Air-contained soil pile soil testing device

A test device, soil pile technology, applied in the direction of measuring device, using a stable shear force to test the strength of materials, instruments, etc., can solve the problems of testing, unable to achieve interaction parameters, and unable to accurately determine the gas content of test soil samples , to achieve the effect of accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

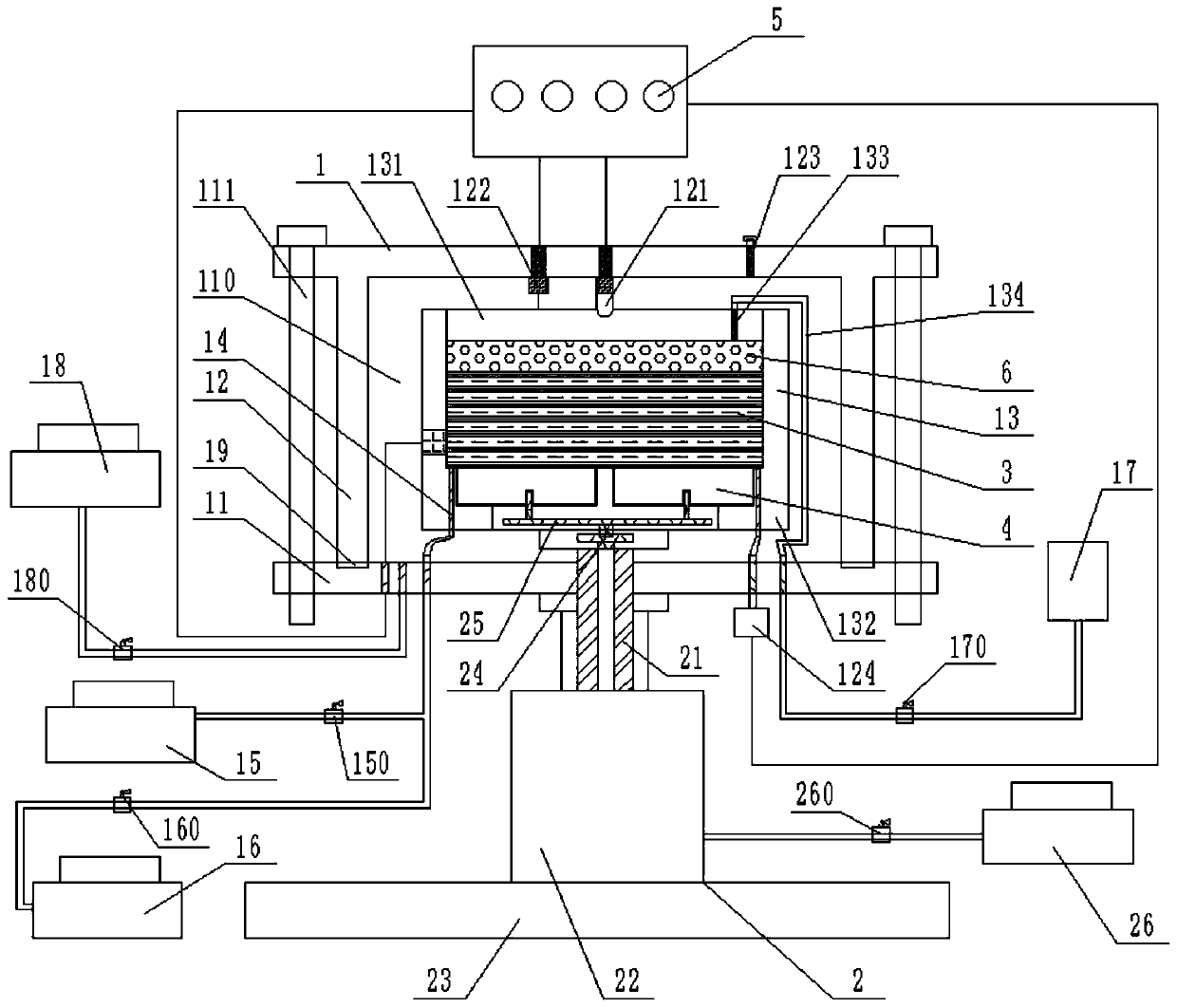

[0057] An air-bearing soil pile-soil test device, including a main controller, a sealed cabin and an axial pressure test device;

[0058] There are test soil samples and prefabricated piles in contact with each other in the sealed cabin; the axial pressure test device extends into the sealed cabin to drive the prefabricated piles and the tested soil samples to perform cyclic shearing motion.

[0059] The airtight cabin includes a bilge, a hatch cover and a test container. The hatch cover is installed on the bilge to form a confining cabin. The test container is located in the confining cabin. Inside the container; a rubber pad is arranged between the hatch bottom and the hatch cover; the hatch cover and the hatch bottom are connected by bolts.

[0060] The axial compression test device includes an axial compression rod, and the axial compression rod passes through the bilge and the test container to drive the prefabricated pile and the test soil sample to perform cyclic sheari...

Embodiment 2

[0076] A method for testing pile soil with air-containing soil, comprising the equipment of Embodiment 1, performing the following steps:

[0077] Step 1. Supplement the vaseline in the rotating chamber, put the prefabricated pile into the test container, make the test soil sample (prefabricated or directly made in the sample container), cover the permeable stone, cover the top cover, and connect the back pressure / Gas discharge pipe; cover the hatch cover, fix the hatch cover to the bilge with bolts, make the pressure sensor and displacement sensor touch the top cover, the sample preparation is completed, close all valves;

[0078] Step 2: Open the confining pressure valve to add water to the confining pressure cabin until water overflows from the overflow port / valve of the hatch cover, close it, and connect the confining pressure pump; open the back pressure valve, and use the back pressure pump to inject water into the test soil sample, Open the valve to remove the gas in t...

Embodiment 3

[0085] A kind of preparation method of air-bearing soil, comprises the equipment of embodiment one, carries out following steps:

[0086] Step 11. Supplement the vaseline in the rotating chamber, put the prefabricated pile into the test container, make the test soil sample (prefabricated or directly made in the sample container), cover the permeable stone, cover the top cover, and connect the back pressure / gas discharge pipe; cover the hatch, bolt the hatch to the bilge so that the pressure sensor and displacement sensor touch the top cover, sample preparation is complete, close all valves;

[0087] Step 12. Open the confining pressure valve and add water to the confining pressure cabin until water overflows from the overflow port / valve of the hatch cover, close it, and connect the confining pressure pump; open the back pressure valve, and use the back pressure pump to inject water into the test soil sample , open the valve, and remove the gas in the test soil sample until wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com