Electric automobile battery voltage detection system

A technology for battery voltage detection and electric vehicles, applied in electric vehicles, measuring current/voltage, battery/fuel cell control devices, etc., can solve the problems of long time for disassembly, etc., and achieve simple structure, convenient maintenance and convenient measurement quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

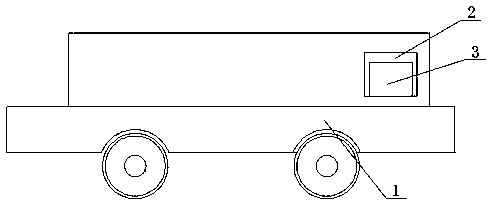

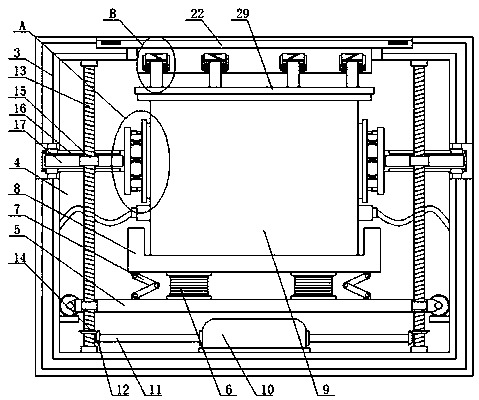

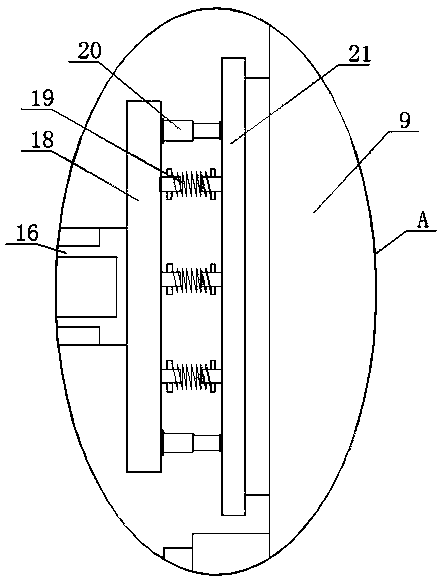

[0031] refer to Figure 1-6 , a battery voltage detection system for an electric vehicle, comprising a car body 1, a battery 9, a voltage conversion module, a reference voltage module, a comparator, a controller, a voltage divider module and an alarm unit, the battery 9, a voltage conversion module, a reference voltage module, The comparator, the controller, the voltage divider module and the alarm unit are connected in series, the car body 1 is provided with an engine compartment 2, the bottom inner wall of the engine compartment 2 is fixedly installed with a mounting seat 3, and the mounting seat 3 is provided with an installation cavity 4, and the installation The same moving plate 5 is slidably connected to the inner walls of both sides of the cavity 4, and the top of the moving plate 5 is fixedly equipped with two first springs 6 and two rotating parts 7 arranged symmetrically, and the two rotating parts 7 and the two second rotating parts The top of a spring 6 is fixedly...

Embodiment 2

[0042] refer to Figure 1-6 , a battery voltage detection system for an electric vehicle, comprising a car body 1, a battery 9, a voltage conversion module, a reference voltage module, a comparator, a controller, a voltage divider module and an alarm unit, the battery 9, a voltage conversion module, a reference voltage module, The comparator, the controller, the voltage divider module and the alarm unit are connected in series, the car body 1 is provided with an engine compartment 2, the bottom inner wall of the engine compartment 2 is welded with a mounting seat 3, and the mounting seat 3 is provided with an installation cavity 4, the installation cavity The same moving plate 5 is slidably connected to the inner walls of both sides of 4, and the top of the moving plate 5 is welded with two first springs 6 and two rotating parts 7 arranged symmetrically, and the two rotating parts 7 and the two first springs The top of 6 is welded with the same U-shaped plate 8, a battery 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com