Customized slice shape forming machine adopting roll cutting

A molding machine and roller cutting technology, applied in the treatment of tobacco, tobacco, application, etc., can solve the problems affecting the efficiency and quality of cigarettes, uneven length and width of leaves, and excessively large sheet shapes, so as to eliminate large and super large pieces of tobacco leaves, Good effect and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

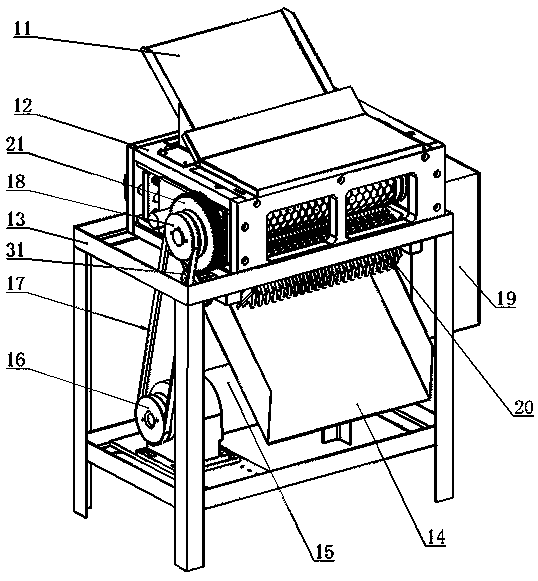

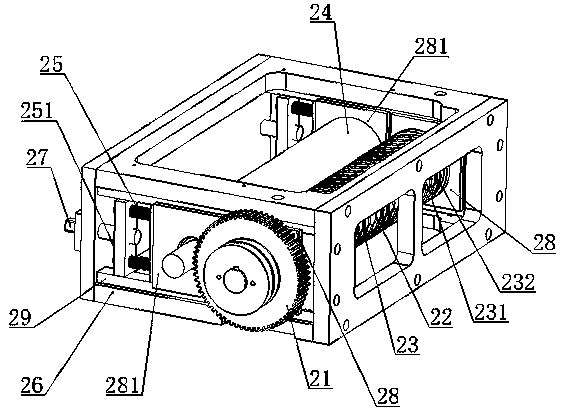

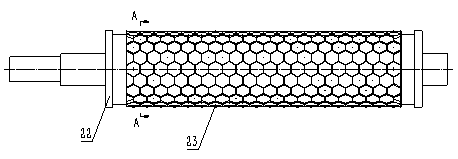

[0030] Such as Figure 1 to Figure 10 shown. A roller cutting custom-made sheet forming machine of the present invention includes a roller cutting assembly 12 and a power transmission device. The roller cutting assembly 12 is composed of a slicing seat 26, a driving cutting roller 22, a driven smooth roller 24, a differential speed rejecting device 20 and a driven smooth roller elastic pressing mechanism.

[0031] The slice seat 26 is a rectangular frame seat body, which is installed and fixed on the frame 13 . The upper and lower ends of the two opposite sides of the slice seat 26 are provided with matching guide rails 29 .

[0032] Frame 13 is a rectangular frame frame, and motor 15 is fixedly installed in the bottom of frame 13, and small belt pulley 16 is arranged on motor 15. A control box 19 is fixed on the side of the frame 13, and the control box 19 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com