Microcapsule curry powder, boiling-resistant curry sauce and manufacture method thereof

A production method and technology of curry powder, which are applied in the fields of food ingredients as odor improvers, food shaping, food science, etc., can solve problems such as difficulty in maintaining fragrance, weak cooking resistance, weak fragrance, etc., and achieve film-forming properties Good stability, strong cooking resistance, and the effect of preventing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

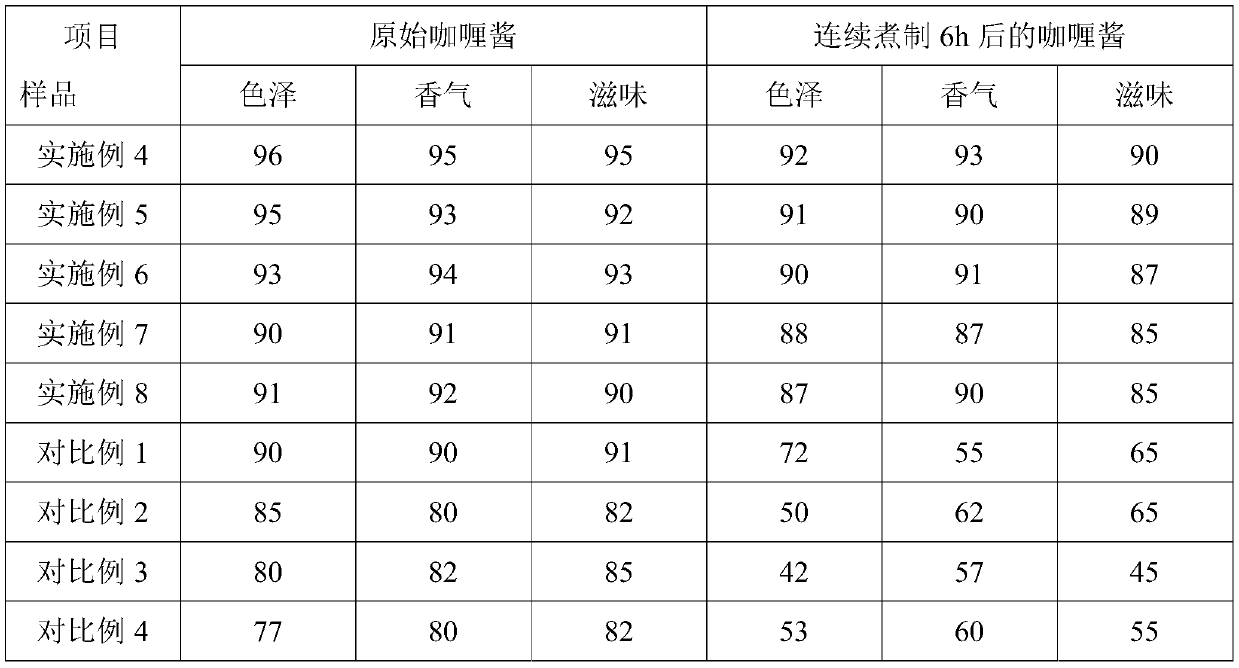

Examples

Embodiment 1

[0028] A microcapsule curry powder comprises the following raw materials in parts by weight: 35 parts of curry powder, 6 parts of modified starch, 2 parts of chitosan, and 5 parts of fish gelatin; wherein, each part by weight is calculated as 1 g. Its specific preparation method includes: mixing curry powder, modified starch, chitosan and fish gelatin to obtain a mixture; adding water 0.2 times the total weight of the mixture for beating, followed by homogeneous emulsification, and then spray drying to obtain .

Embodiment 2

[0030] A microcapsule curry powder comprises the following raw materials in parts by weight: 42 parts of curry powder, 5 parts of modified starch, 5 parts of chitosan, and 7 parts of fish gelatin; wherein, each part by weight is calculated as 2 g. Its specific preparation method includes: mixing curry powder, modified starch, chitosan and fish gelatin to obtain a mixture; adding water 0.5 times the total weight of the mixture for beating, followed by homogeneous emulsification, and then spray drying to obtain .

Embodiment 3

[0032] A microcapsule curry powder comprises the following raw materials in parts by weight: 50 parts of curry powder, 8 parts of modified starch, 3 parts of chitosan, and 10 parts of fish gelatin; wherein, each part by weight is calculated as 5 g. Its specific preparation method includes: mixing curry powder, modified starch, chitosan and fish gelatin to obtain a mixture; adding water 0.8 times the total weight of the mixture for beating, followed by homogeneous emulsification, and then spray drying to obtain .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com