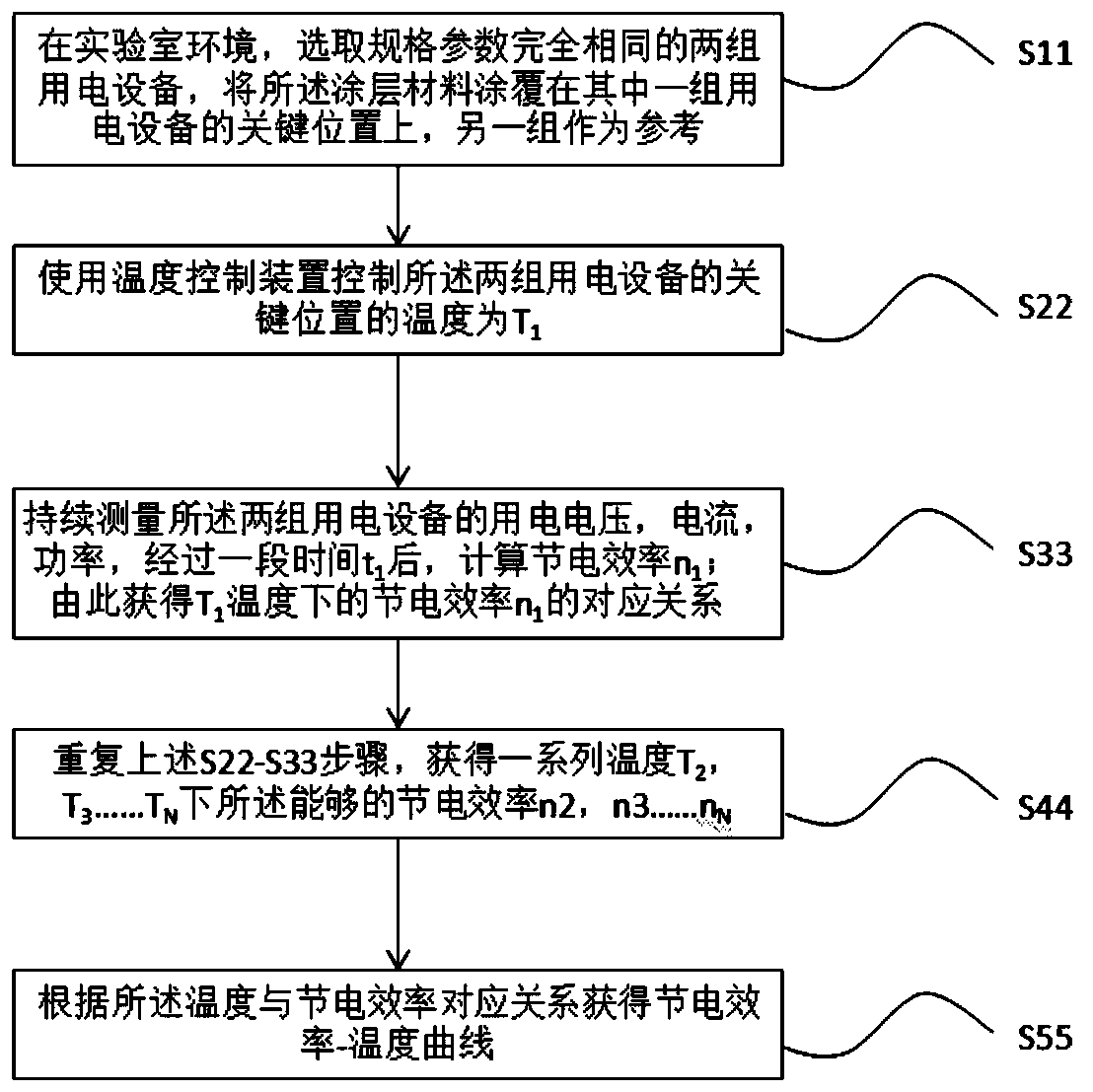

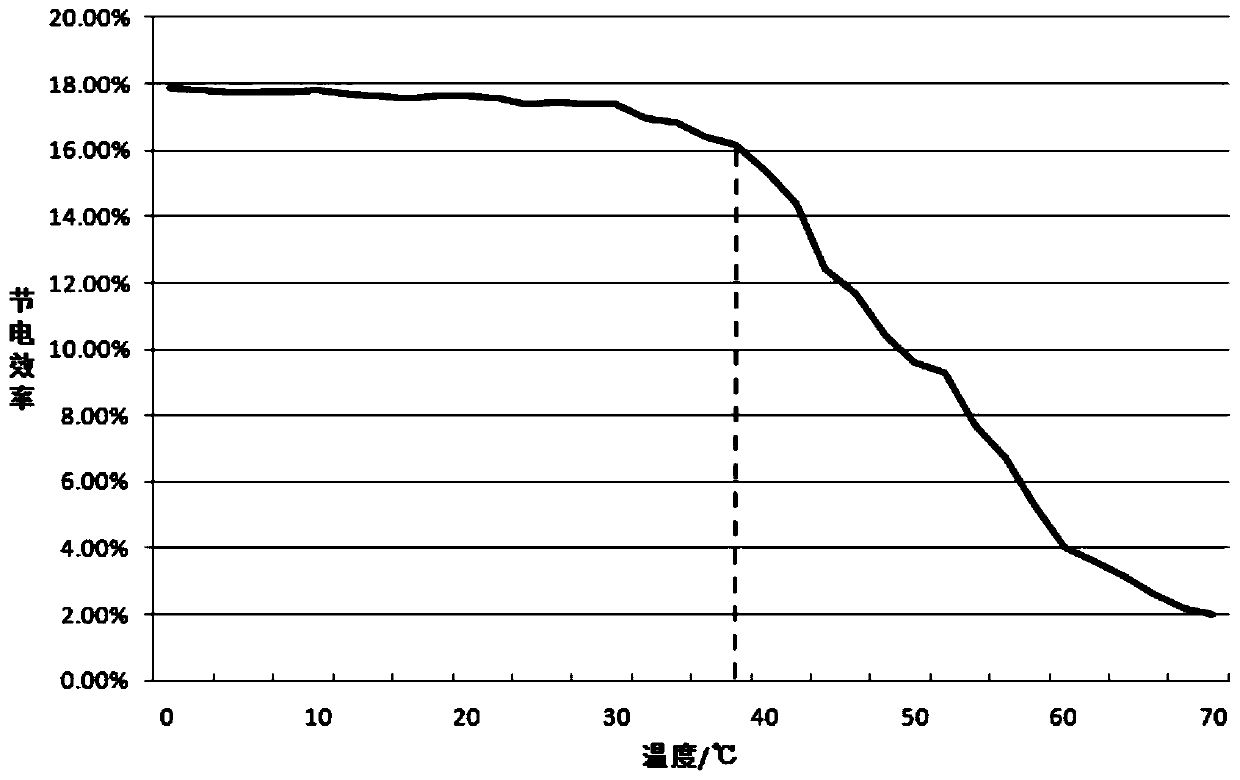

[0035] S3. Obtain the optimal construction temperature according to the power-saving efficiency-temperature curve of the coating material; wherein, the efficiency-temperature curve of the coating material is obta...

Embodiment 2

[0046] Such as Figure 1-2 , shown in 4, a method for improving the power-saving efficiency of anomalous Hall effect coating materials comprises the following steps:

[0047]S1. Coating the abnormal Hall effect coating material on the key position of the electrical equipment, the electrical equipment is a motor; it can be determined by the control variable method, the coating material is coated on the inner surface of the motor cover, the unit The power saving within the time period is the largest and the power saving effect is the best, so the key position is determined to be the inner surface of the motor cover.

[0048] S2. Collect the real-time temperature data of the inner surface of the motor cover, which is 48 degrees Celsius;

[0049] S3. Obtain the optimal construction temperature according to the power-saving efficiency-temperature curve of the coating material; wherein, the efficiency-temperature curve of the coating material is obtained through the following steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com