A method for plugging conductive resin in blind holes of conductive substrate

A conductive substrate and conductive resin technology, which is applied in the manufacture of printed circuits, electrical components, printed circuits, etc., can solve problems such as increased on-resistance, affecting product use, conductive resin ink voids, etc., and achieves the effect of smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

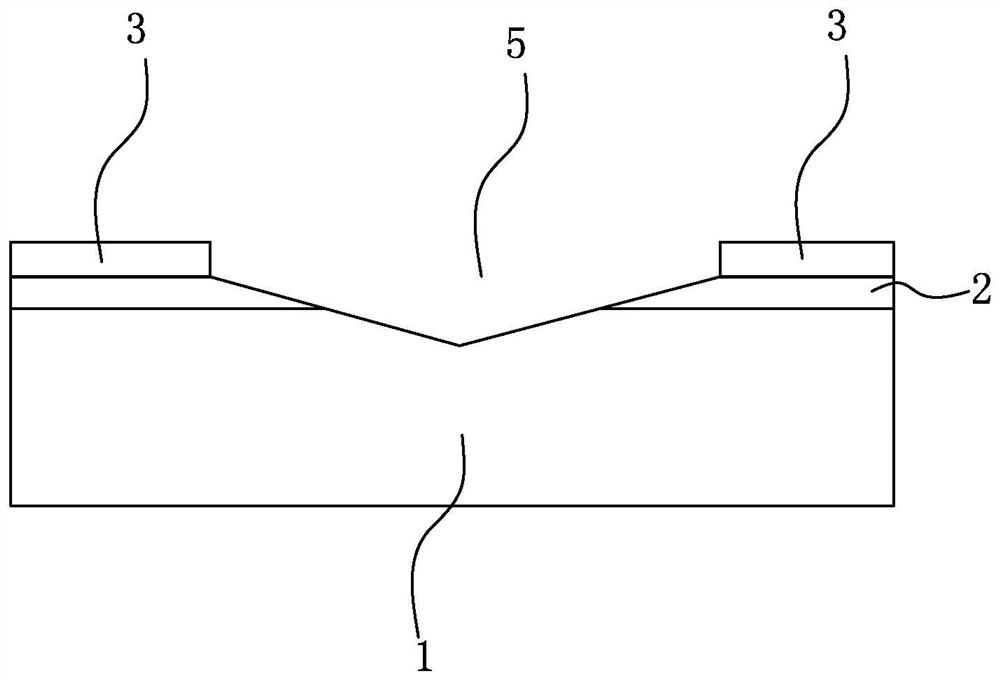

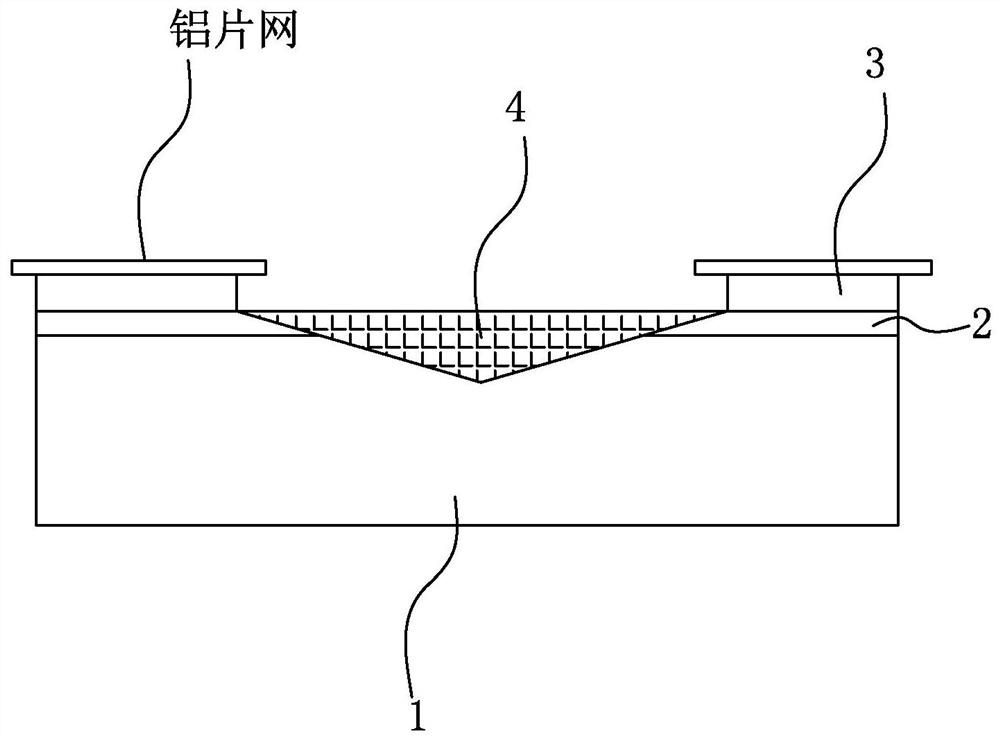

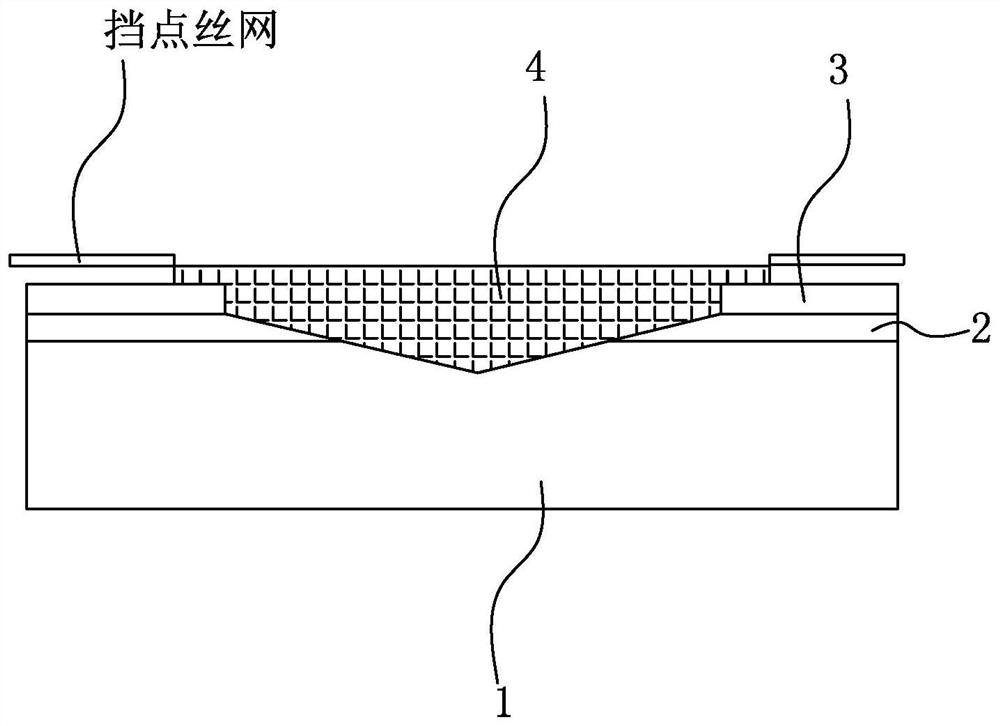

[0024] Such as Figure 1 to Figure 4 Drawings of embodiments of the invention.

[0025] A method for plugging conductive resin in blind holes of a conductive substrate, comprising the following steps:

[0026] Step 1: Drilling blind holes at positions where conduction is required on the conductive substrate, and the blind holes penetrate at least two conductive layers of the conductive substrate.

[0027] Step 2: After the blind hole is drilled, the top of the conductive substrate is removed. The non-woven grinding plate is used to remove the edge of the conductive substrate, so that the subsequent filling and other work can be carried out smoothly.

[0028] Step 3: A copper foil layer is provided on one side of the conductive sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com