Vibrating watertight backfilling method of foundation pit pipe ditches

A vibrating watertight and pipe trenching technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of difficulty in meeting the requirements of specifications and design for compaction, the thickness of layers should not be too large, and the construction efficiency is low. The effect of avoiding late settlement, saving construction period and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

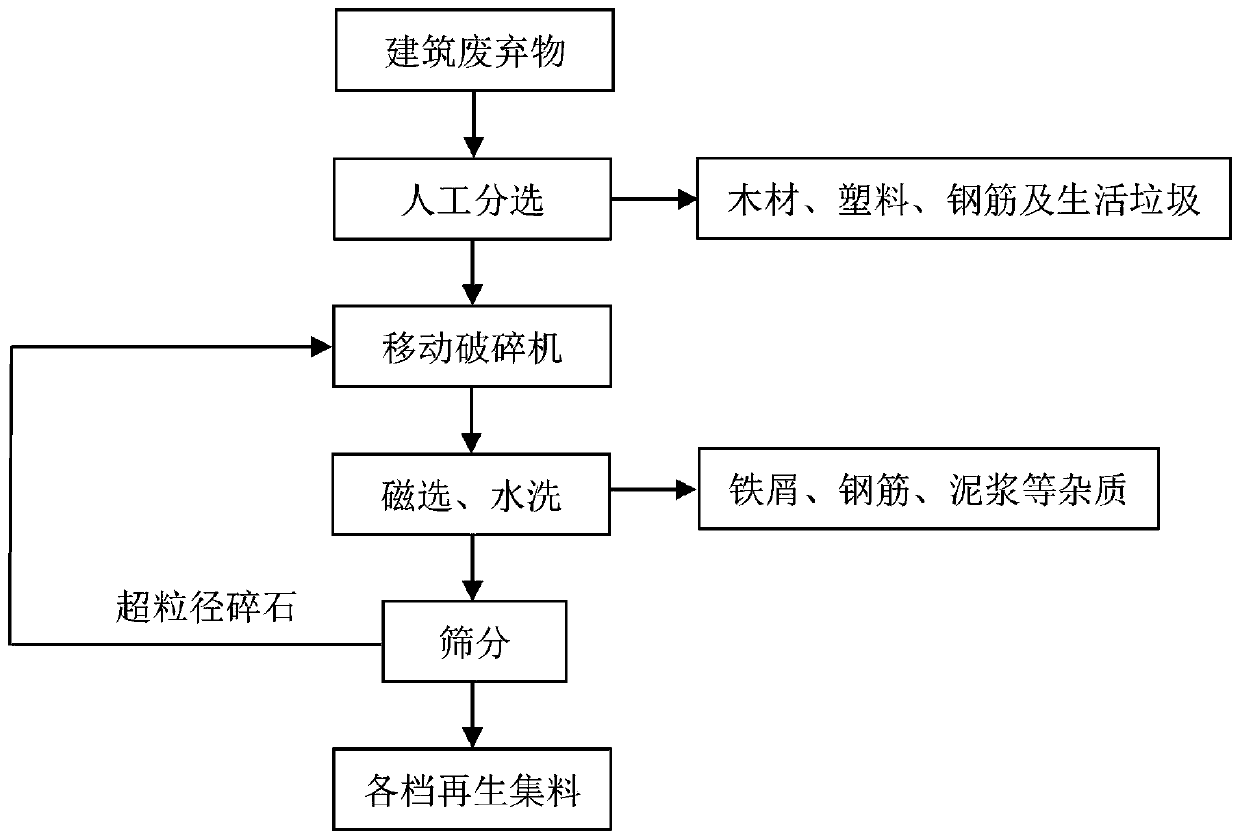

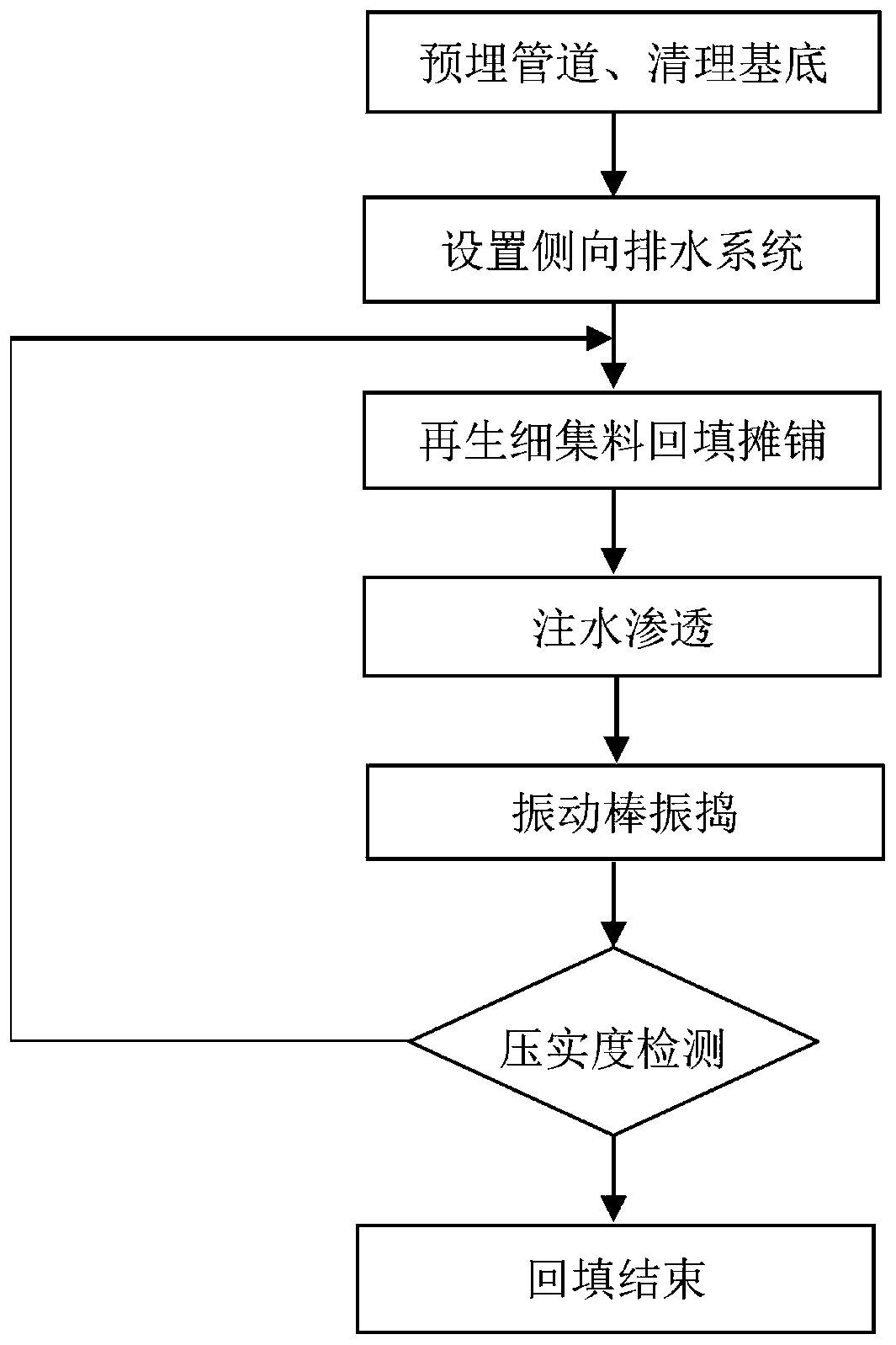

[0034] refer to Figure 1-2 , the vibrating watertight backfilling method of the pipe ditch of the foundation pit, which specifically includes the following steps:

[0035] S1: In the production stage of recycled materials, firstly, the construction waste is pretreated and sorted, and the wood, plastic, steel bars and domestic waste in the construction waste are removed through manual sorting;

[0036] S2: use the mobile crusher to crush the construction waste sorted in S1, so that the particle size of the crushed construction waste material is 1-10mm;

[0037] S3: Precisely sort the construction waste materials in S2, and remove iron filings and mud impurities in the materials by means of magnet adsorption and water washing;

[0038] S4: The material is further screened by controlling the size of the screen, used to prepare recycled aggregates of different specifications, and placed aside for use;

[0039] S5: In the backfilling stage of recycled materials, first connect th...

Embodiment 2

[0046] refer to Figure 1-2 , the vibrating watertight backfilling method of the pipe ditch of the foundation pit, which specifically includes the following steps:

[0047] S1: In the production stage of recycled materials, firstly, the construction waste is pretreated and sorted, and the wood, plastic, steel bars and domestic waste in the construction waste are removed through manual sorting;

[0048] S2: Use the mobile crusher to crush the construction waste sorted in S1, so that the particle size of the crushed construction waste material is 20-30mm;

[0049] S3: Precisely sort the construction waste materials in S2, and remove iron filings and mud impurities in the materials by means of magnet adsorption and water washing;

[0050] S4: The material is further screened by controlling the size of the screen, used to prepare recycled aggregates of different specifications, and placed aside for use;

[0051] S5: In the backfilling stage of recycled materials, first connect t...

Embodiment 3

[0058] refer to Figure 1-2 , the vibrating watertight backfilling method of the pipe ditch of the foundation pit, which specifically includes the following steps:

[0059] S1: In the production stage of recycled materials, firstly, the construction waste is pretreated and sorted, and the wood, plastic, steel bars and domestic waste in the construction waste are removed through manual sorting;

[0060] S2: Use the mobile crusher to crush the construction waste sorted in S1, so that the particle size of the crushed construction waste material is 20-30mm;

[0061] S3: Precisely sort the construction waste materials in S2, and remove iron filings and mud impurities in the materials by means of magnet adsorption and water washing;

[0062] S4: The material is further screened by controlling the size of the screen, used to prepare recycled aggregates of different specifications, and placed aside for use;

[0063] S5: In the backfilling stage of recycled materials, first connect t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com