Aluminum plastic film with low warping degree after deep punching and high heat sealing strength as well as preparation method thereof

An aluminum-plastic film, low warpage technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of liquid leakage, insufficient heat sealing strength, etc., and achieve simple processing technology, low warpage, Product safety and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

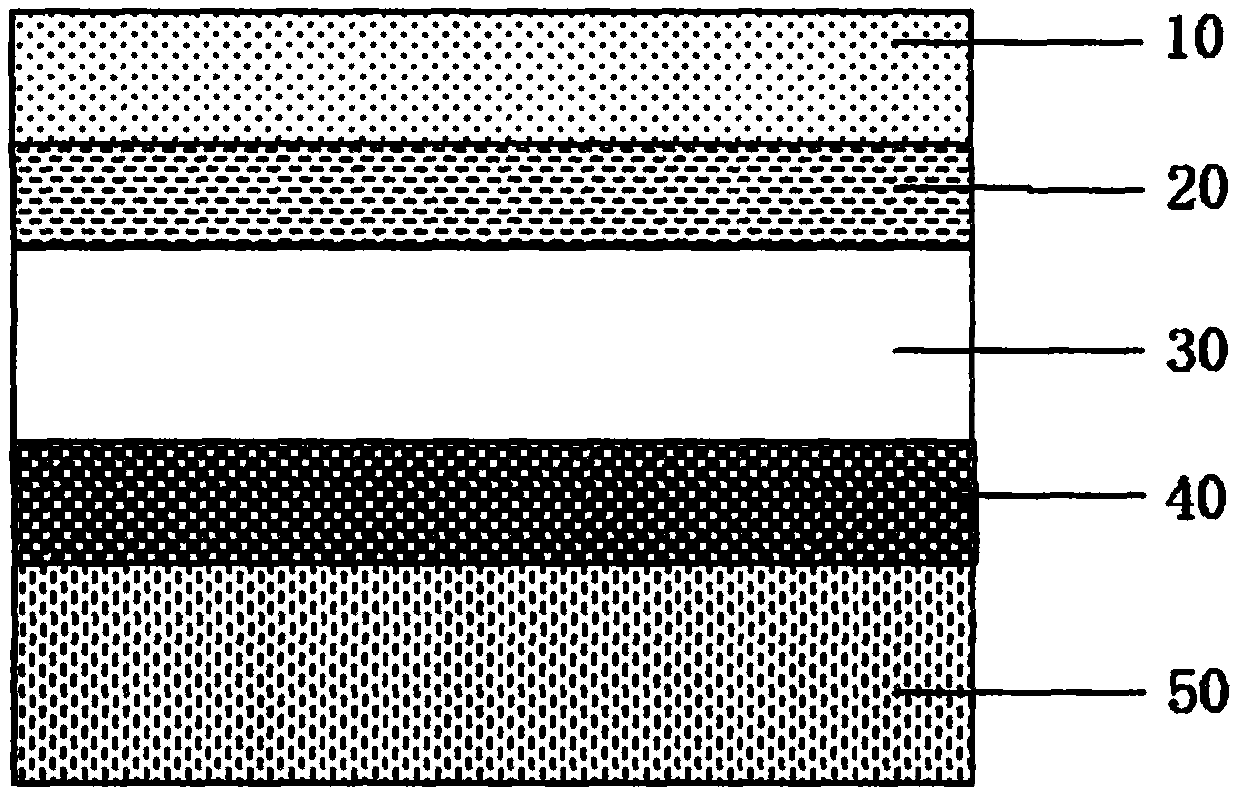

[0033] The aluminum-plastic film structure with low warpage after drawing is a polyamide film layer 10 with a thickness of 25 μm, a tensile strength of 208 MPa, an elongation at break of 127%, a first adhesive layer 20 of 3 μm, an aluminum foil layer 30 of 40 μm, The tensile strength of the second adhesive layer 40 of 3 μm and the polypropylene thin film layer 50 of 40 μm is 47 MPa, and the elongation at break is 327%.

Embodiment 2

[0035] The structure of the aluminum-plastic film with low warpage after drawing is a polyamide film layer 10 with a thickness of 25 μm, a tensile strength of 228 MPa, an elongation at break of 130%, a first adhesive layer 20 of 3 μm, an aluminum foil layer 30 of 40 μm, The tensile strength of the 3 μm second adhesive layer 40 and the 40 μm polypropylene thin film layer 50 is 45 MPa, and the elongation at break is 377%.

Embodiment 3

[0037] The aluminum-plastic film structure with low warpage after drawing is a polyamide film layer 10 with a thickness of 25 μm, a tensile strength of 251 MPa, an elongation at break of 124%, a first adhesive layer 20 of 3 μm, an aluminum foil layer 30 of 40 μm, The tensile strength of the second adhesive layer 40 of 3 μm and the polypropylene thin film layer 50 of 40 μm is 53 MPa, and the elongation at break is 346%. Comparative example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com