Red mud leaching slag washing tank and application method thereof

A technology for leaching slag and red mud, applied in chemical equipment and process fields, can solve problems such as unfavorable recovery, difficulty in filtration, loss, etc., and achieve the effects of fast filtration, good effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

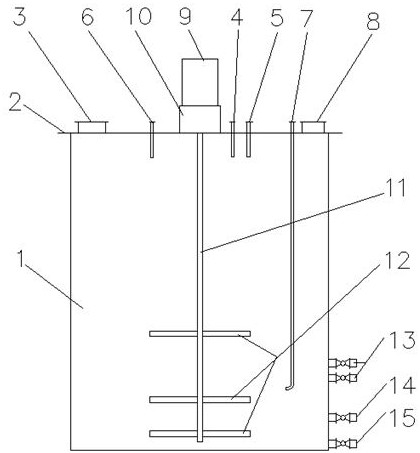

[0025] like figure 1 As shown, the red mud leaching slag washing tank and its use method of the present invention are as follows:

[0026] 1. The tank body (1) of the leaching slag washing tank is cylindrical, and the upper top cover (2) is provided with an observation hole (3), a red mud slurry adding pipe (4), a hydrochloric acid adding pipe (5), washing water Adding pipe (6), heating steam adding pipe (7), exhaust pipe (8), stirring motor (9) and reducer (10) with frequency conversion speed regulator, stirring shaft (11) and stirring paddle are set in the tank Leaf (12), on the side of the tank near the bottom of the tank, there are suspension outlet (13) with valve control, leach slag outlet (14) with valve control, heavy sand mineral outlet with valve control ( 15), wherein the heavy sand mineral outlet (15) with valve control can also be used as a cleaning port.

[0027] 2. After beating the red mud and slag washing water, put them into the leaching slag washing tank t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com