Pipe-laying construction method under road surface for fluid heating road snow melting system

A construction method and technology of heating pipes, applied to roads, roads, pavement details, etc., to achieve the effects of shortening the construction period, important economic benefits and social significance, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

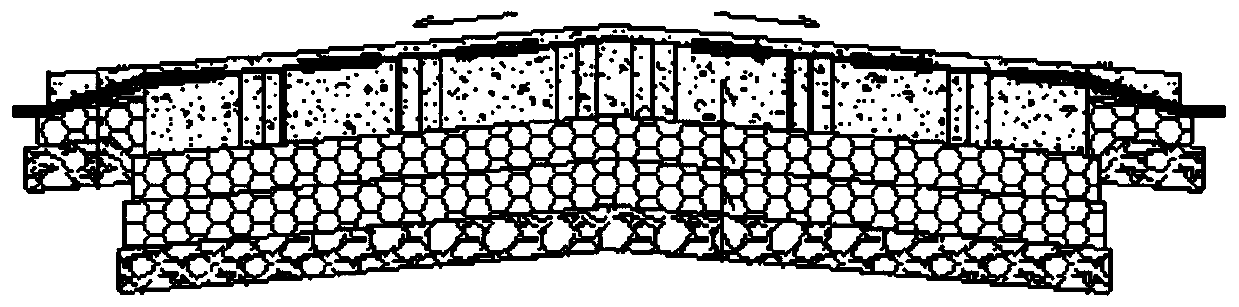

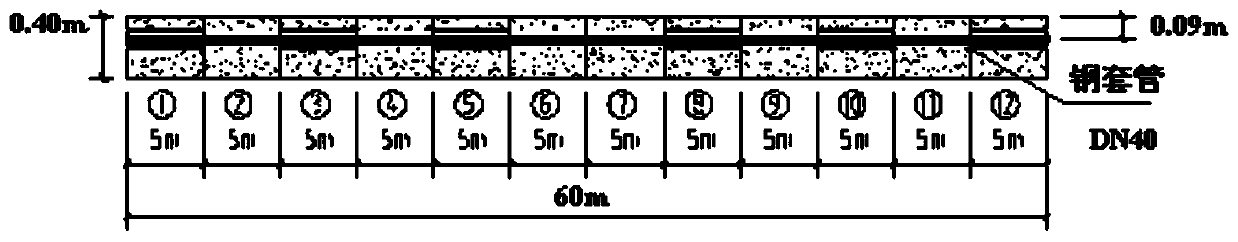

[0036] Take an airport runway as an example. The runway is 60 meters wide. For this runway, fluid heating road snowmelt pipelines should be laid. Because the runway is too wide, construction needs to be skipped. The scheme of the present invention will be introduced in detail below.

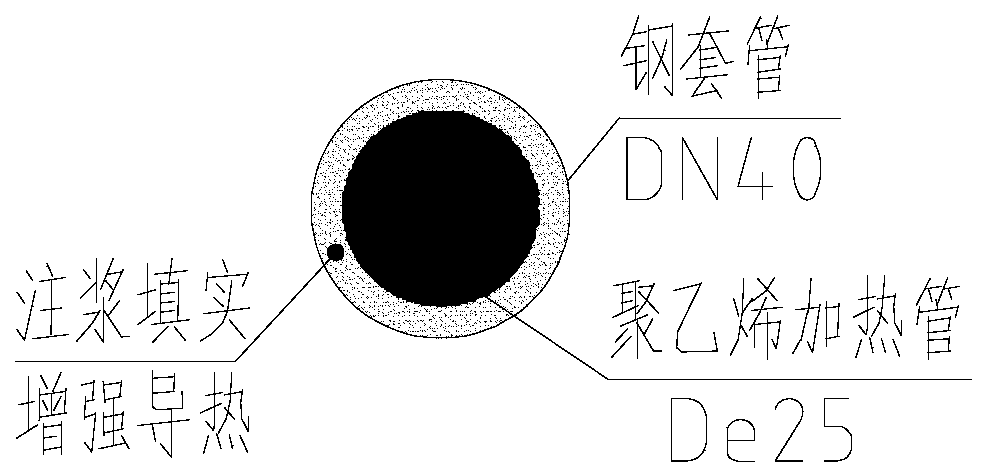

[0037] Figures 1 to 3 For the straight-through piping construction plan that needs to pass through the adjacent concrete warehouse, according to the technical requirements of the runway for airport jump warehouse construction, when pouring concrete on the runway, it is necessary to use 5m wide as a construction warehouse to pour concrete along the taxiing direction of the aircraft, so the entire runway is in When pouring concrete, it is divided into 12 warehouses. At the same time, in order to ensure the construction period, when pouring concrete on the runway, multiple construction warehouses are constructed at intervals at the same time. Therefore, steel sleeves must be installed outside part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com