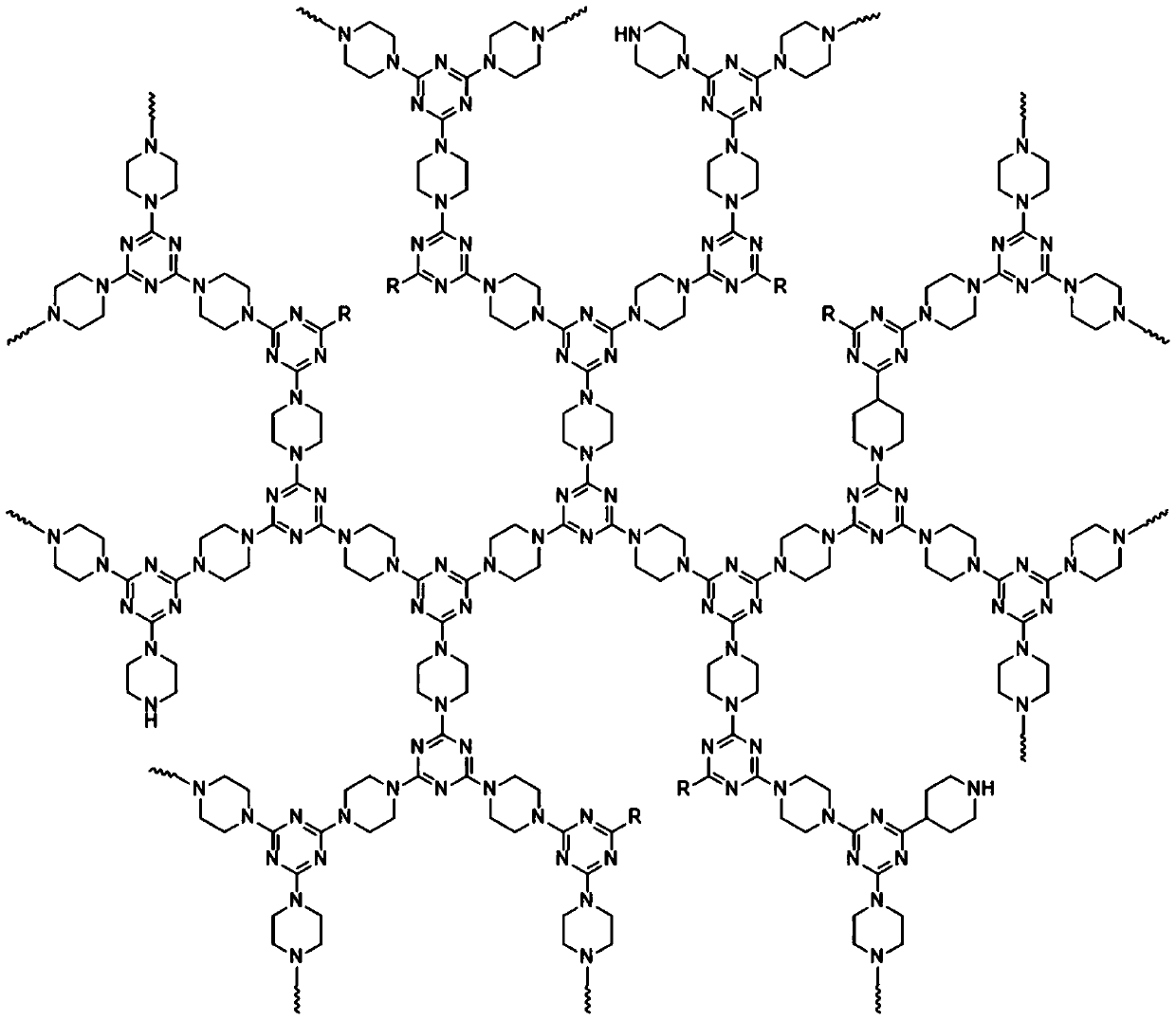

High-thermal stability macromolecular char-forming agent CPCA, preparation method, composition and application thereof

A technology with high thermal stability and macromolecules, which is applied in the field of flame retardant materials, can solve the problems affecting the mechanical properties of materials, large additions, large water solubility, etc., and achieve simple and efficient preparation methods, weakened combustion strength, and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

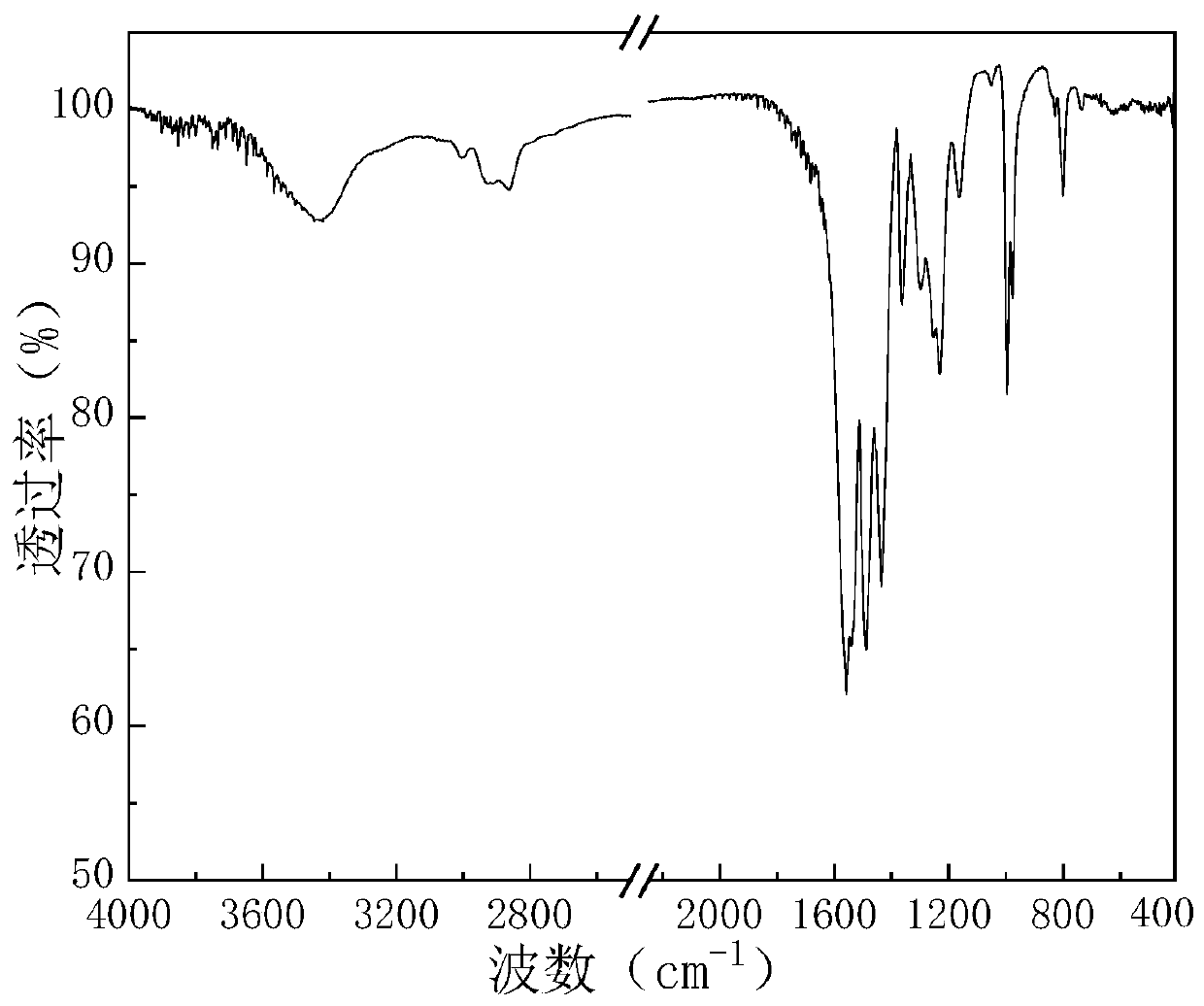

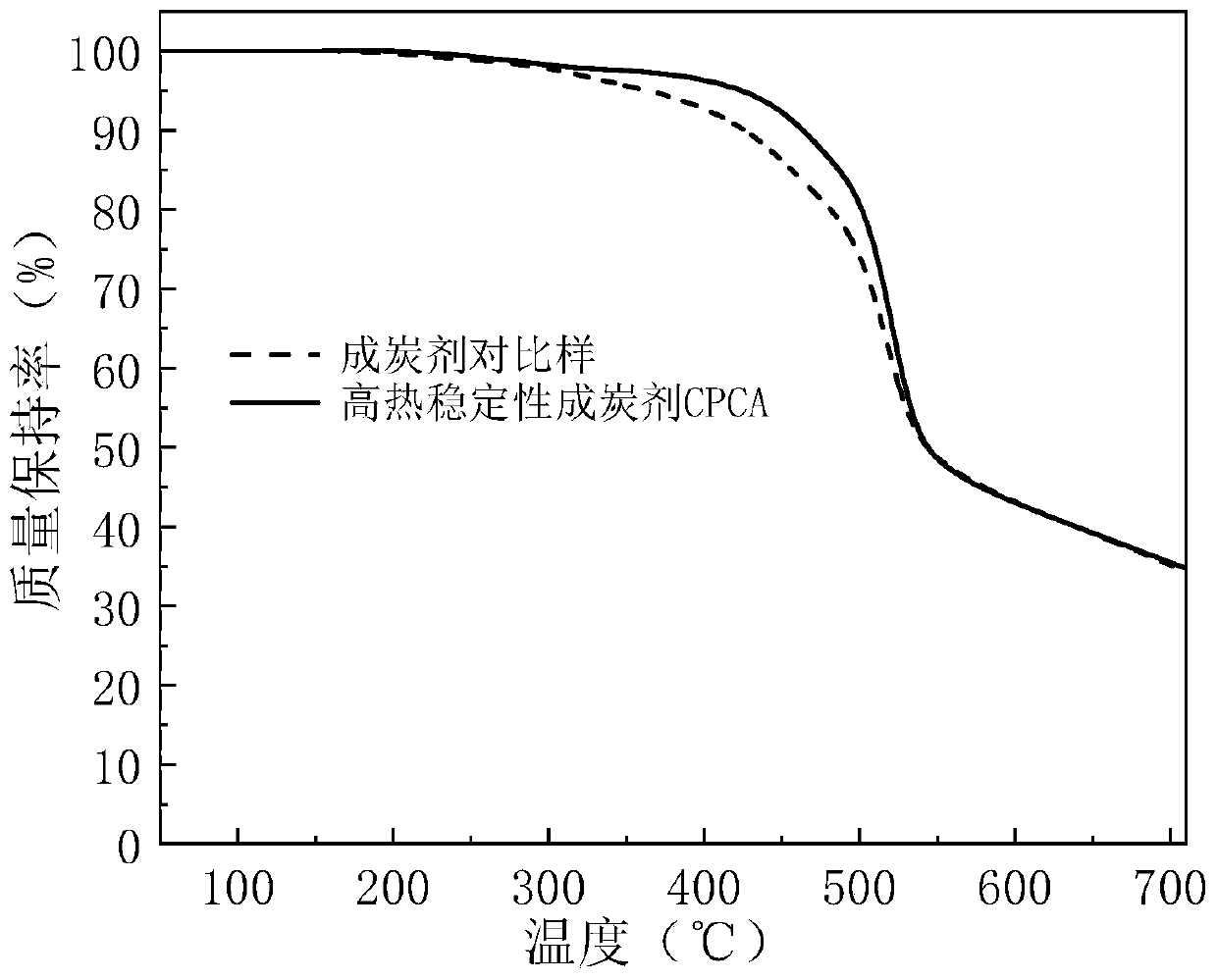

Embodiment 1

[0031] 17.23g (0.20mol) of anhydrous piperazine and 330ml of chlorobenzene were added to the reaction vessel and stirred for dissolution, and 37.45g (0.35mol) of anhydrous sodium carbonate acid-binding agent was added to the reaction vessel; then 18.44g (0.10mol) of three Polycyanuric chloride is dissolved in 200ml of chlorobenzene solvent, 0.79g (0.01mol) pyridine is dissolved in 20ml of chlorobenzene solvent; At 25 ℃, the chlorobenzene solution containing cyanuric chloride is dripped into the reaction at a speed of 5ml / min. In the container, after the dropwise addition, the temperature of the reaction system was raised to 100°C for 1 hour, and then the pyridine solution was added to the system for 7 hours of reaction. After the reaction was completed, it was filtered and washed with water, each time for 25 minutes. After repeated washing for five times, it was dried to obtain high heat Stable macromolecular char-forming agent CPCA, the yield is 99.1%, and the temperature corr...

Embodiment 2

[0033] 25.84g (0.30mol) of anhydrous piperazine and 300ml of dioxane were added to the reaction vessel and stirred to dissolve, and 64.2g (0.6mol) of anhydrous sodium carbonate acid-binding agent was added to the reaction vessel; then 33.18g (0.18mol) ) cyanuric chloride is dissolved in 300ml dioxane solvent, 1.5g (0.025mol) urea is dissolved in 20ml dioxane solvent; Dioxane solution was dropped into the reaction container. After the dropwise addition, the reaction system was heated to 95°C for 4 hours, and then the urea solution was added to the system to react for 2 hours. After the reaction was completed, suction filtration and water washing were performed, and the washing was repeated for 20 minutes each time. After four times, the target product CPCA was obtained by drying, the yield was 98.1%, and the temperature corresponding to 5% of its decomposition was 424°C; the CPCA of 6wt.%, the ammonium polyphosphate of 25wt.% were uniformly mixed, and then mixed with 69wt.% The...

Embodiment 3

[0035] Add 25.84g (0.30mol) of anhydrous piperazine and 350ml of tetrahydrofuran into the reaction vessel and stir to dissolve, add 50.5g (0.5mol) of triethylamine acid-binding agent into the reaction vessel; Dissolve cyanogen in 300ml tetrahydrofuran solvent, dissolve 1.8g (0.03mol) ethylenediamine in 15ml tetrahydrofuran solvent; drop the dioxane solution containing cyanuric chloride into the reaction at a speed of 5ml / min at 30°C In the container, after the dropwise addition, the temperature of the reaction system was raised to 95°C for 7 hours, and then ethylenediamine solution was added to the system for 1 hour of reaction. After the reaction was completed, suction filtration and water washing were performed for 25 minutes each time. After repeated washing four times, it was dried Obtain the target product CPCA, the yield is 99.0%, and the temperature corresponding to its decomposition of 5% is 423°C; 3wt.% CPCA, 22wt.% ammonium polyphosphate are uniformly mixed, and then ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap