Experimental system for detecting broken wire of wire rope of hoist and detecting method thereof

An experimental system, steel wire rope technology, applied in elevators, transportation and packaging, material magnetic variables, etc., can solve problems such as low degree of automation, large volume, and low detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be further described below in conjunction with accompanying drawing.

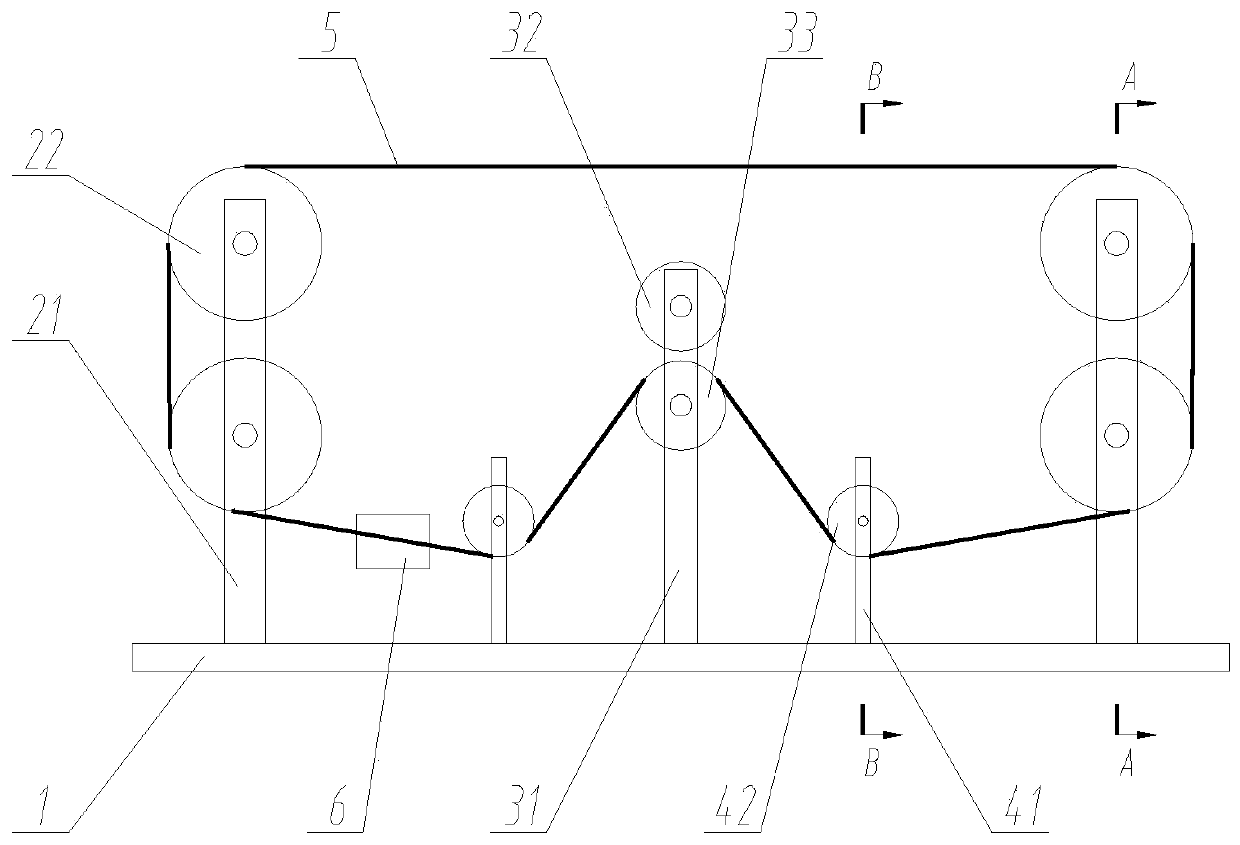

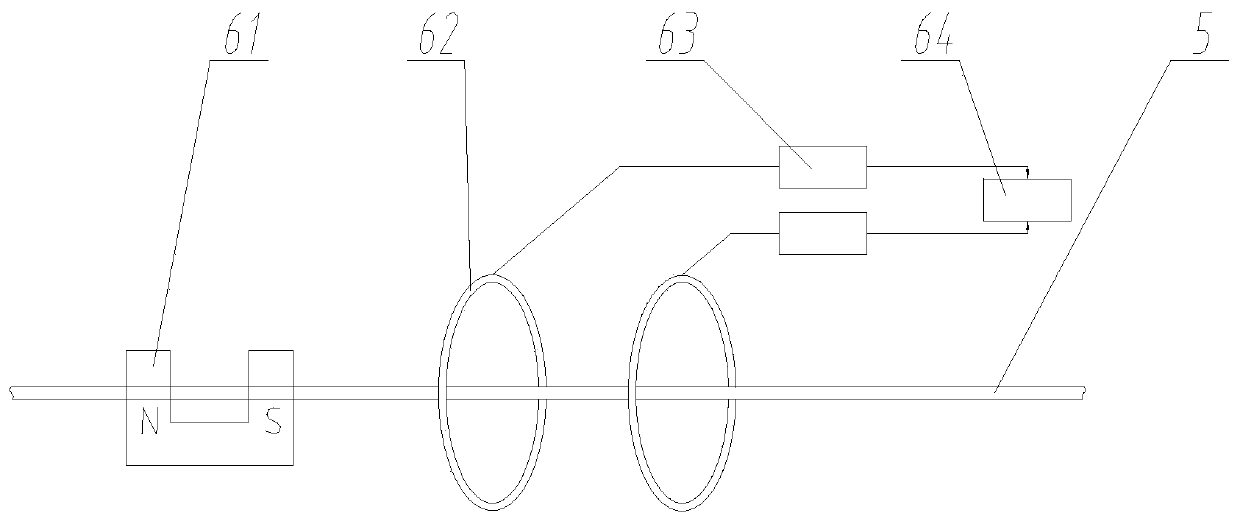

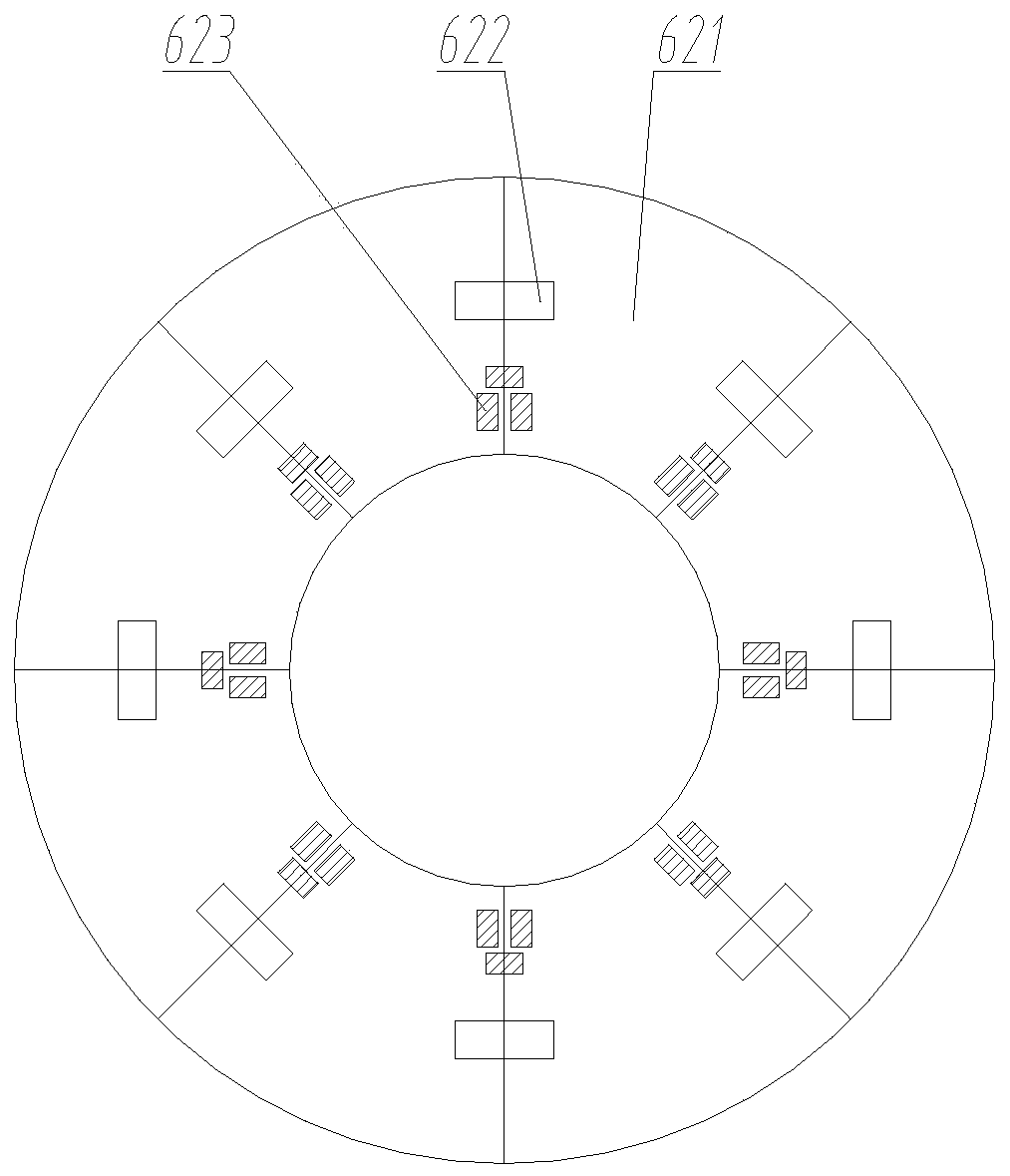

[0097] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, the hoist wire rope broken wire detection experimental system and its detection method include a base plate 1, a first support device, a second support device, a third support device and a detection device 6;

[0098] The first supporting device is a pair, and is symmetrically arranged at the left and right ends of the bottom plate 1, and each group of first supporting devices includes a first supporting column 21 vertically arranged on the bottom plate 1 and a pair of vertically arranged and rotatably mounted on the second A support wheel 22 on a support column 21;

[0099] The second support device is arranged in the middle of the base plate 1, and includes a second support column 31 vertically arranged on the base plate 1 and a drive wheel 33 rotatably mounted on the second support column 31, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com