Method for manufacturing composition of fermented soybean products and composition of fermented soybean products manufactured thereby

A composition and technology of soybean paste, which are applied in the fields of food science, food preservation, food ingredients as viscosity modifiers, etc. Exchange efficiency, improve storage, and the effect of clear and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] [Example 1: Preparation of sauces]

[0045] In order to demonstrate the quality and variation of the preparation effect of the sterilization method of the present disclosure, sauces were prepared using chili paste, soybean paste, seasoned soybean paste, and paste-based sauces as raw materials. Specifically, in the step of adding water, for chili sauce, 5 to 15 parts by weight of purified water is added to 100 parts by weight of chili sauce; and for soybean paste, relative to 100 parts by weight of soybean paste, 2 to 10 parts by weight of purified water are added; and for the seasoned soybean paste, 1 to 10 parts by weight of purified water is added with respect to 100 parts by weight of the seasoned soybean paste. A paste-based sauce is prepared by mixing 50% to 60% by weight of soybean paste with 1% to 10% of anchovy / kelp extract and 30% to 40% of purified water. The sauce added with water is chopped into a size of 1 mm to 3 mm and preheated to 60° C., and then steri...

experiment example 1

[0068] Experimental Example 1: Determination of Water Content in Chili Sauce, Soybean Paste and Seasoned Soybean Paste

[0069] The water content in the raw material (paste) before adding water was measured by the normal-pressure drying method. Specifically, the sauce was dried by heating at 105° C. to 110° C. until the sauce sample reached a constant weight, and the reduced weight was determined as the water content. The measurement results were as follows: chili paste contained 39.4% by weight of water, soybean paste contained 48.9% by weight of water, and seasoned soybean paste contained 46.8% by weight of water.

experiment example 2

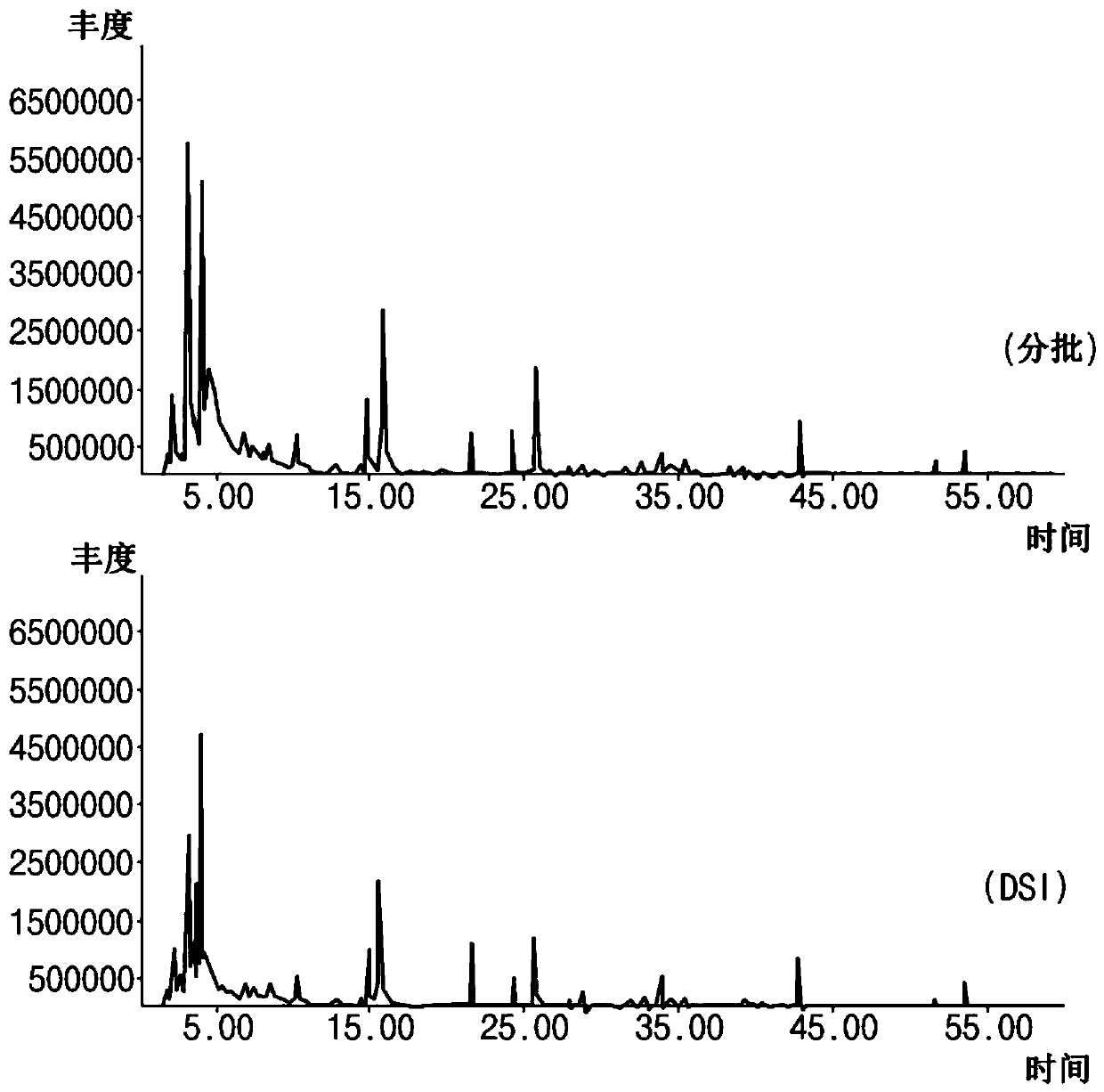

[0070] Experimental Example 2: Analysis of Volatile Flavor Components of Chili Sauce Prepared by the Method of the Disclosure

[0071]The volatile flavor components in the chili sauce prepared by the direct steam injection sterilization method of embodiment 1 and the chili sauce prepared by the batch sterilization method of comparative example 1 are analyzed, and the comparative results are shown in figure 1 middle.

[0072] In both products prepared by direct steam injection sterilization and those prepared by batch sterilization methods, ethanol accounts for the vast majority of alcohols, followed by 3-methyl-1-butanol and 2-methyl- 1-butanol. Specifically, 1-hexanol and 1-octen-3-ol, flavor compounds known to be contained in representative soybean odors, were detected only in chili pastes prepared by the batch sterilization method, whereas 2-Methylbutyraldehyde and 3-Methylbutyraldehyde (which are Maillard intermediates produced by the Strekel aldehyde Maillard reaction)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com