Flashing type closed heat exchanger

A heat exchanger and flashing technology, applied in the field of flashing closed heat exchangers, can solve the problems of poor cooling effect of heat exchangers, difficulty in meeting the cooling demand, influence of heat exchange effect, etc., and achieve small installed capacity and small space. , The cooling effect is stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

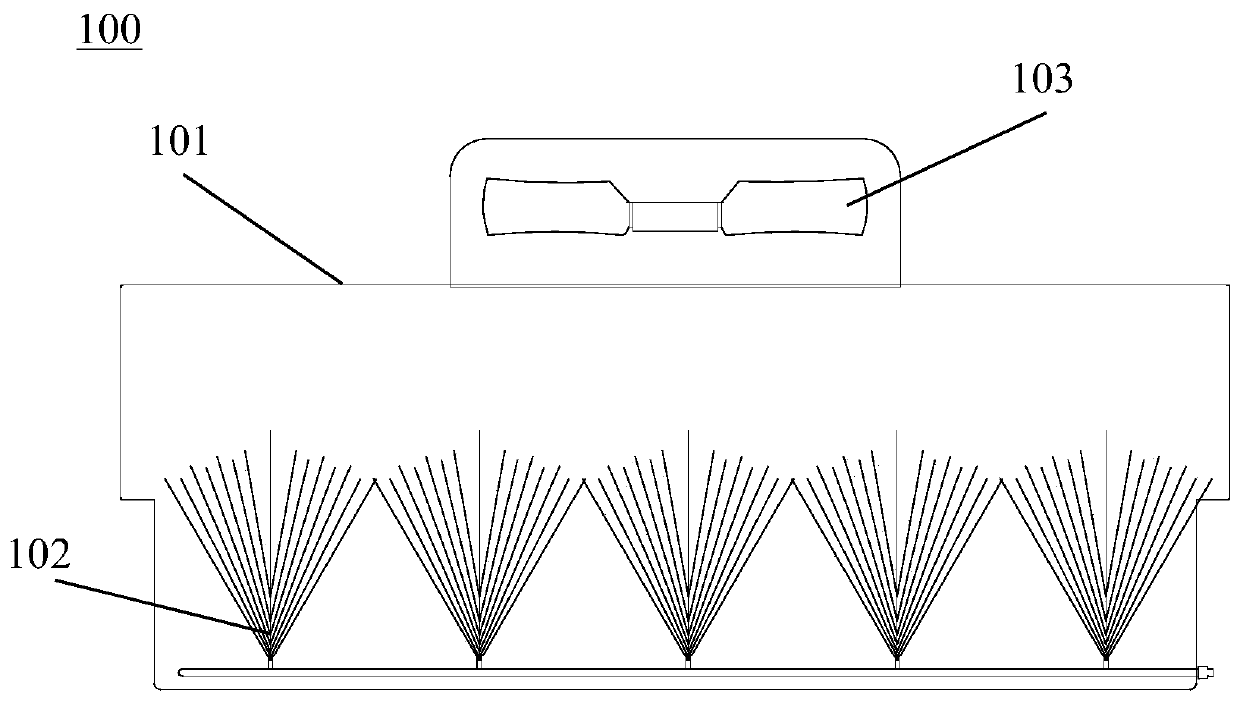

[0044] Such as figure 2 As shown, in Embodiment 1 of the present invention, the flash-type closed heat exchanger includes a closed shell 101, which is rectangular in shape, surrounded by a plate structure, and has an accommodating chamber inside. The bottom of the accommodation chamber is provided with a water atomization device 102, and the water atomization device 102 sprays the atomized water produced into the accommodation chamber from bottom to top; the top of the accommodation chamber is provided with a negative pressure fan 103, and the negative pressure fan 103 Continuously discharge the gas in the closed casing 101 out of the closed casing 101 to form a uniform and stable negative pressure environment in the containing chamber. Preferably, the exhaust air volume of the negative pressure fan 103 is greater than the evaporation of the atomized water in the closed casing 101. On the one hand, the steam in the closed casing 101 can be fully discharged to improve the evap...

Embodiment 2

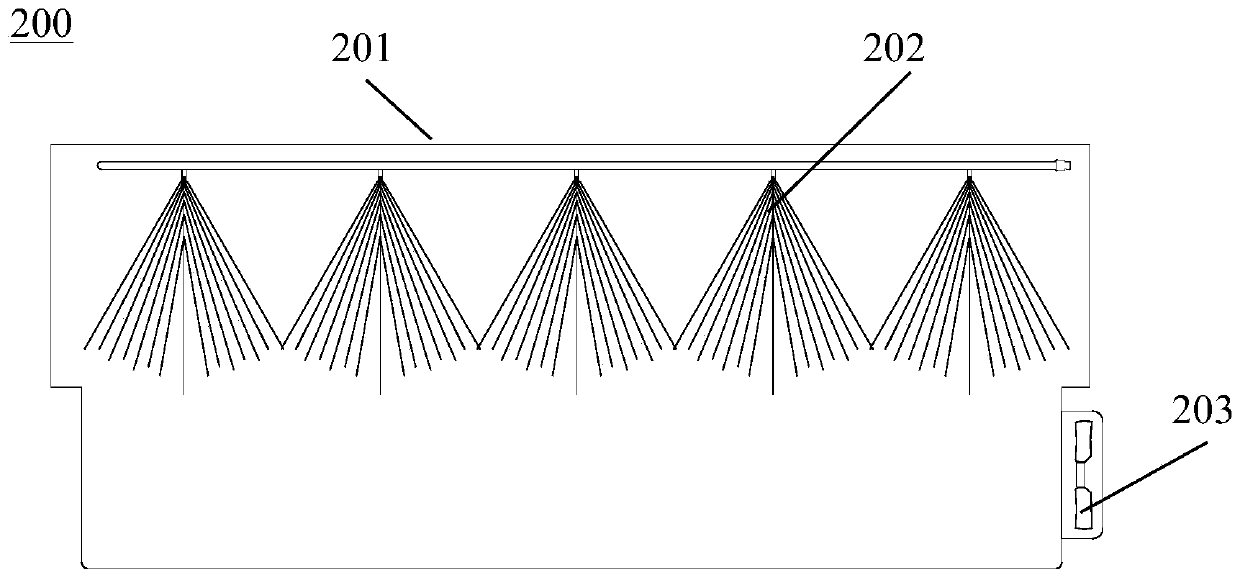

[0048] Such as image 3 As shown, in the second embodiment of the present invention, the flash type closed heat exchanger includes a closed shell 201, which is rectangular in shape, surrounded by a plate structure, and has an accommodating chamber inside. The top of the accommodation chamber is provided with a water atomization device 202, and the water atomization device 202 sprays atomized water into the accommodation chamber from top to bottom; The blower 203, the negative pressure blower 203 continuously discharges the gas in the closed casing 201 out of the closed casing 201, so that a uniform and stable negative pressure environment is formed in the containing chamber. Preferably, the exhaust air volume of the negative pressure fan 203 is greater than the evaporation rate of the atomized water in the closed casing 201. On the one hand, the steam in the closed casing 201 can be fully discharged to improve the evaporation efficiency of the atomized water. On the one hand,...

Embodiment 3

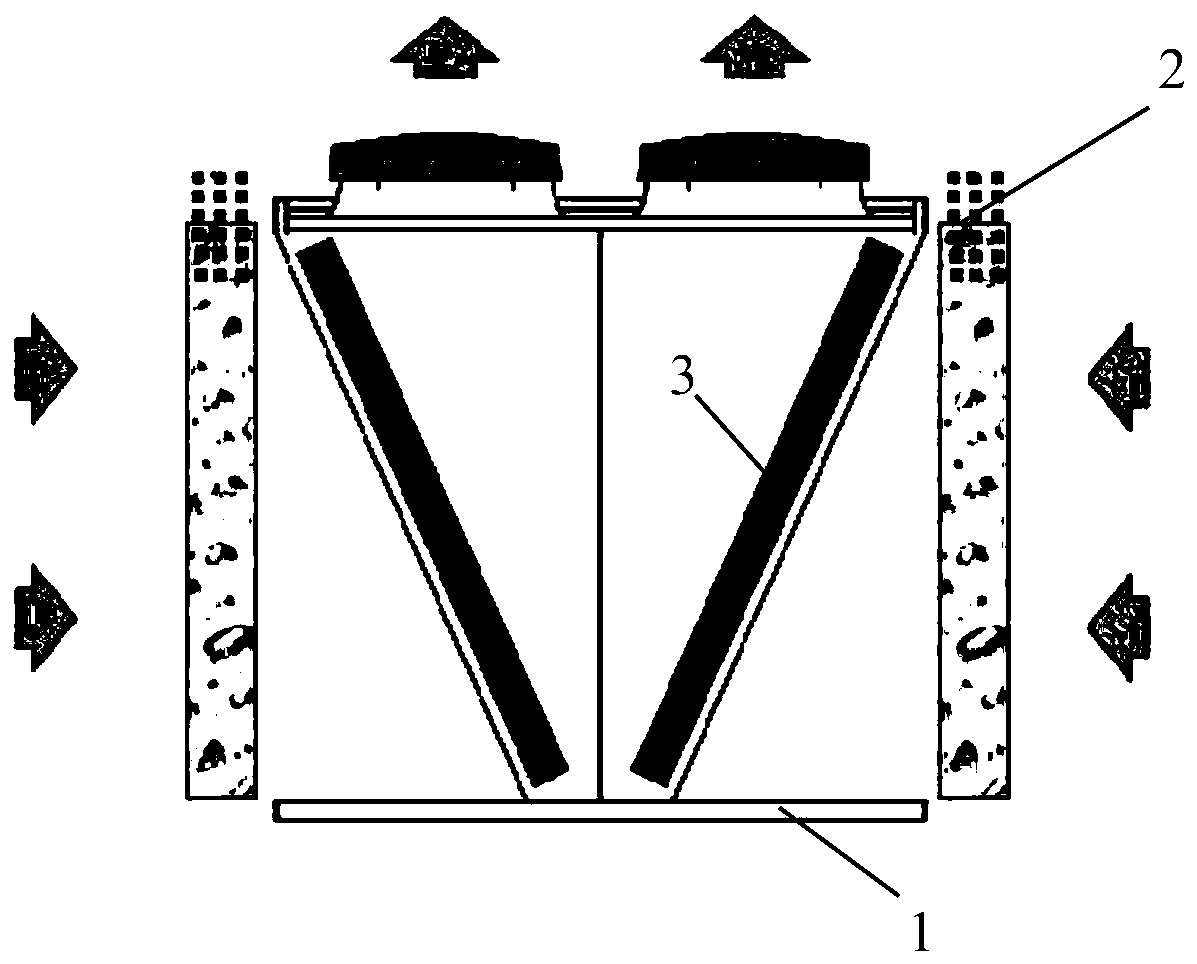

[0056] In Embodiment 3 of the present invention, the flash type closed heat exchanger includes a closed casing 301, one side of the closed casing 301 is provided with a water atomization device 302, and the other side is provided with a negative pressure fan 303, and the closed casing 301 is provided with a water atomization device 302. 301 is equipped with a heat exchange device, the heat exchange device is located between the water atomization device 302 and the negative pressure fan 303, a first static pressure chamber is formed between the negative pressure fan 303 and the heat exchange device, the water atomization device 302 and the heat exchange device A second static pressure chamber is formed between the heating devices, and the negative pressure fan 303 forms a negative pressure environment in the second static pressure chamber, and the water atomization device 302 sprays atomized water into the second static pressure chamber to make the atomization Water evaporates i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com