Special filter thickener of wastewater

A concentrator and waste water technology, which is applied in the direction of filtration separation, mobile filter element filter, semi-permeable membrane separation, etc., can solve the problems of failing to meet discharge requirements, low liquid solid content, and inability to re-use, etc., to increase work Efficiency, clear filtrate, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

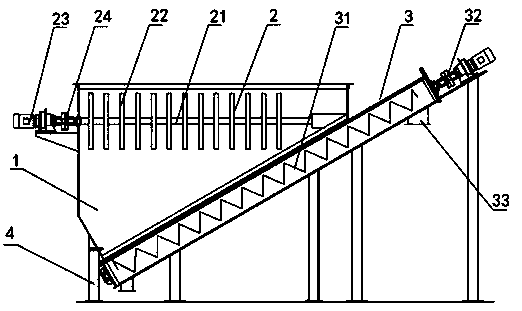

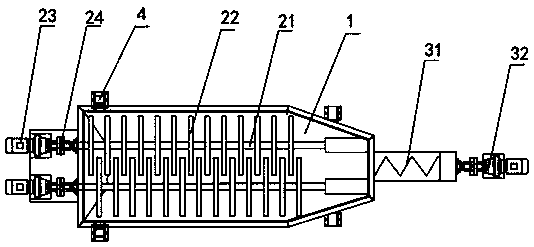

[0028] Please refer to figure 1 with figure 2 , the present invention provides a filter concentrator for waste water, comprising a silo 1, a stirring and filtering device 2, a slag removing device 3 and a support foot 4, the agitating and filtering device 2 is installed in the hopper 1, and the slag removing device 3 is installed in the hopper At the bottom of the bin 1, the supporting feet 4 are installed at the bottom of the bin 1 and the slag removal device 3 to support the entire filter thickener.

[0029] Stirring filter device 2 comprises hollow main shaft 21, filter impeller 22, main drive reducer 23 and shaft coupling 24; On one side wall, it runs through the entire silo 1. The filter impeller 22 has a hollow structure and the number is at least 2. The fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com