Method for preparing fine aggregate with construction waste and application of fine aggregate

A construction waste and fine aggregate technology, applied in applications, household utensils, ceramic products, etc., can solve problems such as unsatisfactory production needs, high production costs, and complicated processes, and achieve low cost, extended service life, and simple equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

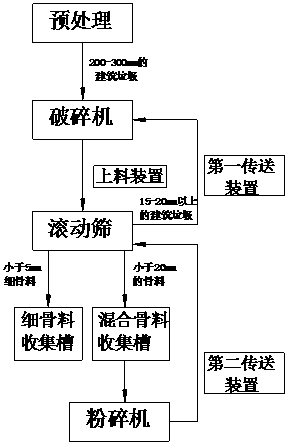

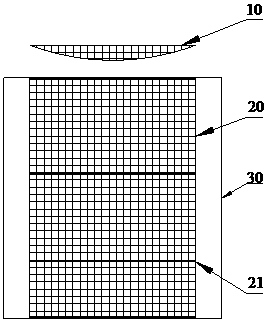

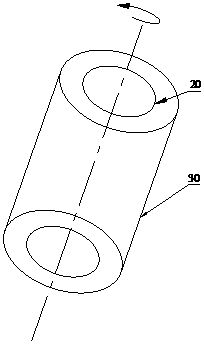

[0033] The method provided by the invention prepares fine aggregate with construction waste, such as figure 1 As shown, it mainly includes the crushing step: use a crusher to crush the construction waste to obtain broken construction waste below 35mm; cycle screening step: the broken construction waste is sent to the rolling screen inclined on the bottom surface through the feeding device for secondary grade screening, such as figure 2 and image 3 As shown, the rolling screen includes an end cover 10 for the first stage of screening, a drum 20 affixed to the bottom of the end cover 10 for the second stage of screening, a casing 30 arranged outside the drum and used for driving The driving device (not shown) for the rotation of the rolling screen, the end cover 10 has an arc surface structure with the middle part concave toward the direction of the drum 20 and is composed of a grid-like screen with a grid side length of 15-20mm; the drum 20 is formed by winding a grid-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com